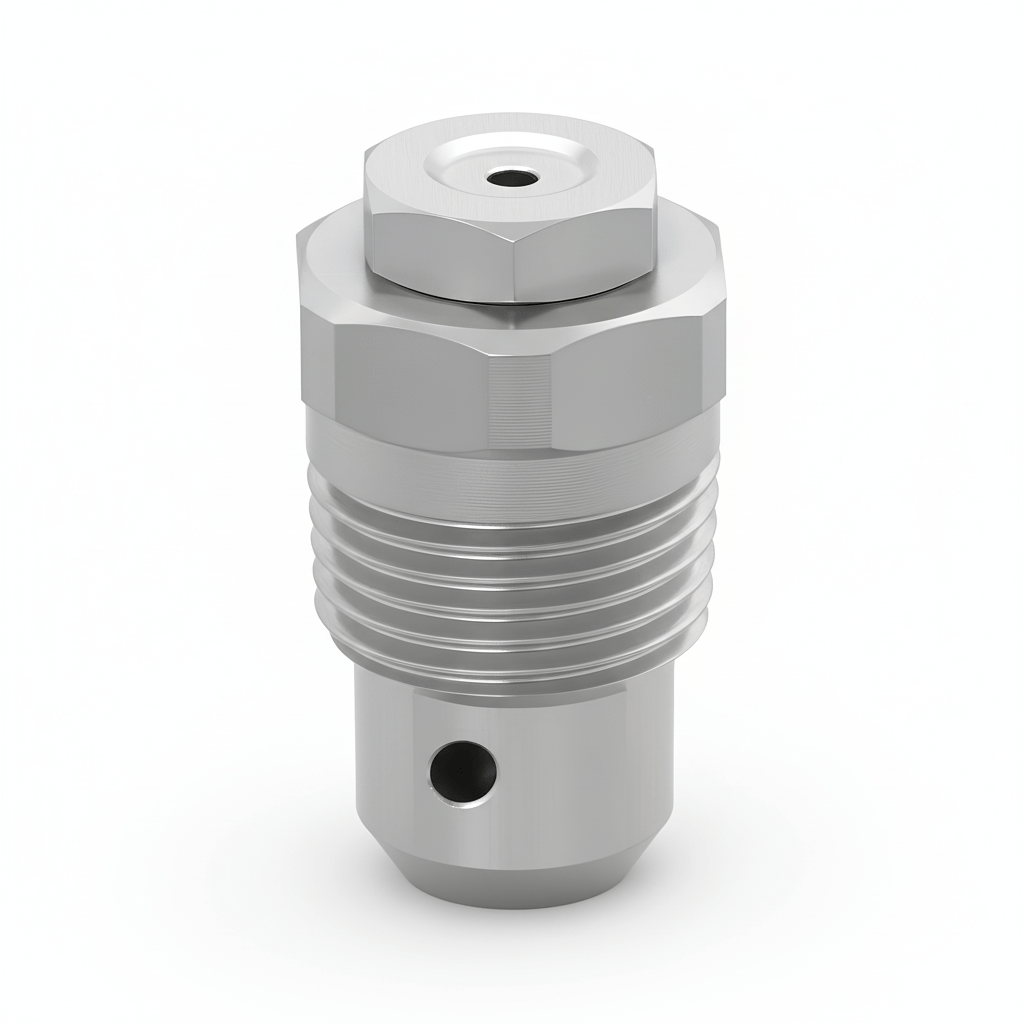

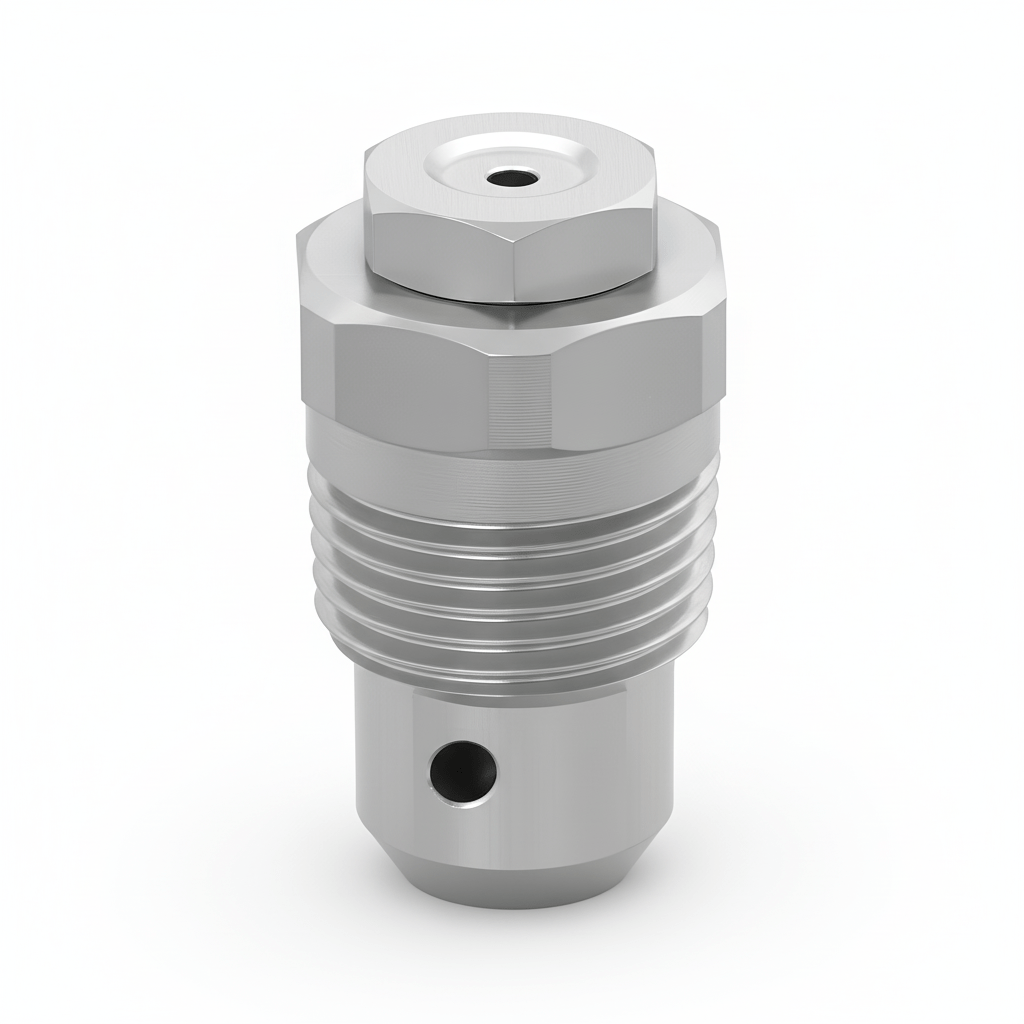

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 120 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 18.3 |

| Orifice Diameter. Nom. (in) | 0.719 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

A process engineer in the Energy facility uses the NPBD-120-1-1/2-316 during cooling & quenching to deliver a consistent hollow cone spray that evenly covers surfaces requiring temperature control. Constructed from 316L stainless steel, the nozzle withstands corrosive environments typical of industrial fluids. The 1-1/2 inch inlet allows integration with existing piping systems, ensuring stable flow rates and minimal maintenance interruptions. By maintaining uniform spray distribution, the operator reduces hotspots and improves overall process reliability.

Applications

In cooling & quenching operations, the NPBD-120-1-1/2-316 nozzle facilitates rapid heat dissipation, which helps maintain material integrity and operational efficiency. Additionally, its use in dust & pollution control supports environmental compliance by effectively suppressing airborne particulates at the source.

Industries

This nozzle is well-suited for industries such as building materials, mining, cement, and manufacturing & assembly, where corrosion resistance and uniform spray coverage are critical. Facilities in roofing and Energy sectors also rely on it to ensure consistent application under demanding conditions.