Product Parameters

| Product Family | Adjustable |

|---|---|

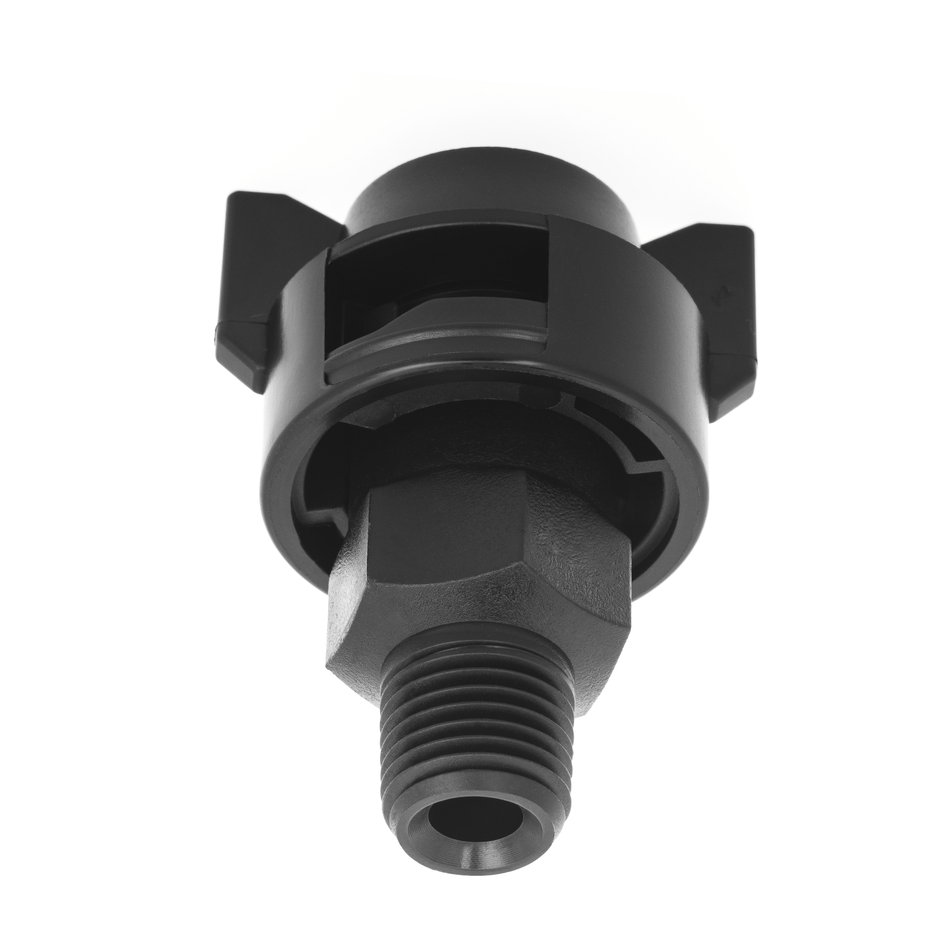

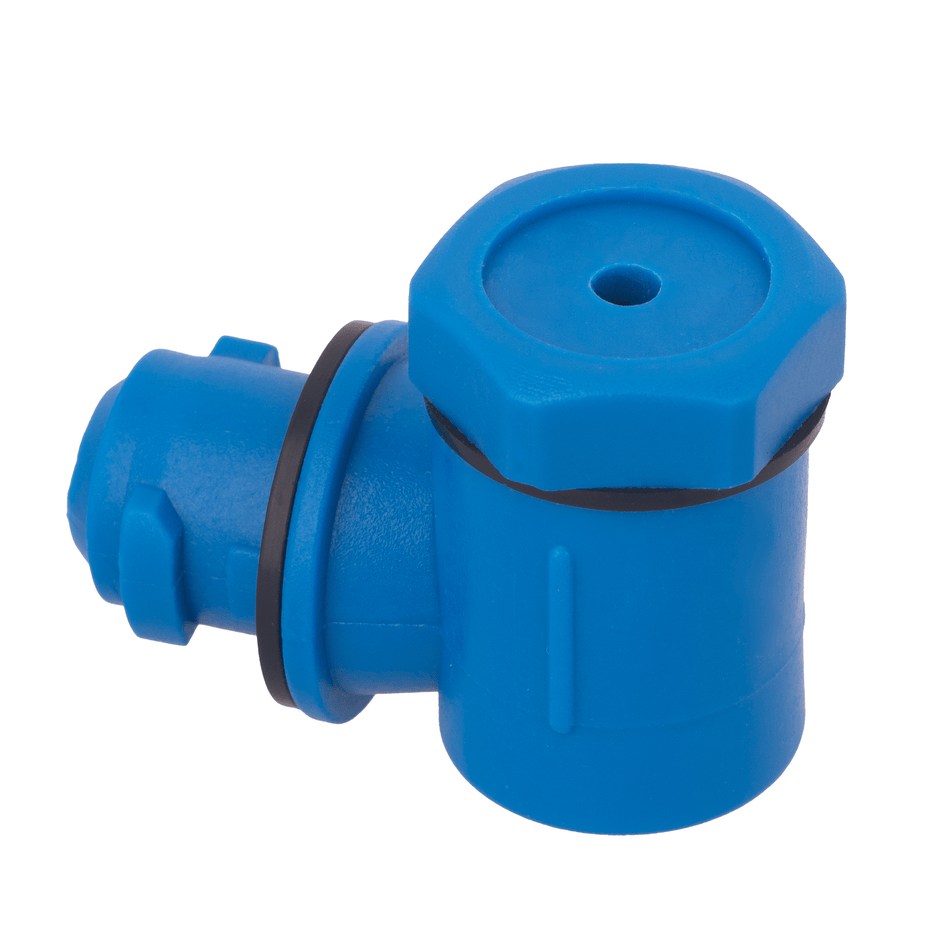

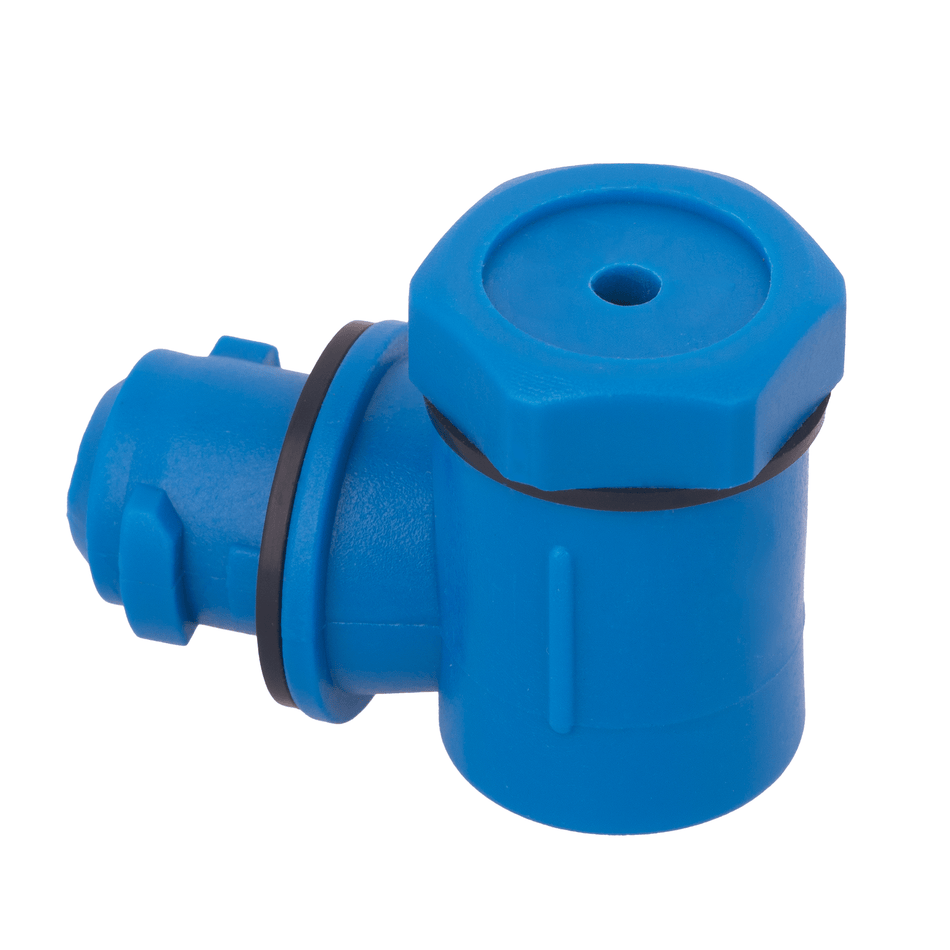

| Product Series | NPQH |

| Capacity Size | 3.5 |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 1.6 |

| Max. Free Passage Dia. (mm) | 1.3 |

Description

Product Overview

A process engineer in the breweries & wineries facility uses the NPQH-3.5-PP during disinfection & sanitation to ensure thorough coverage of all surfaces within fermentation tanks. The nozzle's polypropylene construction resists corrosion from cleaning agents, while its precision adjustable feature allows fine-tuning of the spray pattern to optimize fluid distribution. This adjustment helps maintain consistent droplet size and uniform coverage, reducing chemical waste and improving sanitation efficacy. Monitoring flow rates and spray angles confirms that the cleaning process meets strict hygiene standards.

Applications

Cleaning & washing processes benefit from the controlled spray delivered by the NPQH-3.5-PP, as it facilitates efficient removal of residues without damaging equipment surfaces. Additionally, its role in coating & surface treatment supports the application of protective layers that extend the lifespan of machinery parts in demanding operational environments.

Industries

Sectors such as building materials, food & beverage, and steel & metals rely on this nozzle for its ability to withstand harsh chemicals and maintain stable spray patterns. Manufacturing & assembly plants and meat & poultry operations incorporate the NPQH-3.5-PP to enhance cleaning and sanitation routines, ensuring compliance with industry regulations and maintaining product quality.