Description

Specifications

Applications

Industries

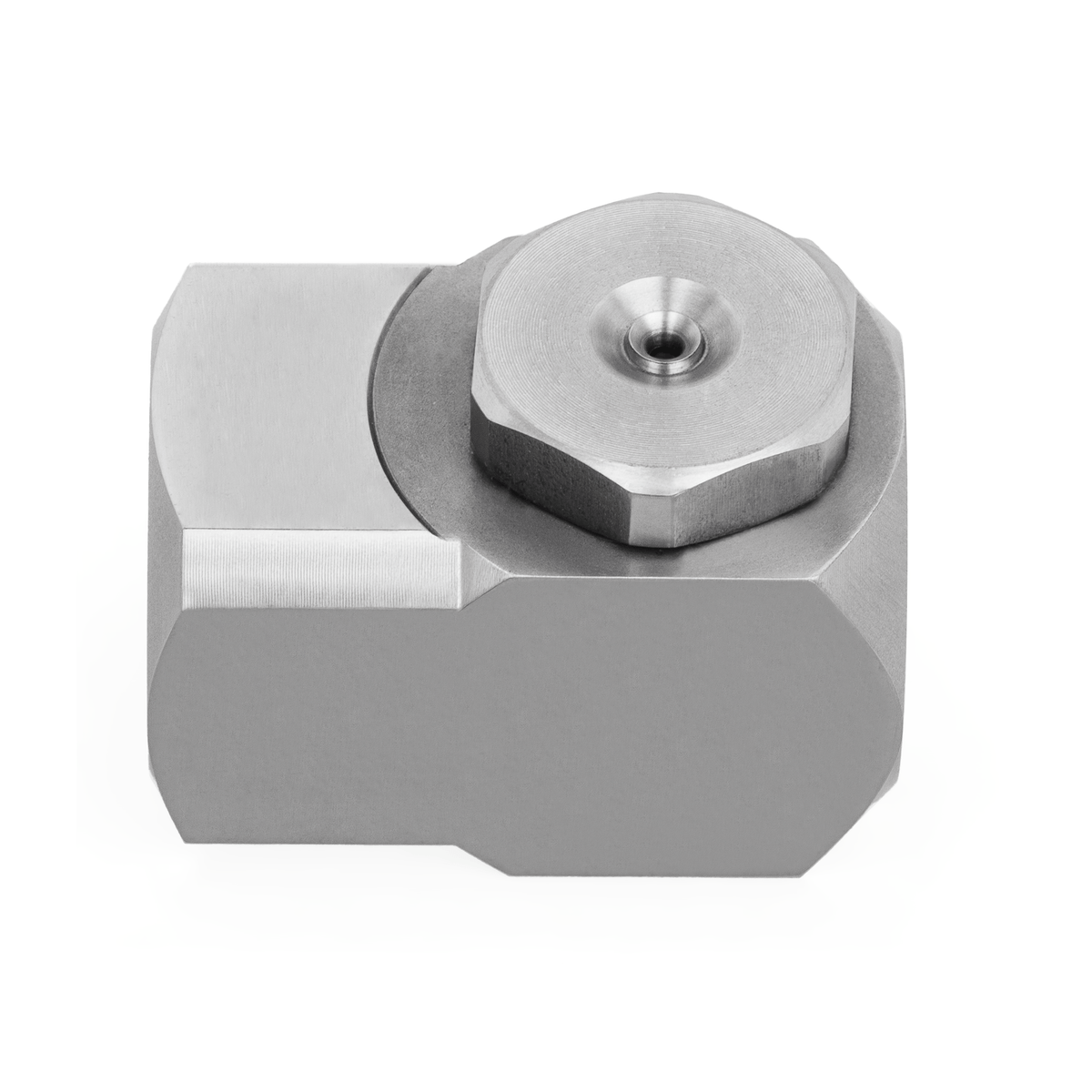

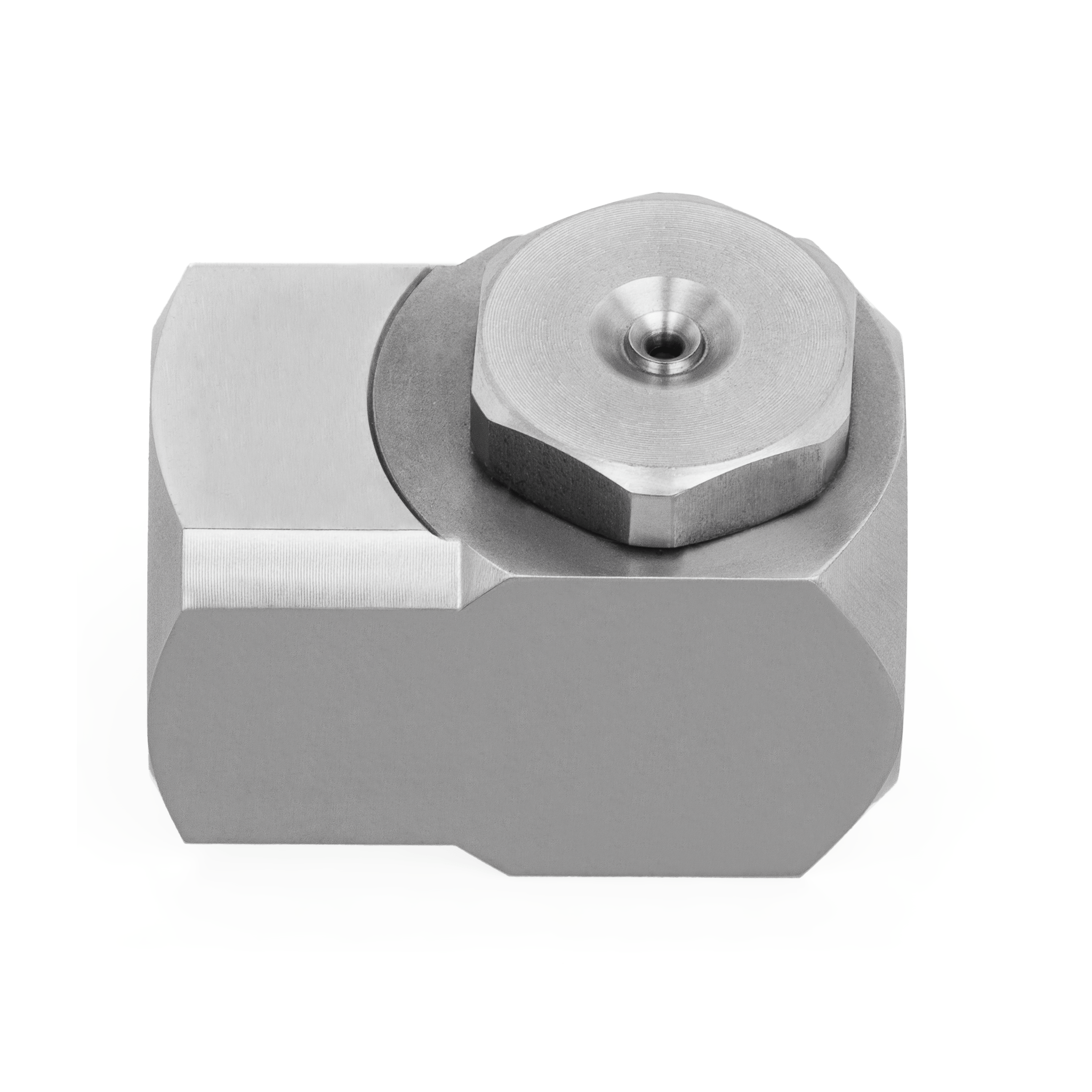

The NPAX-1-1W-1/8-316 hollow cone nozzle is manufactured from 316L stainless steel. Capacity Size: 1-1W. Inlet: 1/8" NPT Female. Nominal orifice diameter: 1.6 mm.

Please see the Specifications tab for detailed dimensions and configuration details.

Product Family

Hollow Cone

Product Series

NPAX

Capacity Size

1-1W

Inlet Connection Thread Type

NPT

Inlet Connection Gender

FEMALE (F)

Material Composition Filter

316L stainless steel

Orifice Diameter. Nom. (mm)

1.6

Orifice Diameter. Nom. (in)

0.063

Inlet Connection Size (in.)

1/8

Length (mm)

25.5

Length (in)

1.000

Inlet Dia. Nom. (in)

0.063

Max. Free Passage Dia. (mm)

1.6

Cooling & Quenching Dust & Pollution Control Humidification & Conditioning Specialty Applications

Automotive Building Materials Chemical Processing Energy Steel & Metals Breweries & Wineries Manufacturing & Assembly Meat & Poultry