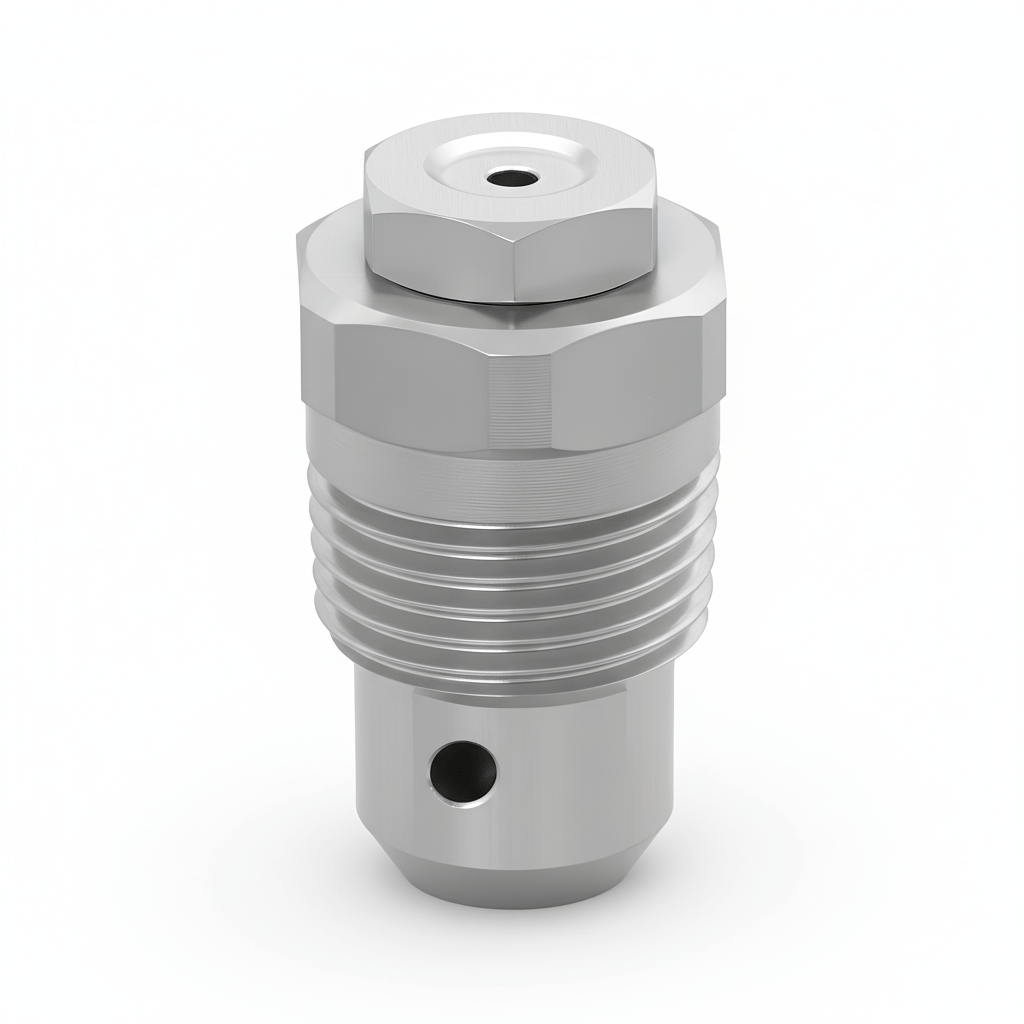

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 25 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 7.5 |

| Orifice Diameter. Nom. (in) | 0.297 |

| Inlet Connection Size (in.) | 3/4 |

| Hex Size (mm) | 27 |

| Inlet Dia. Nom. (mm) | 7.1 |

| Inlet Dia. Nom. (in) | 0.281 |

Description

Product Overview

When cement crews manage specialty applications, the NPBD-25-3/4-316 lets each quality manager ensure consistent coverage through its precision hollow cone spray pattern. Constructed from 316L stainless steel, this nozzle withstands corrosive environments common in industrial operations. Operators install it via the 3/4-inch inlet, integrating it seamlessly into existing fluid delivery systems. The uniform spray distribution helps maintain process control, reducing variability in surface treatment or cooling processes.

Applications

In cooling & quenching operations, the nozzle delivers a finely atomized spray that enhances heat dissipation and prevents equipment overheating. For dust & pollution control, the precise hollow cone pattern aids in efficient particulate suppression, improving air quality and regulatory compliance.

Industries

Sectors such as building materials, mining, and cement rely on the NPBD-25-3/4-316 for its ability to manage harsh conditions and maintain spray uniformity. Manufacturing & assembly and roofing industries also utilize this nozzle to meet their specific fluid handling and corrosion resistance requirements.