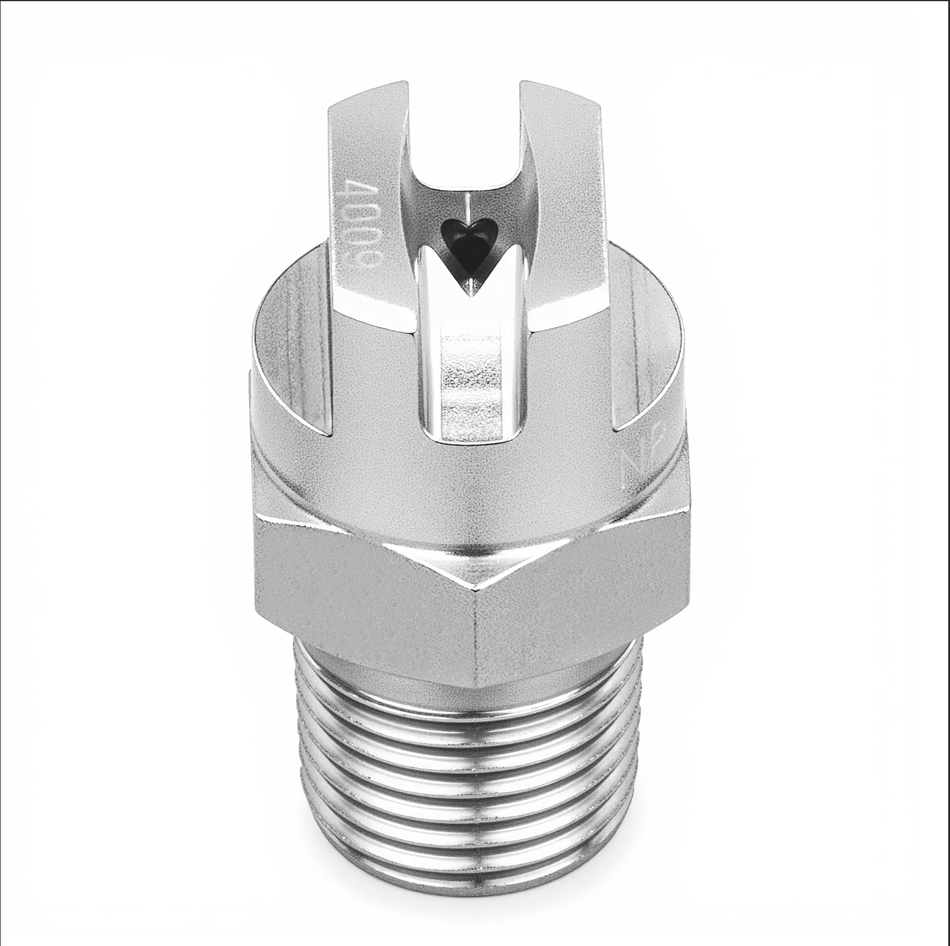

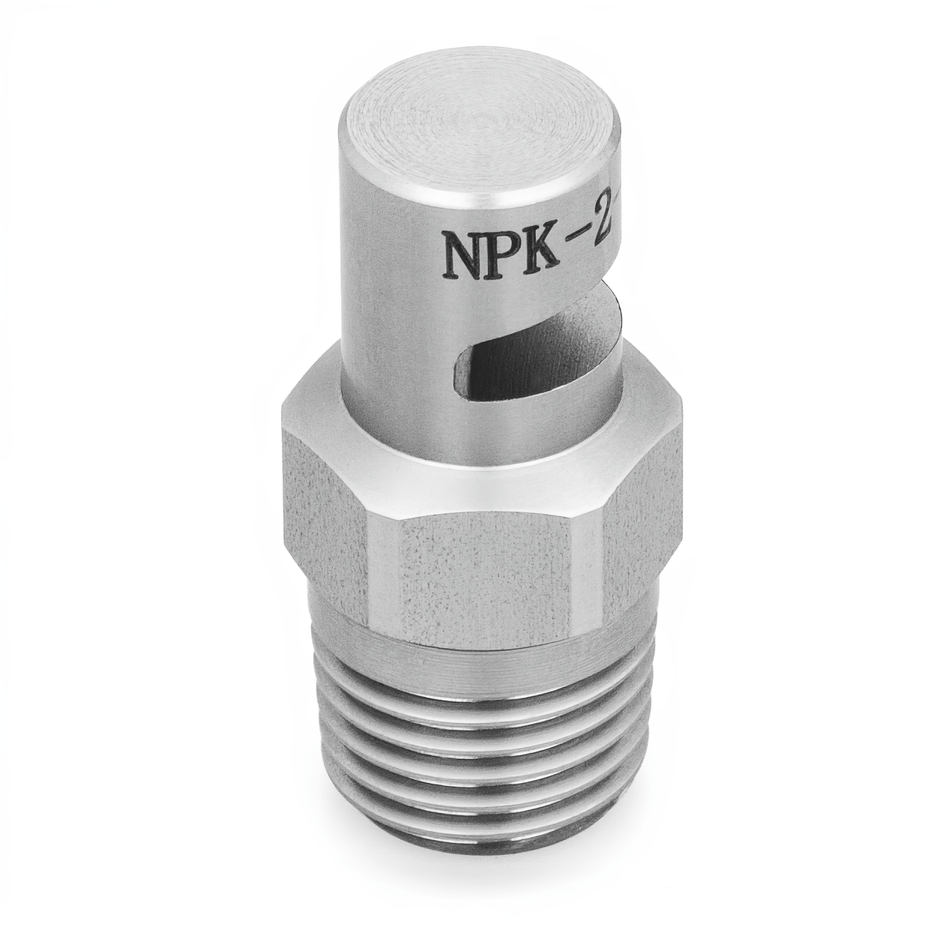

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 95 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

Inside the food & beverage line's dust & pollution control stage, a quality manager relies on the NPHVL-9503-1/4-316 to maintain consistent spray coverage and reduce particulate accumulation. Constructed from 316L stainless steel, this nozzle withstands corrosive environments commonly found in processing areas. The precision flat spray pattern ensures even distribution across conveyor belts and surfaces, improving cleanliness and minimizing contamination risks. Operators monitor spray uniformity and corrosion resistance to sustain operational efficiency and product safety.

Applications

In dust & pollution control, the nozzle delivers a uniform spray that captures airborne particles, reducing environmental contaminants and improving air quality around production zones. Additionally, its role in cleaning & washing applications helps maintain equipment hygiene, preventing cross-contamination and facilitating regulatory compliance.

Industries

This nozzle is preferred in industries such as automotive, steel & metals, and breweries & wineries, where corrosion resistance and consistent spray patterns are critical to managing harsh process conditions. Sectors like building materials, mining, and food & beverage benefit from the nozzle's durability and performance in both surface treatment and environmental control operations.