Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPK |

| Capacity Size | 210 |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 3/4 |

| Length (mm) | 65.1 |

| Length (in) | 2.563 |

| Hex Size (mm) | 38.1 |

| Hex Size (in) | 1-1/2 |

| Equivalent Orifice Diameter (in) | 0.484 |

| Equivalent Orifice Diameter (mm) | 12.3 |

Description

Product Overview

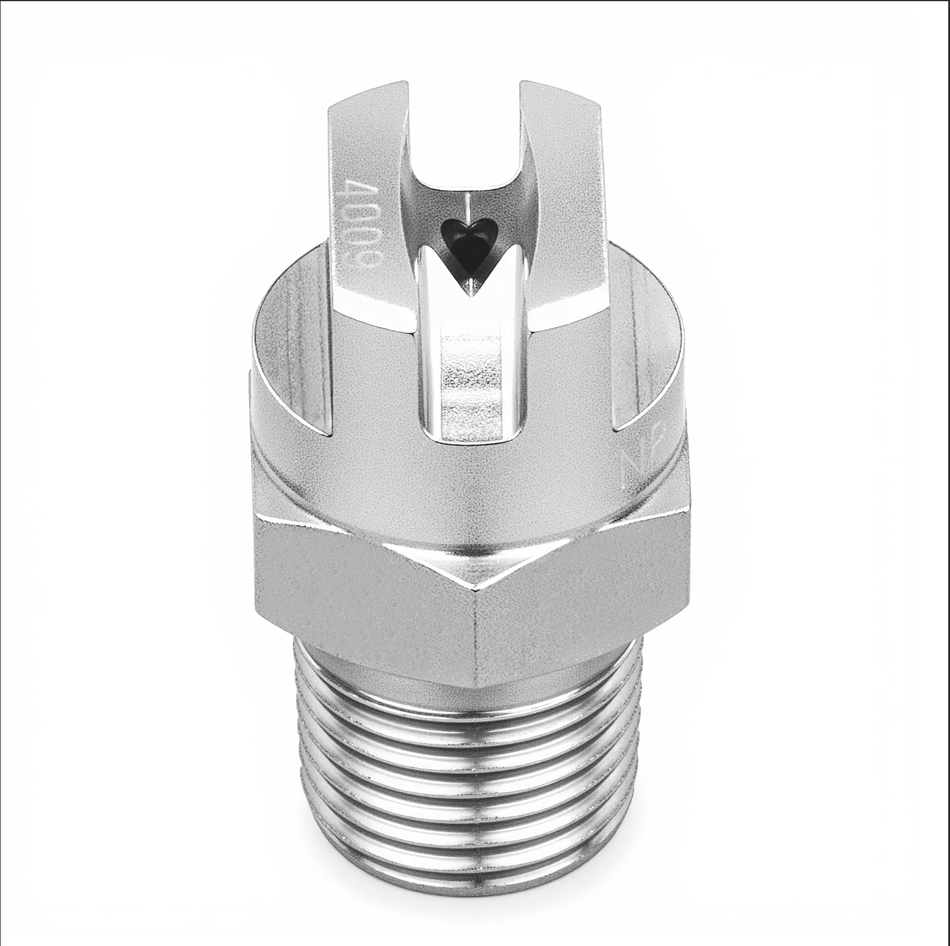

When meat & poultry crews manage coating & surface treatment, the NPK-210-3/4-316 lets each process engineer control coverage with a consistent flat spray pattern that ensures uniform application. Constructed from 316L stainless steel, the nozzle withstands corrosion from cleaning agents and product residues. Operators install the nozzle onto standard 3/4-inch inlets, allowing integration into existing spray systems while maintaining flow rates critical for process stability. The NPK-210-3/4-316 delivers precise distribution, reducing material waste and improving surface finish quality.

Applications

In cleaning & washing operations, the nozzle's uniform spray contributes to effective removal of contaminants without excessive water usage, supporting faster cycle times. It also plays a role in drying & blow-off stages by providing a consistent air or liquid curtain that aids in residual moisture removal, thereby enhancing overall line efficiency.

Industries

This nozzle is favored in automotive, building materials, and food & beverage industries due to its corrosion resistance and adaptable spray pattern. Additionally, sectors like breweries & wineries and beverage bottling & packaging rely on the NPK-210-3/4-316 for its durability in environments requiring frequent sanitation and precise fluid control.