Product Parameters

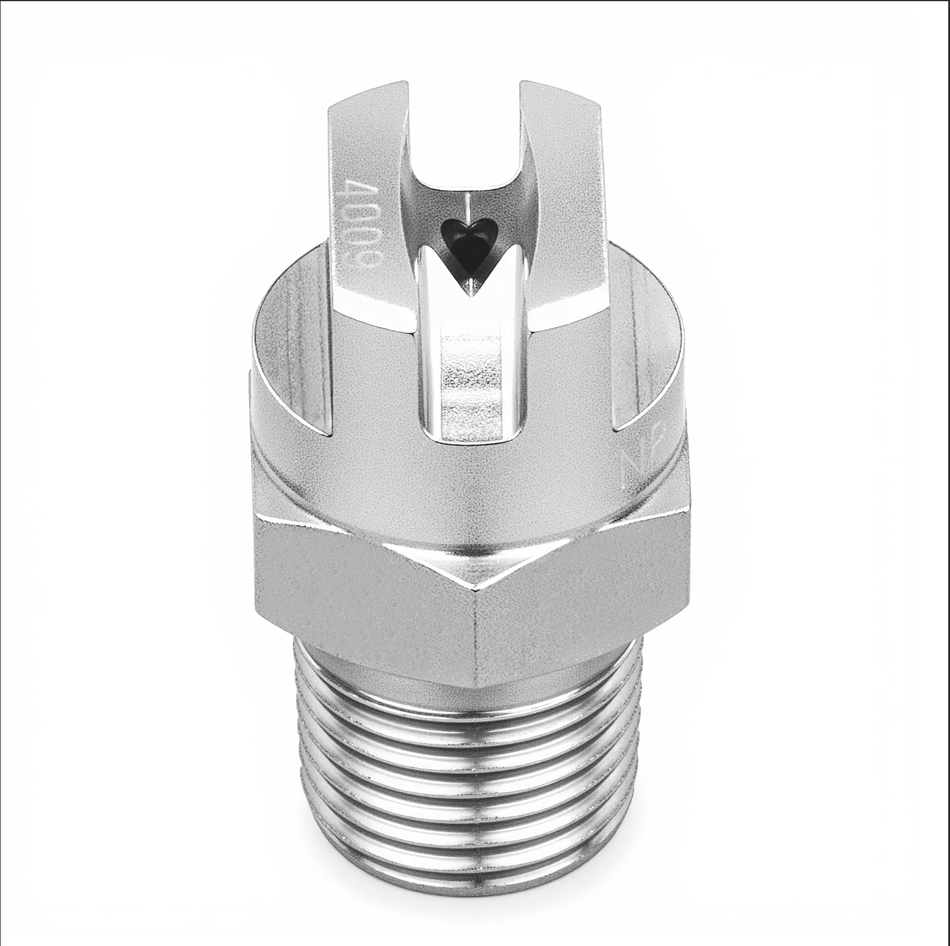

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 50 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

| Spray Angle at Rated Pressure (PSI) | 80 |

| Equivalent Orifice Diameter (mm) | 0.46 |

Description

Product Overview

During cooling & quenching on an engineered wood site, process engineers trust the NPHVL-800050-1/4-316 to deliver consistent coverage through its precision flat spray pattern. Constructed from 316L stainless steel, this nozzle withstands corrosive environments, ensuring longevity in demanding workflows. Operators integrate the nozzle with standard 1/4-inch inlets, achieving uniform liquid distribution that stabilizes thermal gradients and reduces material stress during quenching cycles. Precise control of spray parameters supports optimized process consistency and reduced downtime.

Applications

The uniform spray pattern of this nozzle enhances cleaning & washing operations, effectively removing residues without damaging sensitive surfaces. In cooling & quenching, it provides controlled temperature reduction that prevents warping and maintains mechanical integrity in composite materials.

Industries

Sectors such as automotive, steel & metals, and cement rely on this nozzle for its corrosion resistance and spray uniformity, which are critical in harsh process environments. Additionally, food & beverage and dairy industries benefit from its material compatibility and ease of maintenance, while energy and mining operations use it to support robust surface treatment and pollution control measures.