Product Parameters

| Product Family | Flat |

|---|---|

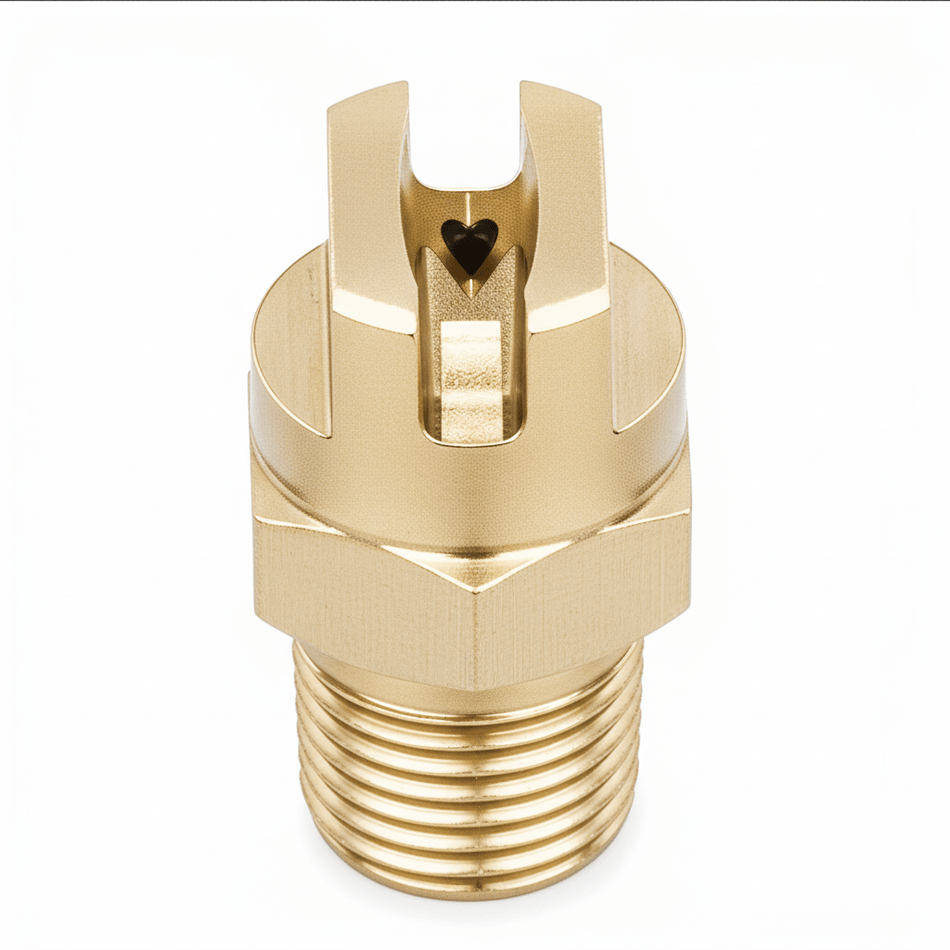

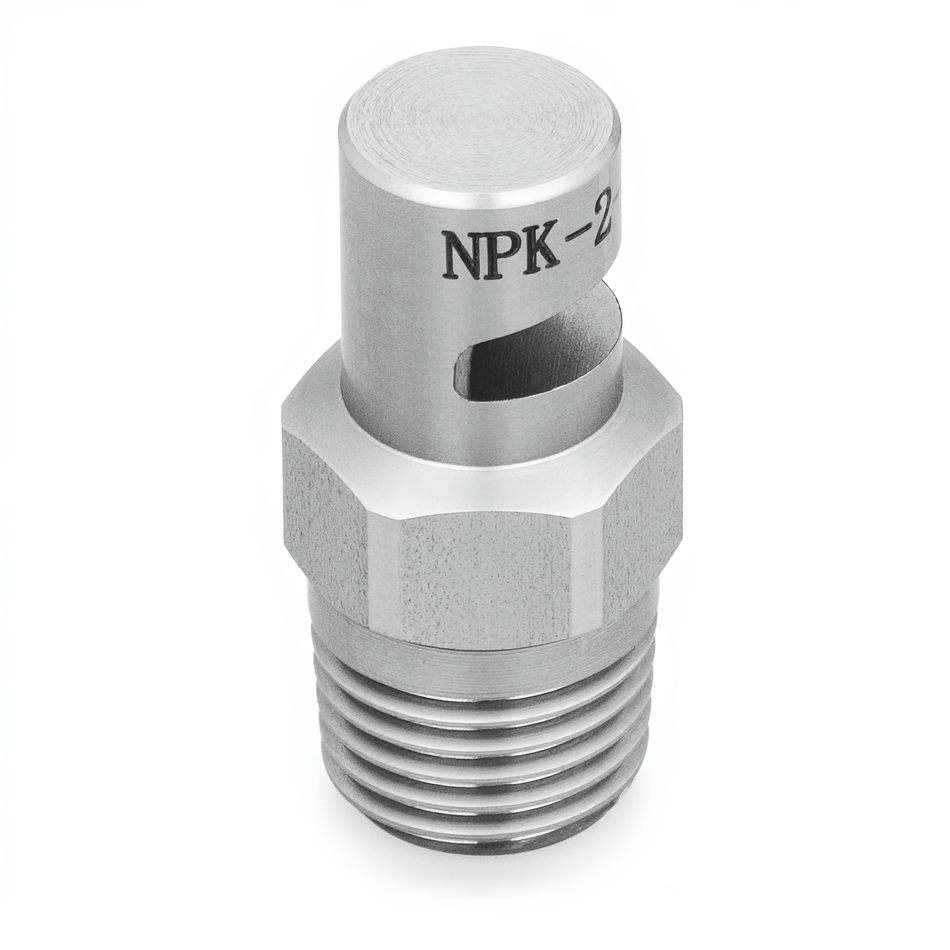

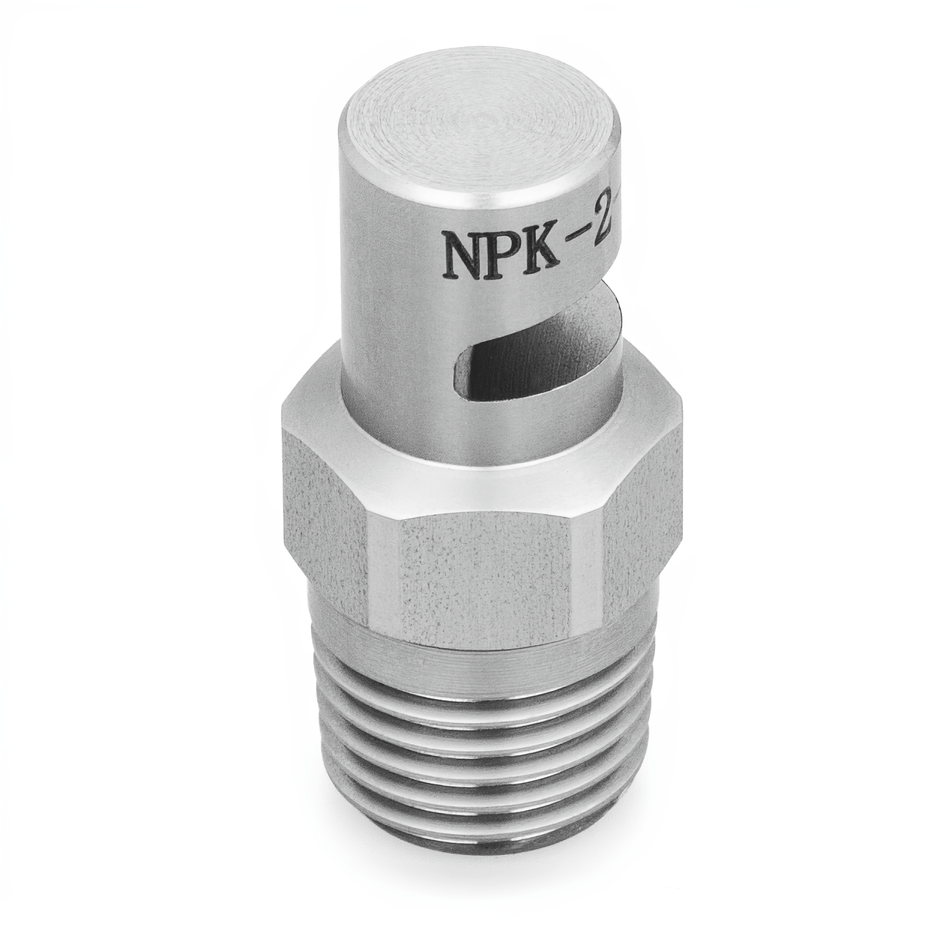

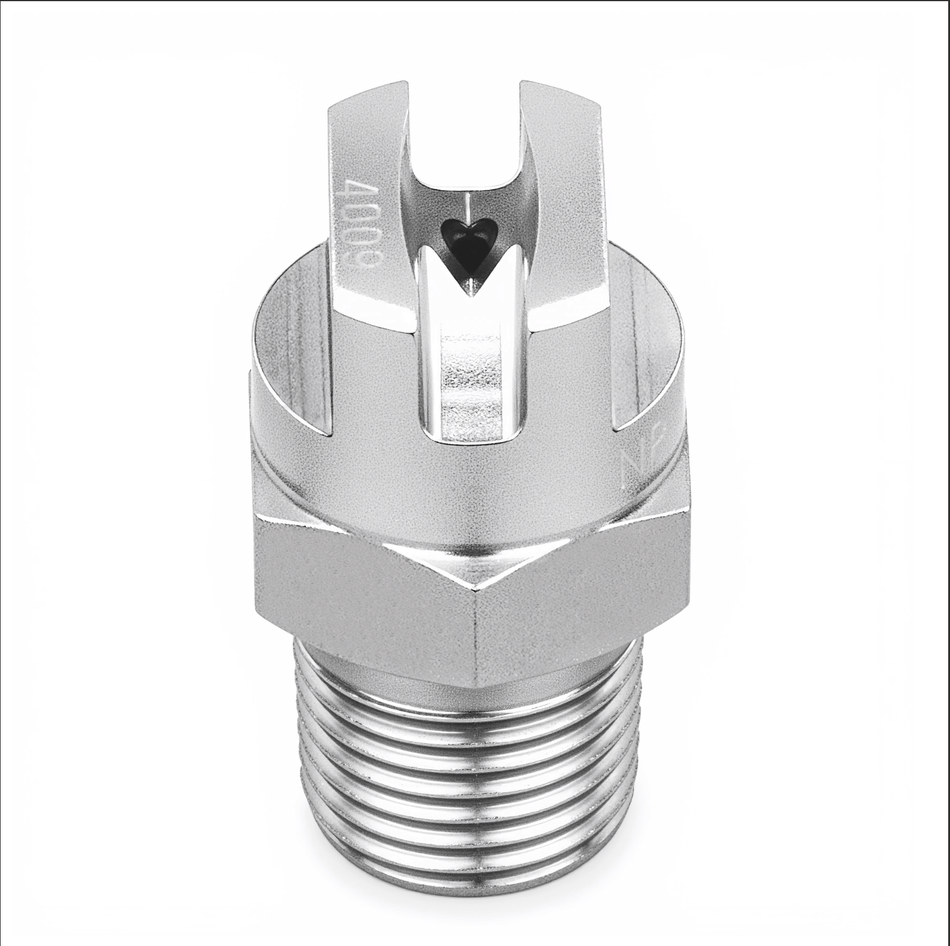

| Product Series | NPHVL |

| Capacity Size | 4 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.05 |

| Spray Angle at Rated Pressure (PSI) | 95 |

| Equivalent Orifice Diameter (mm) | 1.3 |

Description

Product Overview

Inside the bakery & confectionery line's dust & pollution control stage, a maintenance supervisor relies on the NPHVL-9504-1/8-316 to maintain consistent spray coverage for airborne particulate suppression. Constructed from 316L stainless steel, this nozzle resists corrosion in harsh cleaning environments while delivering a uniform flat spray pattern. When integrated into the system, it ensures reliable performance that reduces downtime and helps meet environmental compliance targets. The operator routinely inspects the nozzle to verify spray angle and flow rate stability during scheduled maintenance.

Applications

The NPHVL-9504-1/8-316 plays a critical role in cleaning & washing cycles where thorough surface treatment removes residues and contaminants without damaging sensitive materials. Its ability to provide consistent, controlled spray contributes to cooling & quenching processes by evenly distributing fluid over hot components, improving thermal management and process efficiency.

Industries

Sectors such as automotive, mining, and steel & metals utilize this nozzle for its durability under continuous use and resistance to harsh chemicals. Additionally, the food & beverage and beverage bottling & packaging industries favor this component due to its corrosion resistance and precise spray control, which support stringent hygiene and operational standards.