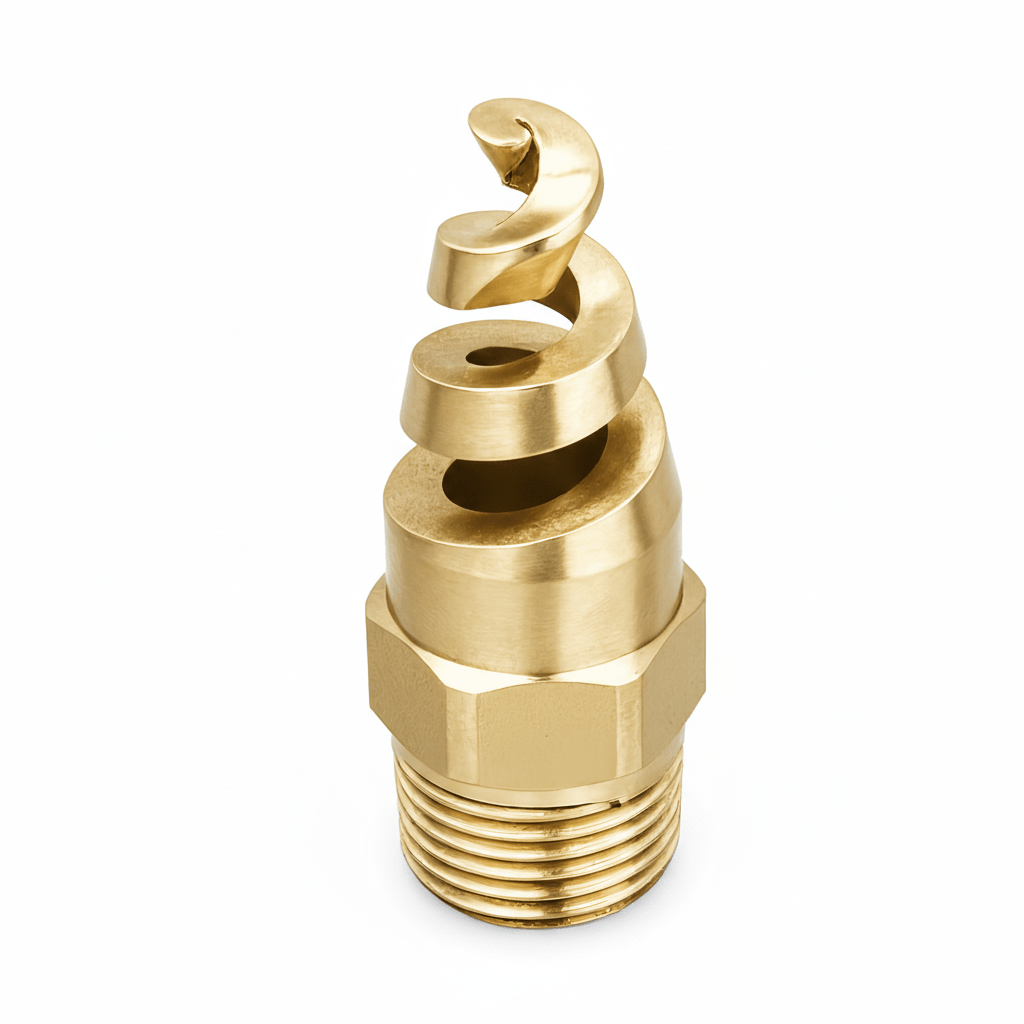

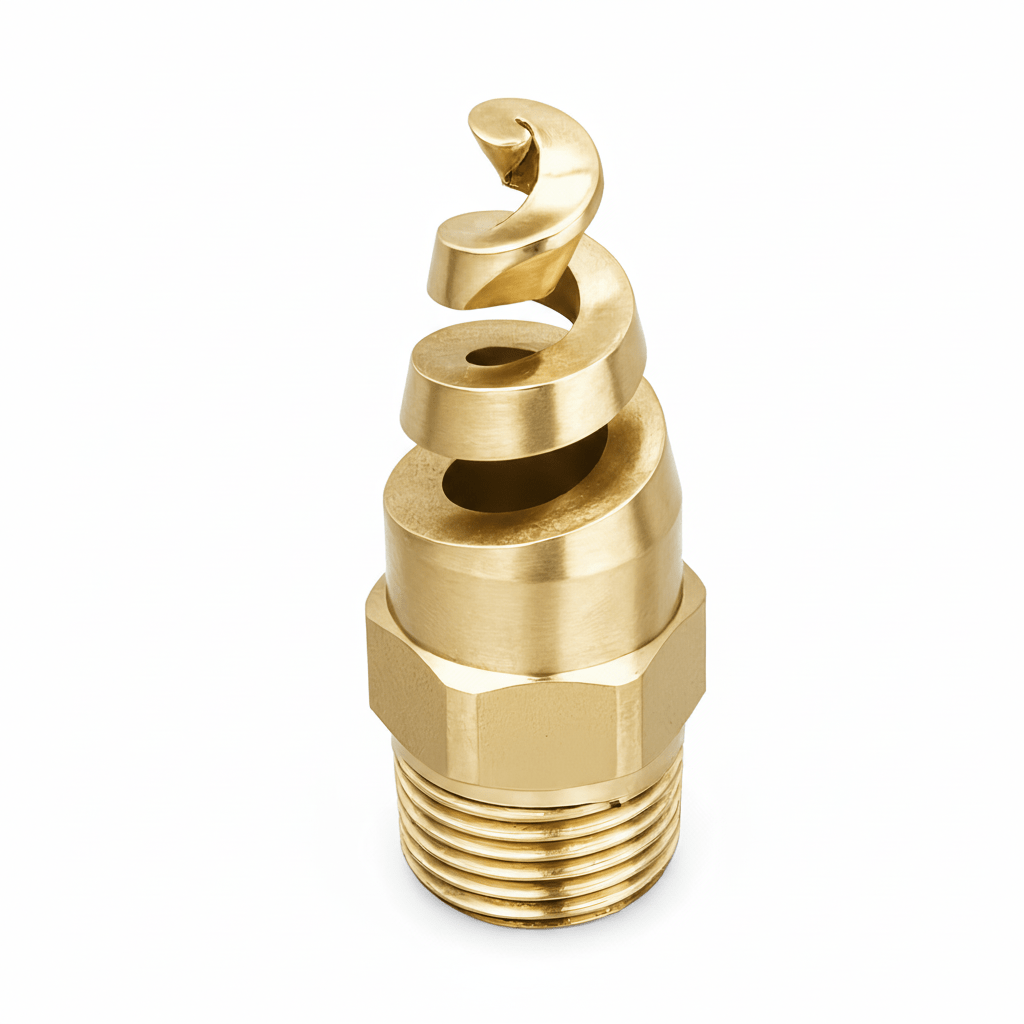

Product Parameters

| Product Family | Hollow Cone Spiral |

|---|---|

| Product Series | NPSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 15.9 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 92.1 |

| Hex Size (mm) | 34.9 |

| Spray Angle at Rated Pressure (PSI) | 90 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

During fire protection & safety on a steel & metals site, plant operators trust the NPSJ-90340-1 to deliver consistent and uniform spray coverage critical for preventing flare-ups and controlling temperature. The brass construction ensures corrosion resistance in harsh environments, while the precision hollow cone spiral design generates an even distribution of droplets. This reliable performance reduces downtime and maintenance costs by providing predictable fluid delivery under demanding conditions. Operators integrate the NPSJ-90340-1 into their safety systems to maintain optimal quenching and cooling processes across production lines.

Applications

In scenarios involving cleaning & washing, the nozzle's uniform spray pattern enhances contaminant removal efficiency, directly improving equipment uptime. Additionally, its role in cooling & quenching helps protect critical components from thermal damage, supporting longer operational cycles and reducing wear.

Industries

Sectors such as building materials, chemical processing, and steel & metals rely on the nozzle for its durability and spray consistency in corrosive or abrasive environments. Energy, mining, and manufacturing & assembly operations also benefit from the nozzle's ability to maintain performance during dust & pollution control and specialty applications, aligning with their strict process requirements.