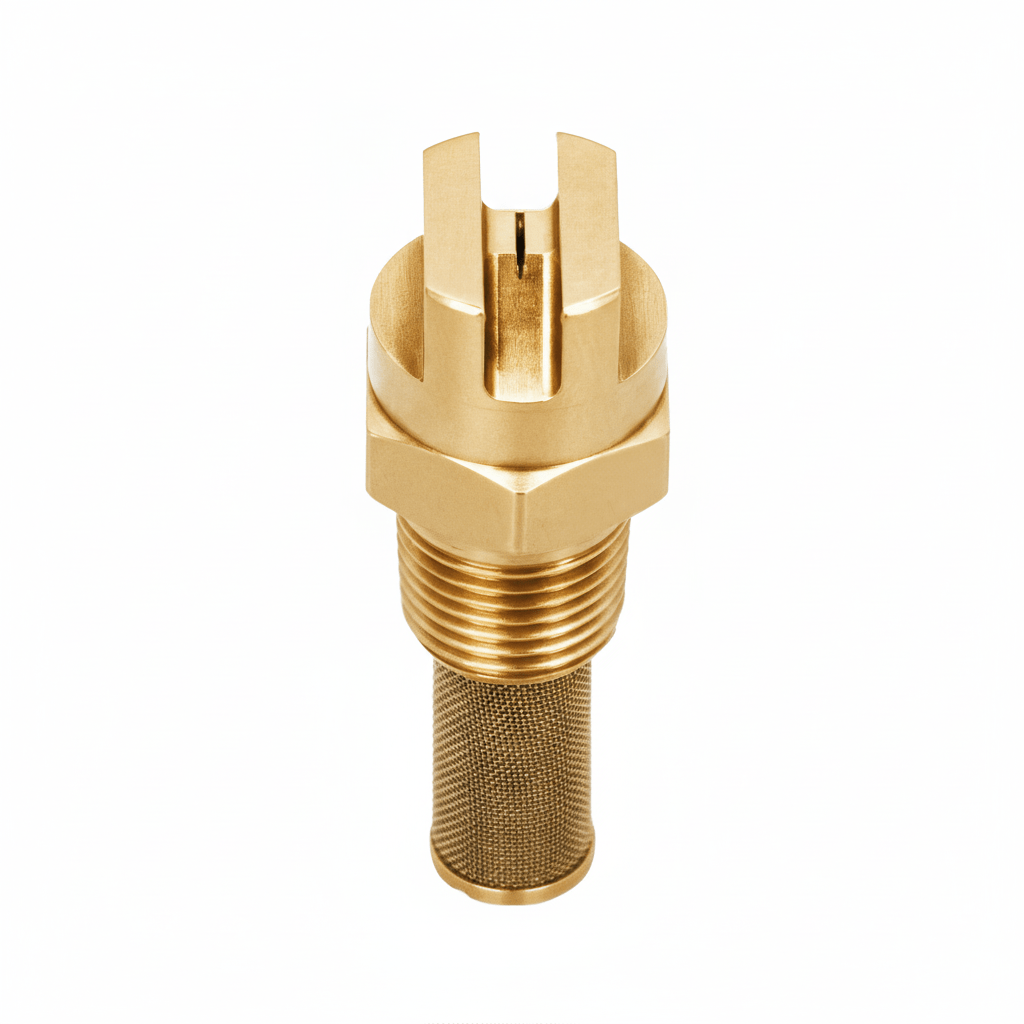

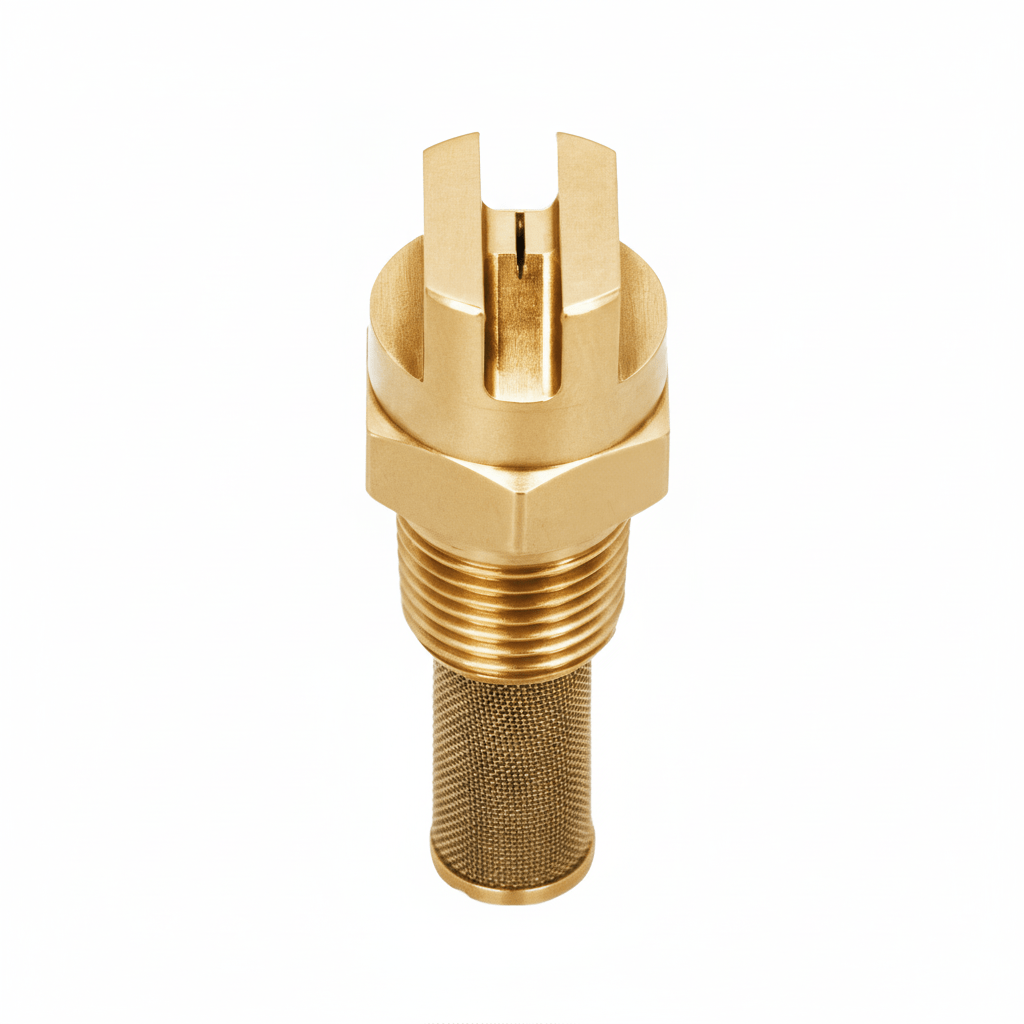

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 1 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/4 |

