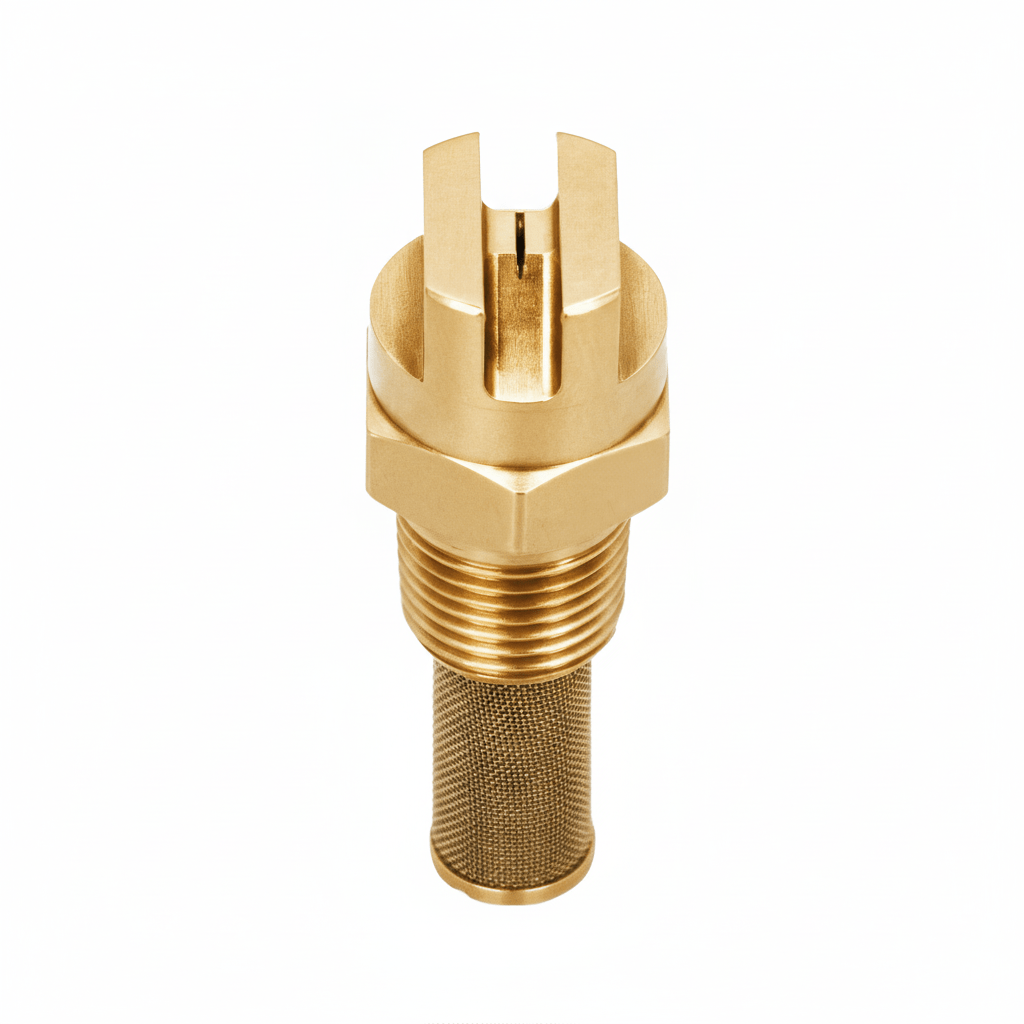

Product Parameters

| Product Family | Flat |

|---|---|

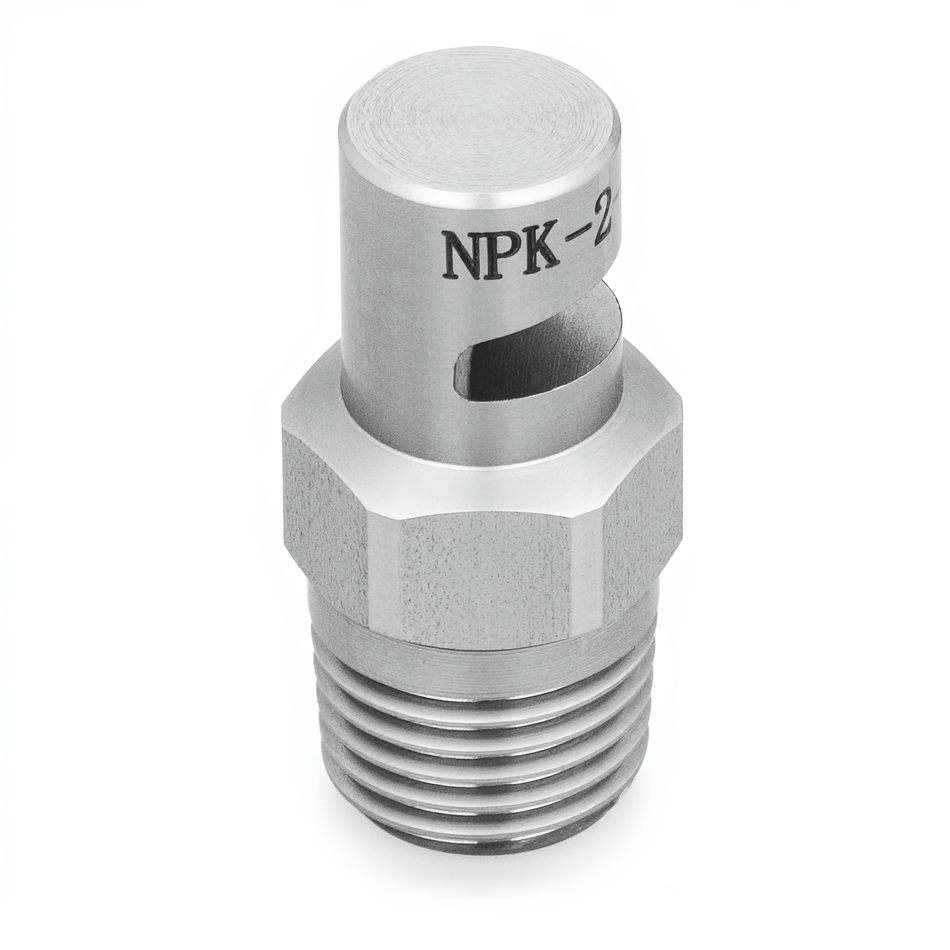

| Product Series | NPHVL |

| Capacity Size | 1 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

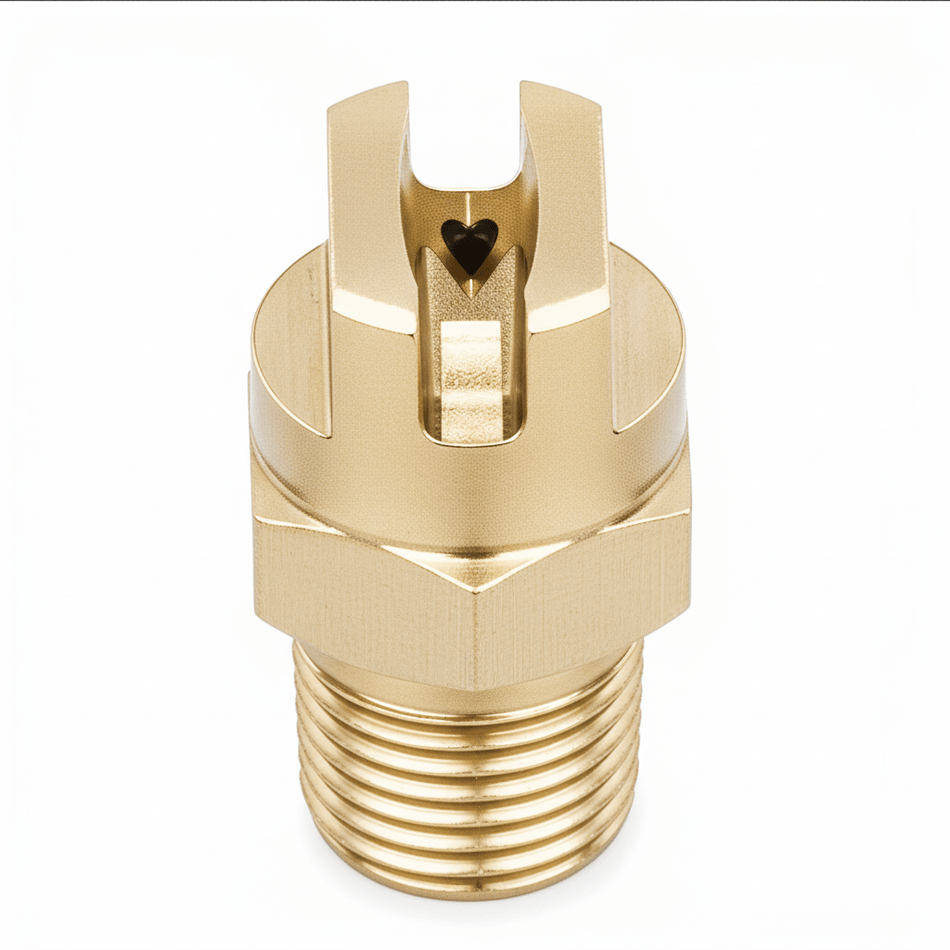

| Equivalent Orifice Diameter (in) | 0.026 |

| Spray Angle at Rated Pressure (PSI) | 50 |

| Equivalent Orifice Diameter (mm) | 0.66 |

Description

