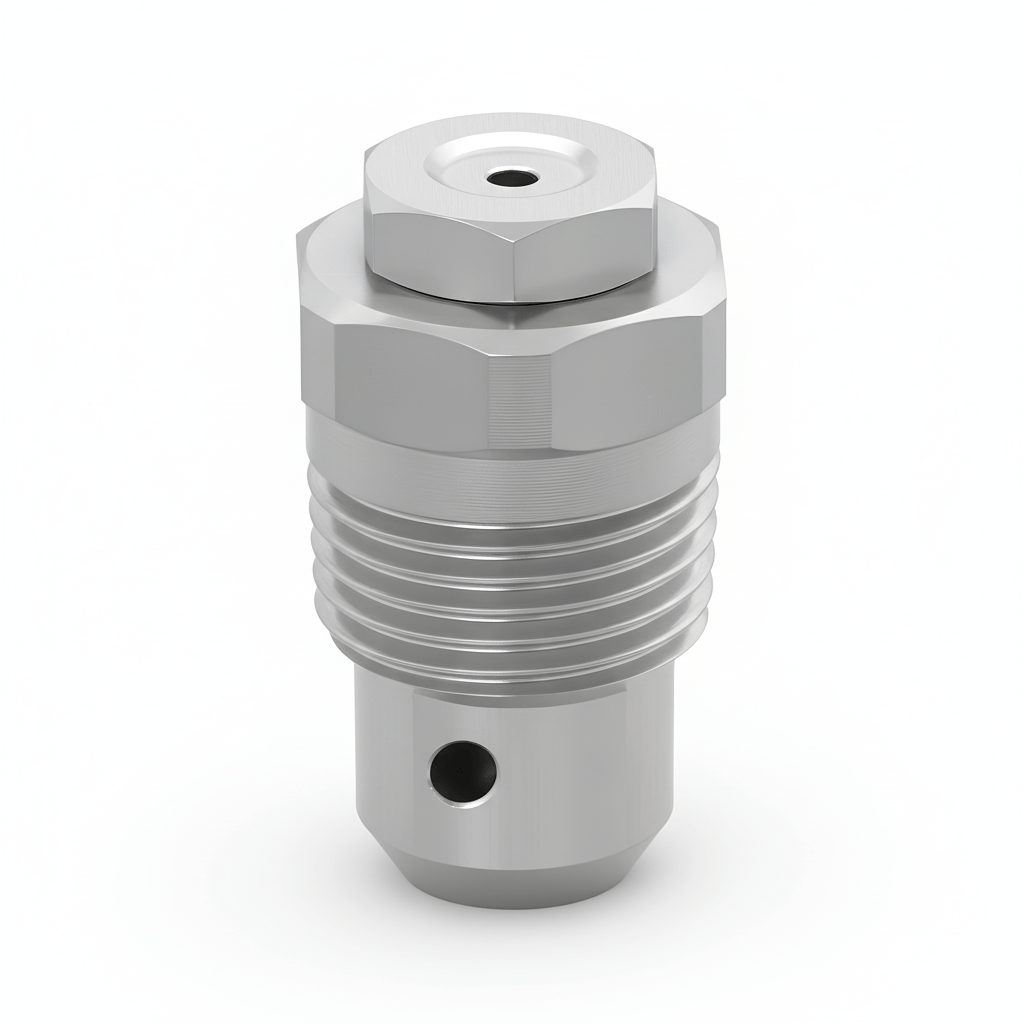

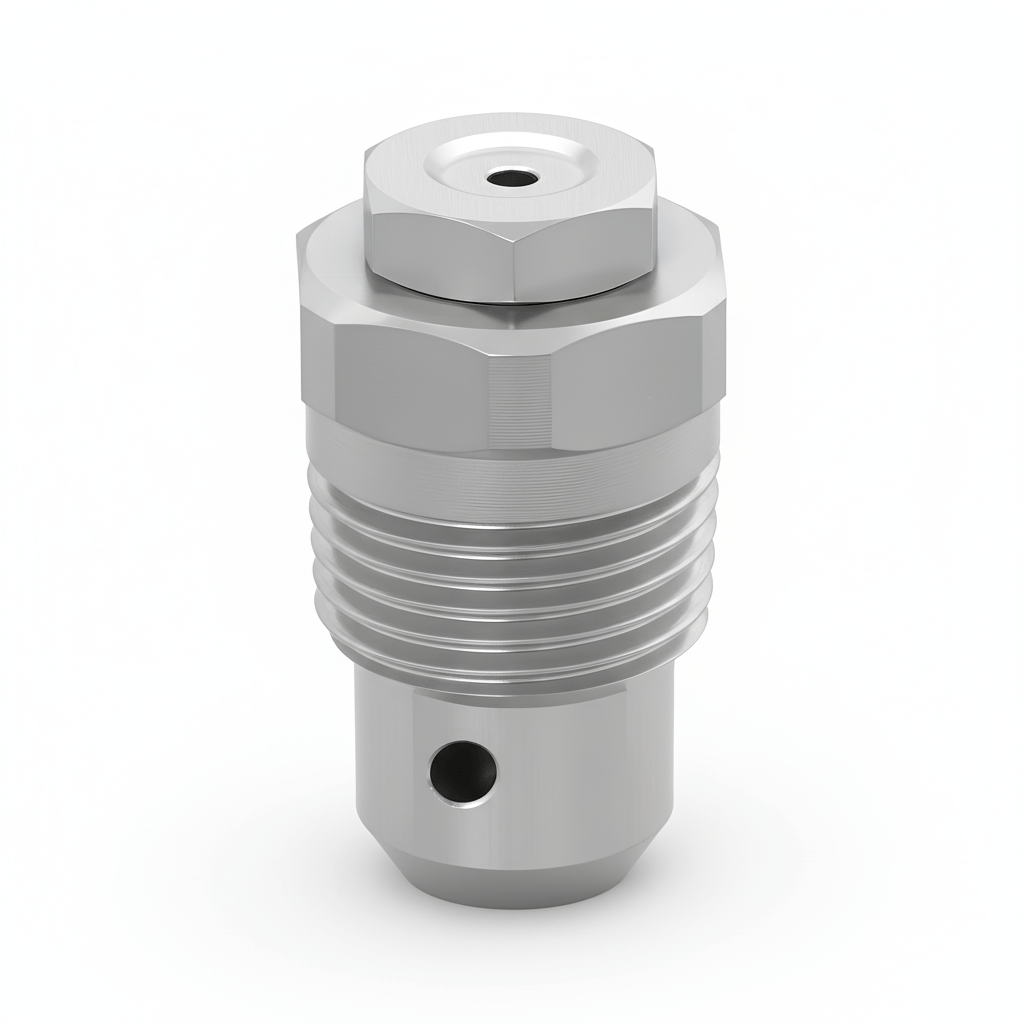

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 110 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 17.1 |

| Orifice Diameter. Nom. (in) | 0.672 |

| Inlet Connection Size (in.) | 1-1/2 |

| Hex Size (mm) | 50.8 |

| Inlet Dia. Nom. (mm) | 9.5+ |

| Inlet Dia. Nom. (in) | 0.375* |

Description

Product Overview

Inside the building materials line's cooling & quenching stage, a quality manager relies on the NPBD-110-1-1/2-316 to deliver consistent spray coverage that ensures even temperature control. Constructed from 316L stainless steel, this nozzle withstands corrosive environments commonly encountered during processing. The precision hollow cone spray pattern optimizes fluid distribution, reducing thermal stresses on materials. The operator monitors spray uniformity to maintain process stability and extend equipment longevity.

Applications

In cooling & quenching operations, the nozzle supports rapid heat dissipation to protect product integrity and improve cycle times. Its role in dust & pollution control helps minimize airborne particulates, contributing to safer work environments and regulatory compliance.

Industries

Sectors such as building materials, mining, and cement production select this nozzle for its corrosion resistance and reliable spray dynamics under harsh conditions. Manufacturing & assembly and roofing industries also benefit from its consistent performance in fluid handling and surface treatment tasks.