Product Parameters

| Product Family | Flat |

|---|---|

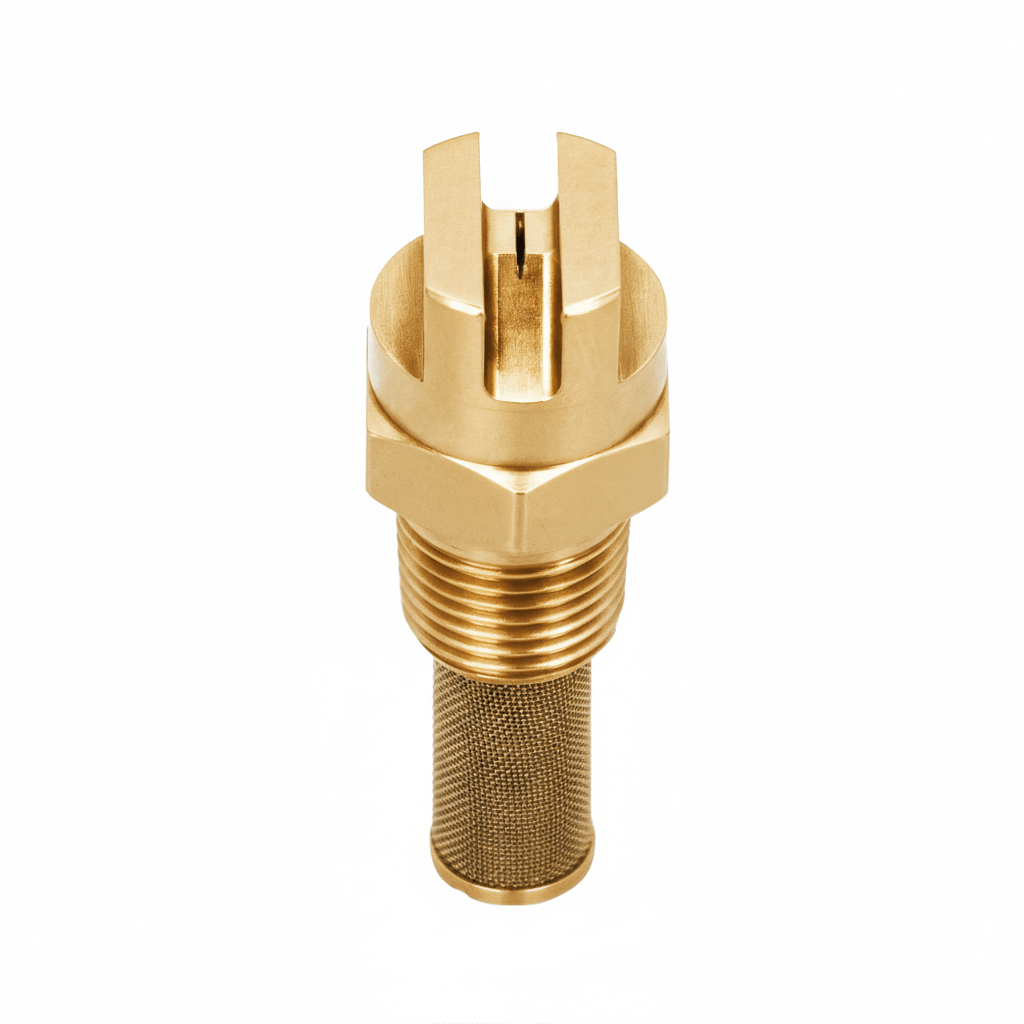

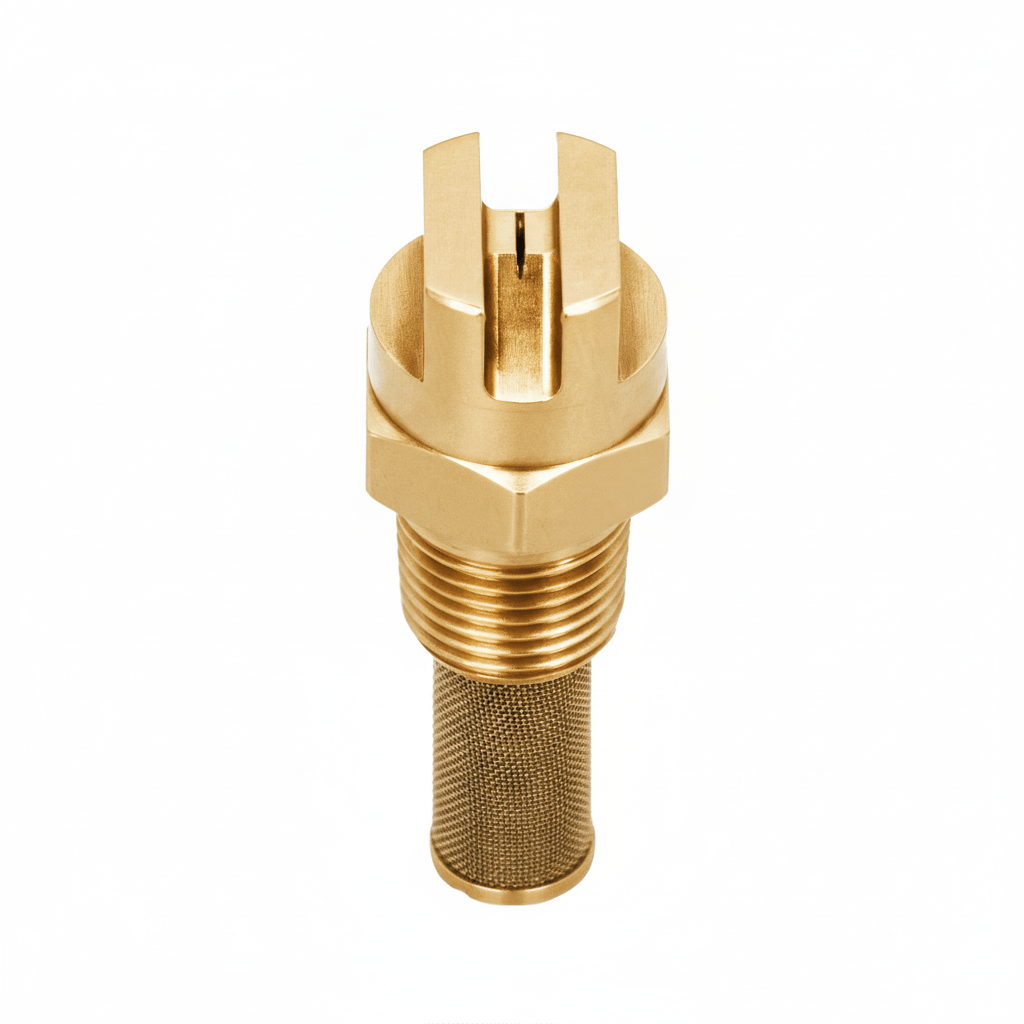