Product Overview

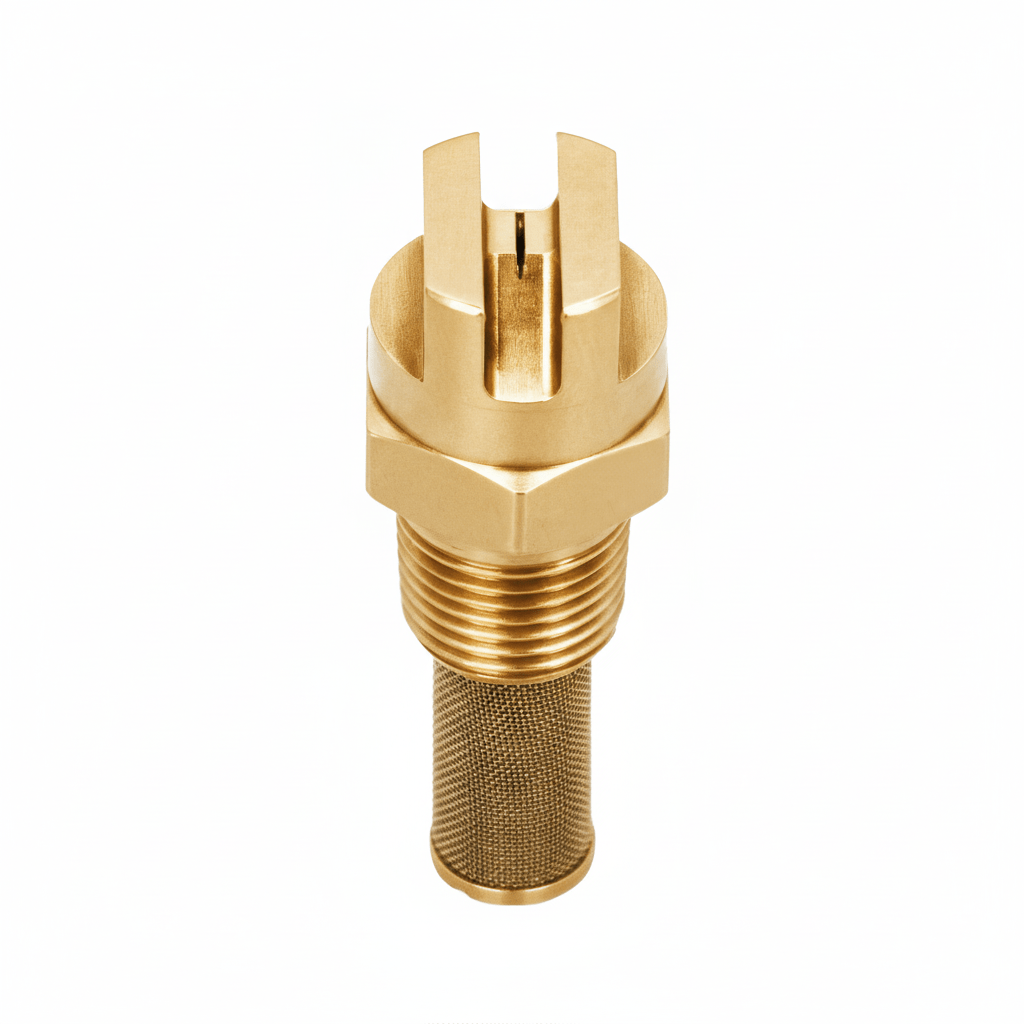

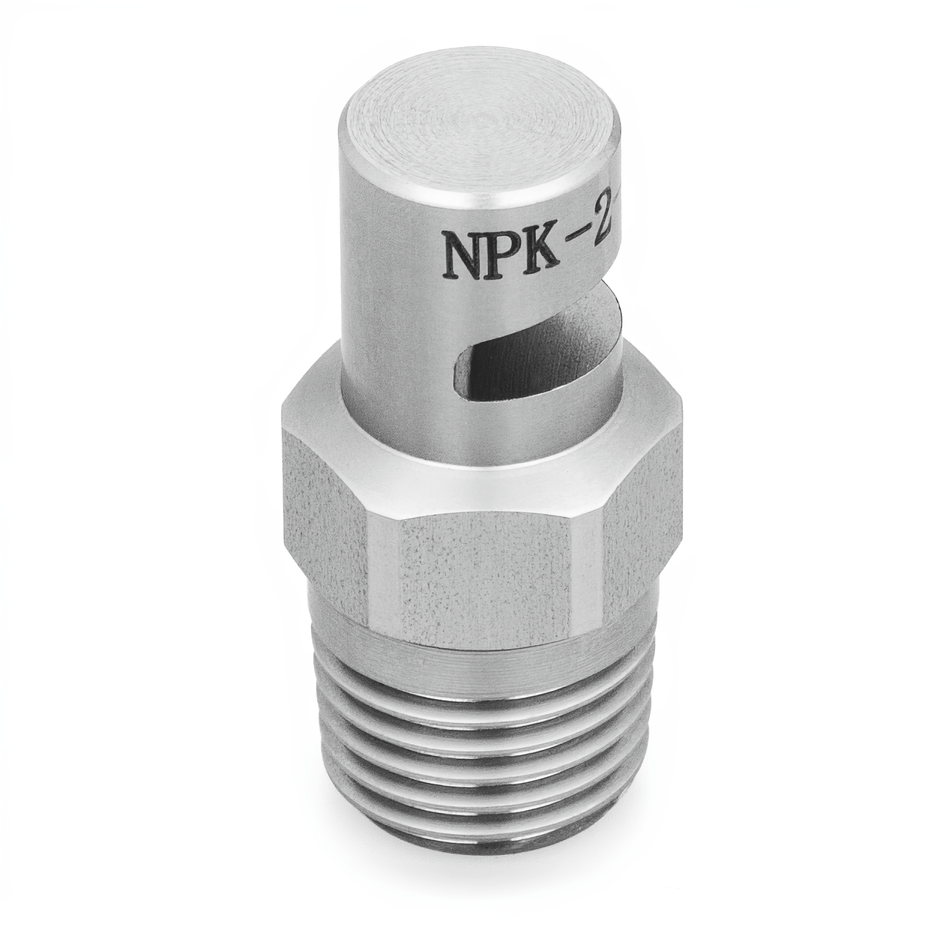

During cooling & quenching on a dairy site, process engineers trust the NPHVL-5001-1/8 to deliver consistent spray coverage with its precision flat brass design and 1/8-inch inlet. Operators integrate this nozzle into existing piping systems to achieve uniform fluid distribution, which helps maintain product quality and equipment integrity. The brass construction provides corrosion resistance, extending service intervals in harsh processing environments. Precise control of spray patterns reduces waste and supports regulatory compliance by minimizing overspray and runoff.

Applications

In cooling & quenching processes, the nozzle's uniform spray pattern ensures even temperature reduction, preserving product quality and equipment lifespan. Additionally, cleaning & washing tasks benefit from its reliable coverage, improving surface treatment readiness and reducing downtime.

Industries

The NPHVL-5001-1/8 is favored in industries such as automotive, food & beverage, manufacturing & assembly, and steel & metals due to its durability and consistent spray output. Sectors like mining, cement, and roofing also rely on this nozzle for applications requiring corrosion resistance and precise fluid handling under demanding conditions.