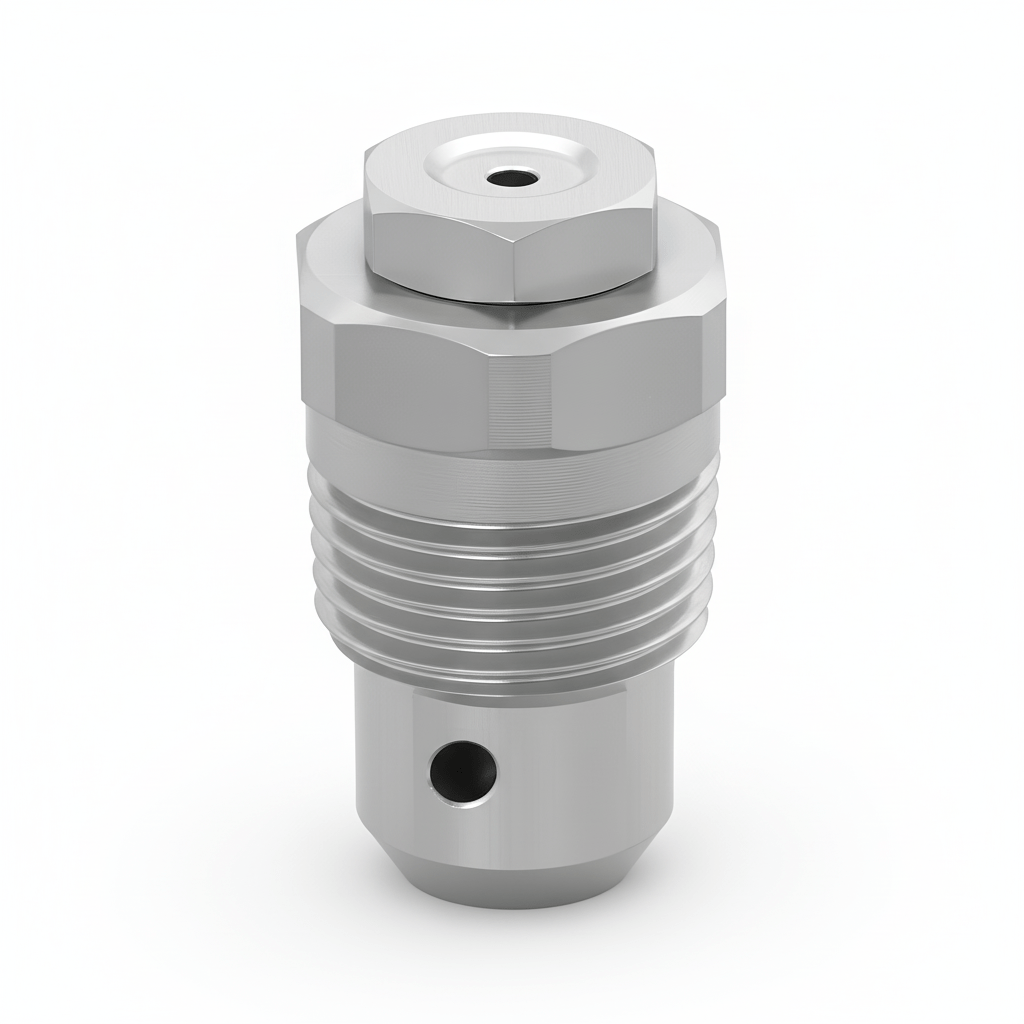

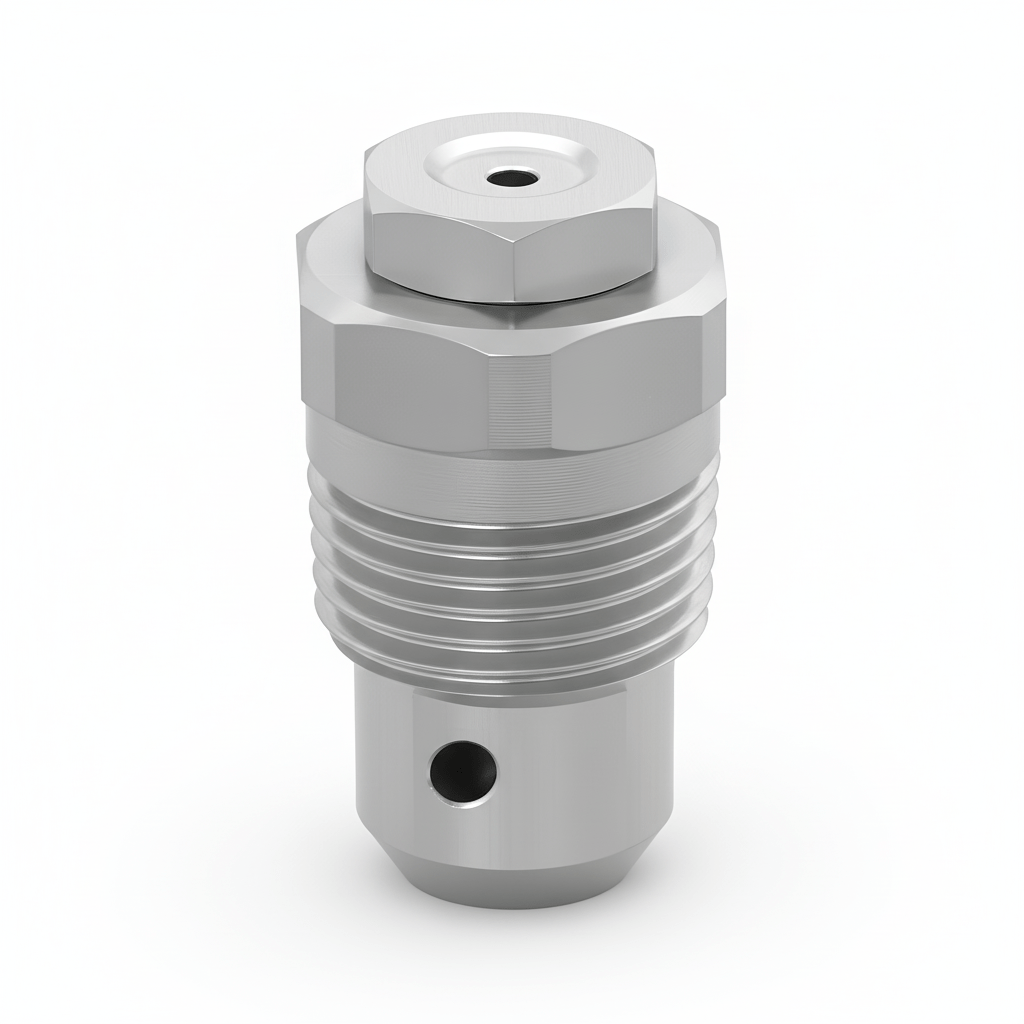

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 110 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 17.1 |

| Orifice Diameter. Nom. (in) | 0.672 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

Inside the mining line's dust & pollution control stage, a process engineer relies on the NPBD-110-1-1/2-SS to deliver consistent hollow cone spray patterns that optimize particulate suppression. Constructed from 303/304 stainless steel, the nozzle withstands corrosive environments while maintaining uniform coverage. During setup, the engineer connects the 1-1/2 inch inlet to high-pressure piping, verifying flow rates to ensure targeted dispersion efficiency. This precise spray control reduces airborne dust concentrations and enhances air quality compliance in real-time operations.

Applications

The NPBD-110-1-1/2-SS proves effective in cooling & quenching processes by providing uniform liquid distribution across heated surfaces, facilitating rapid temperature reduction. Additionally, its role in dust & pollution control supports environmental management objectives by minimizing fugitive emissions from industrial equipment.

Industries

Sectors such as building materials, mining, cement, and manufacturing & assembly rely on the NPBD-110-1-1/2-SS for its durability and reliable spray distribution in harsh conditions. The roofing and Energy industries also utilize this nozzle to improve process consistency and extend equipment life through corrosion-resistant design.