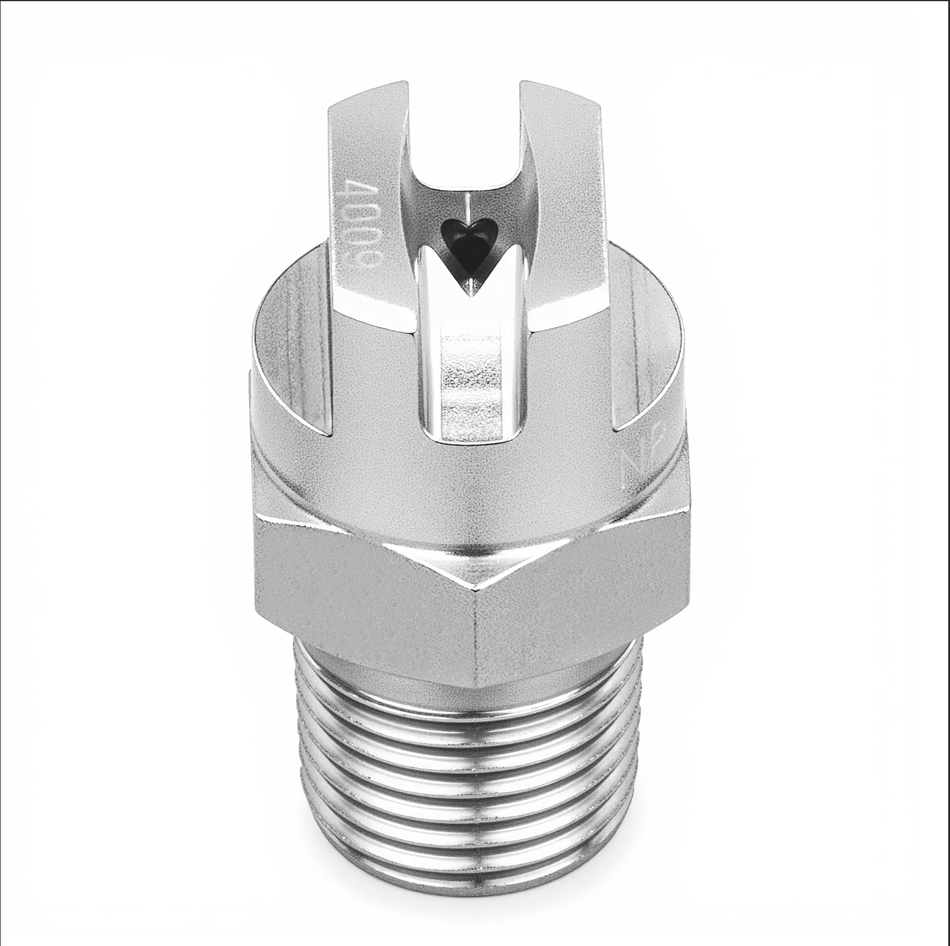

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Equivalent Orifice Diameter (in) | 0.043 |

