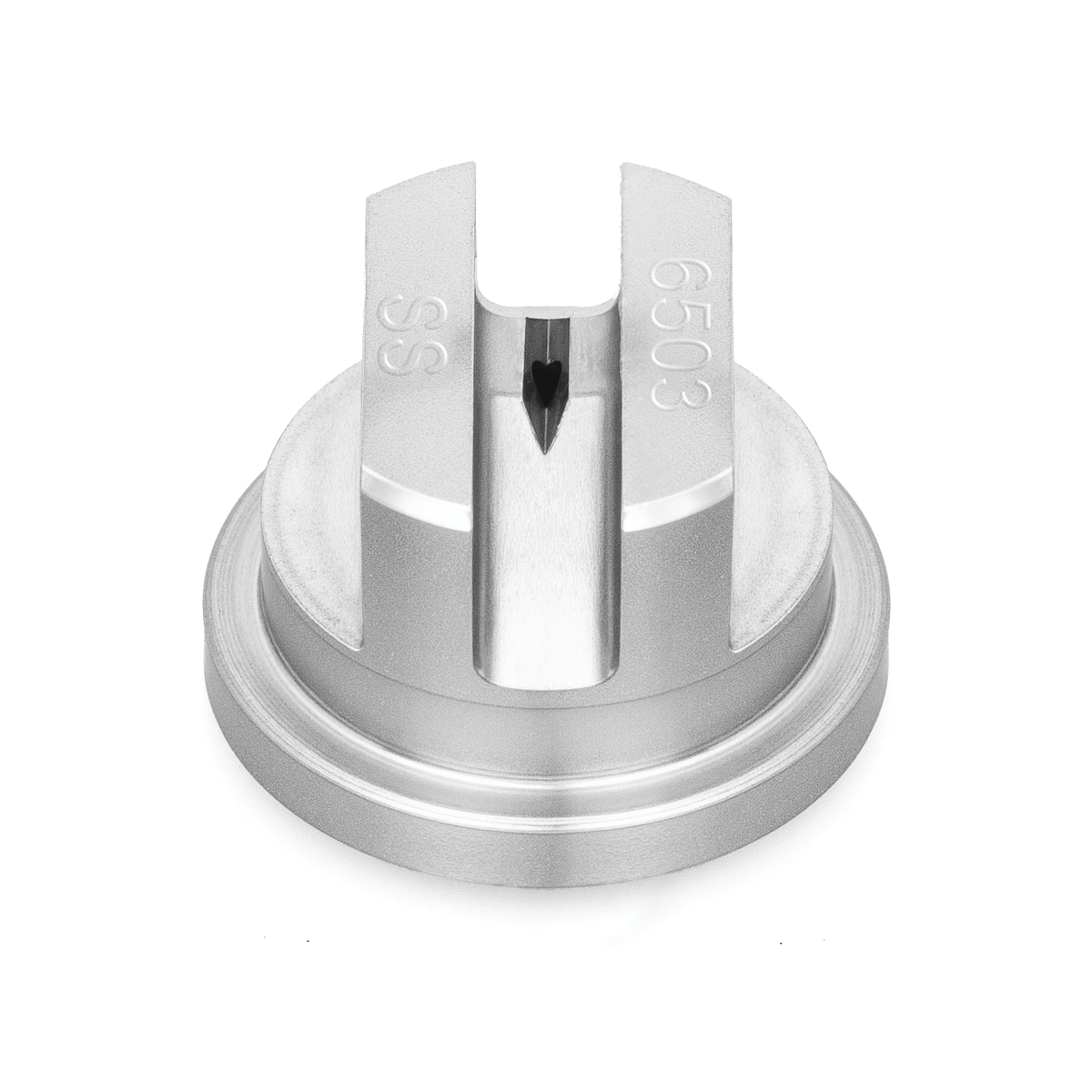

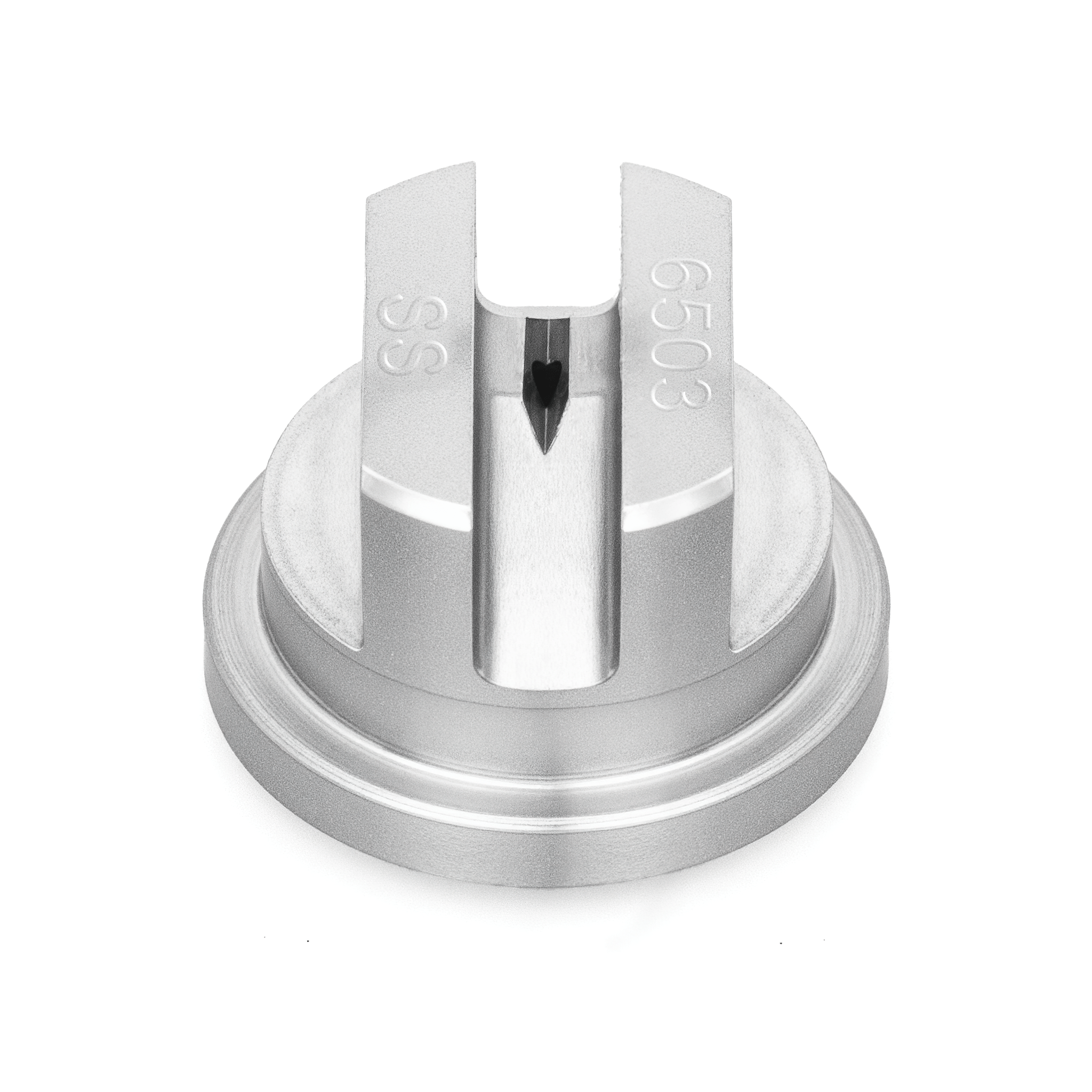

Product Parameters

| Product Family | ProJet 3X Modular Unit Assembly |

|---|---|

| Product Series | NP3U |

| Capacity Size | 10 |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 2.0 |

| Length (mm) | 48 |

| Hex Size (mm) | 20.6 |

| Spray Angle at Rated Pressure (PSI) | 65 |

| Diameter (in) | 0.079 |

Description

Product Overview

A process engineer in the breweries & wineries facility uses the NP3U-6510-SS during service & maintenance shops to ensure consistent spray coverage and reliable cleaning performance. Constructed from durable 303/304 stainless steel, the nozzle withstands corrosive environments common in brewing operations. Its 3x modular unit assembly design delivers a uniform spray pattern critical for thorough surface treatment, reducing downtime and maintenance costs. By integrating this nozzle, the engineer achieves controlled fluid distribution that supports operational efficiency.

Applications

In cleaning & washing processes, the NP3U-6510-SS provides precise fluid delivery that improves contaminant removal without damaging sensitive equipment. Additionally, this nozzle supports coating & surface treatment tasks by maintaining consistent spray patterns, which helps optimize product quality and finish uniformity across treated surfaces.

Industries

Sectors such as automotive, food & beverage, and steel & metals rely on the NP3U-6510-SS because of its corrosion resistance and spray consistency in challenging conditions. Building materials and mining industries also benefit from its robust construction, which sustains performance under abrasive and high-use scenarios.