| Length (mm) | 38 |

| Length (in) | 1.250 |

| Hex Size (mm) | 14.3 |

| Hex Size (in) | 9/16 |

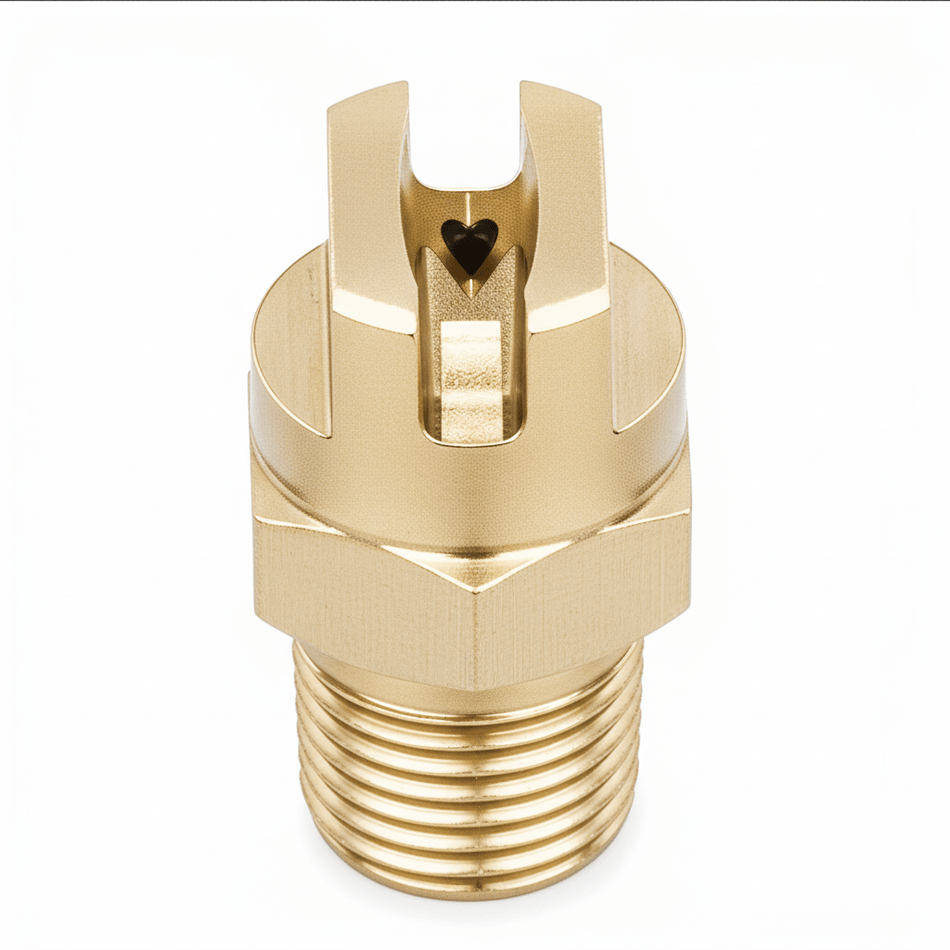

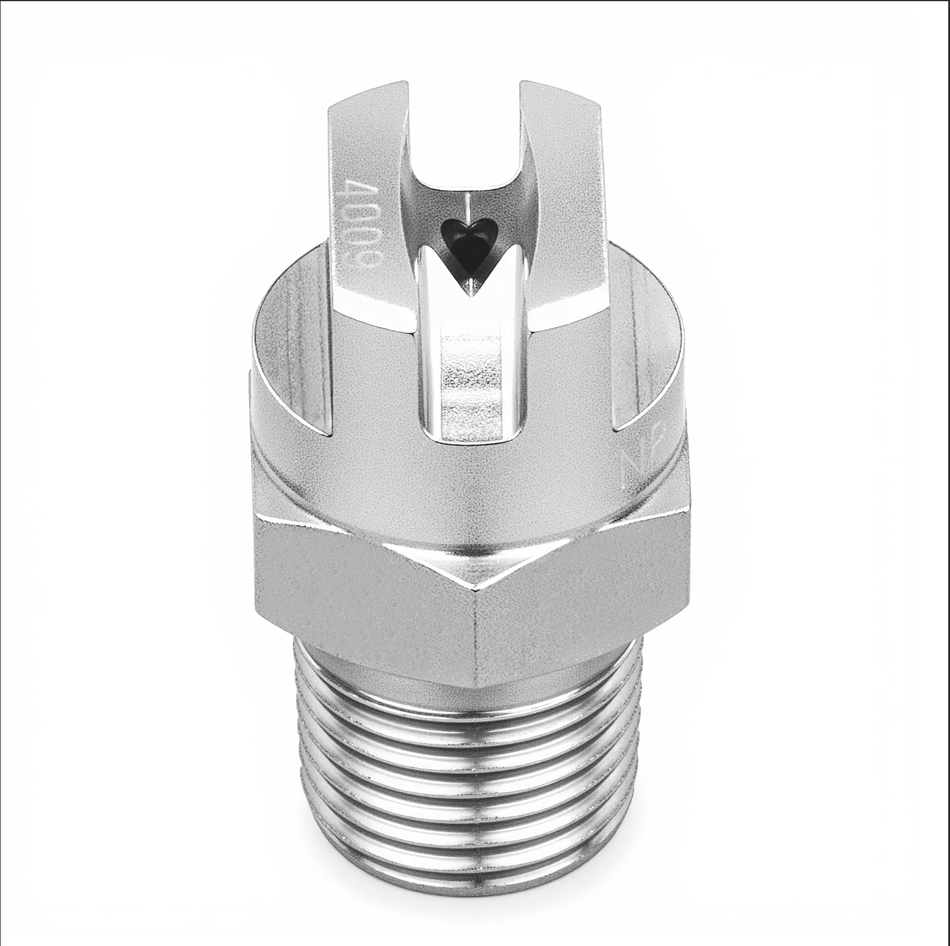

| Equivalent Orifice Diameter (in) | 0.026 |

| Spray Angle at Rated Pressure (PSI) | 50 |

| Equivalent Orifice Diameter (mm) | 0.66 |

Description

Product Overview

Inside the steel & metals line's cooling & quenching stage, a quality manager relies on the NPHVL-5001-1/4 to deliver consistent flat spray coverage that ensures even temperature reduction across metal surfaces. Constructed from brass, this nozzle resists corrosion in harsh environments while maintaining precise flow control through its 1/4-inch inlet connection. Operators value the uniform spray pattern for minimizing thermal stress and preventing warping during rapid cooling cycles. The NPHVL-5001-1/4 integrates smoothly into automated systems, supporting repeatable outcomes in demanding production conditions.

Applications

In cooling & quenching processes, the nozzle's flat spray pattern contributes to uniform heat extraction, which improves material integrity and cycle efficiency. It also plays a critical role in cleaning & washing operations by delivering controlled liquid distribution that reduces residue buildup and facilitates equipment maintenance.

Industries

This nozzle is commonly employed in automotive, food & beverage, and manufacturing & assembly settings where precision fluid delivery is essential for process reliability. Sectors like mining, engineered wood, and roofing also favor the NPHVL-5001-1/4 for its corrosion resistance and ability to maintain consistent spray patterns under varied operational demands.