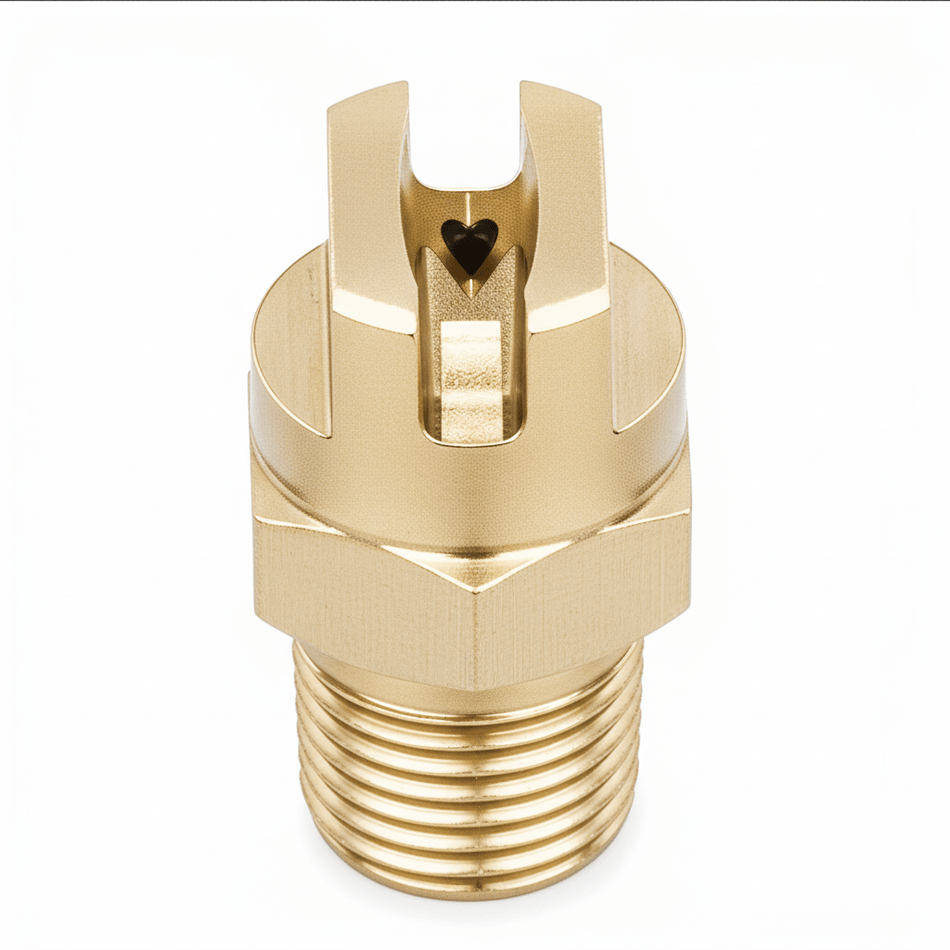

| Spray Angle at Rated Pressure (PSI) | 80 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

A utilities coordinator in the dairy facility uses the NPHVL-8003-1/4 during cooling & quenching to deliver a consistent flat spray that maintains precise temperature control on processing equipment. Constructed from brass, the nozzle resists corrosion from cleaning agents and prolonged moisture exposure, extending service intervals. The 1/4 inlet size allows easy integration into existing piping systems, enabling uniform coverage and reducing downtime associated with uneven cooling. As a result, operational efficiency improves through more reliable thermal management and decreased maintenance needs.

Applications

In cooling & quenching processes, the uniform spray pattern from the nozzle ensures rapid temperature reduction, preventing thermal damage and improving product consistency. Additionally, the nozzle supports cleaning & washing applications by providing controlled fluid distribution, which enhances surface treatment outcomes and reduces water usage.

Industries

The NPHVL-8003-1/4 is widely used across industries such as automotive, building materials, Energy, and food & beverage due to its durability and spray precision. Sectors like steel & metals, mining, and manufacturing & assembly rely on this nozzle to maintain equipment performance under harsh conditions, while dairy and beverage bottling & packaging benefit from its corrosion resistance and consistent fluid delivery.