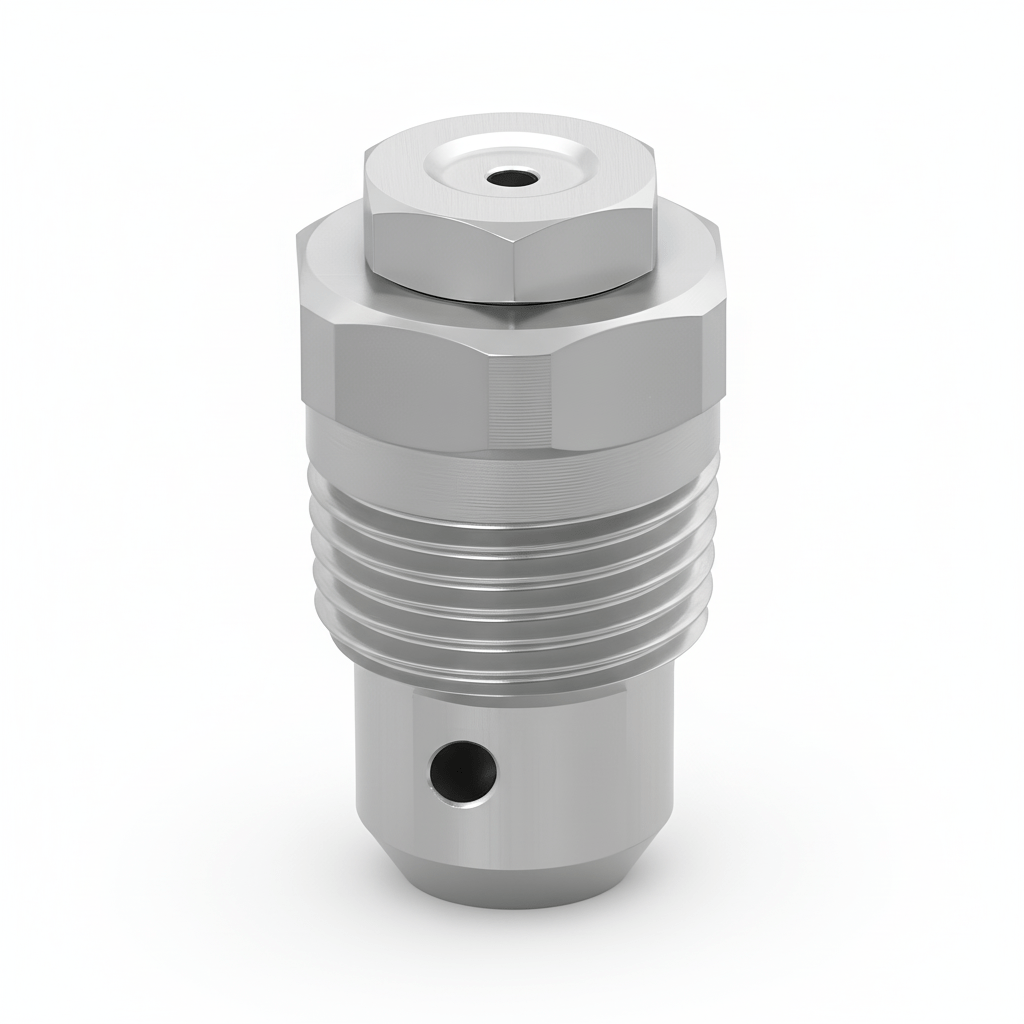

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBD |

| Capacity Size | 10 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4.4 |

| Orifice Diameter. Nom. (in) | 0.172 |

| Inlet Connection Size (in.) | 3/4 |

| Hex Size (mm) | 27 |

| Inlet Dia. Nom. (mm) | 5.2 |

| Inlet Dia. Nom. (in) | 0.203 |

Description

Product Overview

Inside the manufacturing & assembly line's car wash stage, a process engineer relies on the NPBD-10-3/4-316 to deliver consistent cleaning performance through its precision hollow cone spray pattern. Constructed from 316L stainless steel, the nozzle withstands corrosive environments while maintaining uniform distribution of water and detergents. Operators calibrate flow rates via the 3/4-inch inlet to optimize coverage and minimize water usage, ensuring process stability and repeatability during each wash cycle. This combination of material and design supports long operational life and reliable spray characteristics crucial to assembly line throughput.

Applications

The nozzle's hollow cone spray is particularly effective in cooling & quenching processes, where consistent fluid distribution prevents overheating and material deformation. Additionally, its uniform atomization plays a key role in dust & pollution control by efficiently suppressing airborne particulates in surrounding environments.

Industries

Building materials, mining, cement, roofing, and Energy sectors favor the NPBD-10-3/4-316 due to its resistance to harsh chemical exposure and ability to maintain spray integrity under demanding conditions. These industries depend on durable nozzles that deliver repeatable fluid application for processes ranging from surface treatment to environmental management.