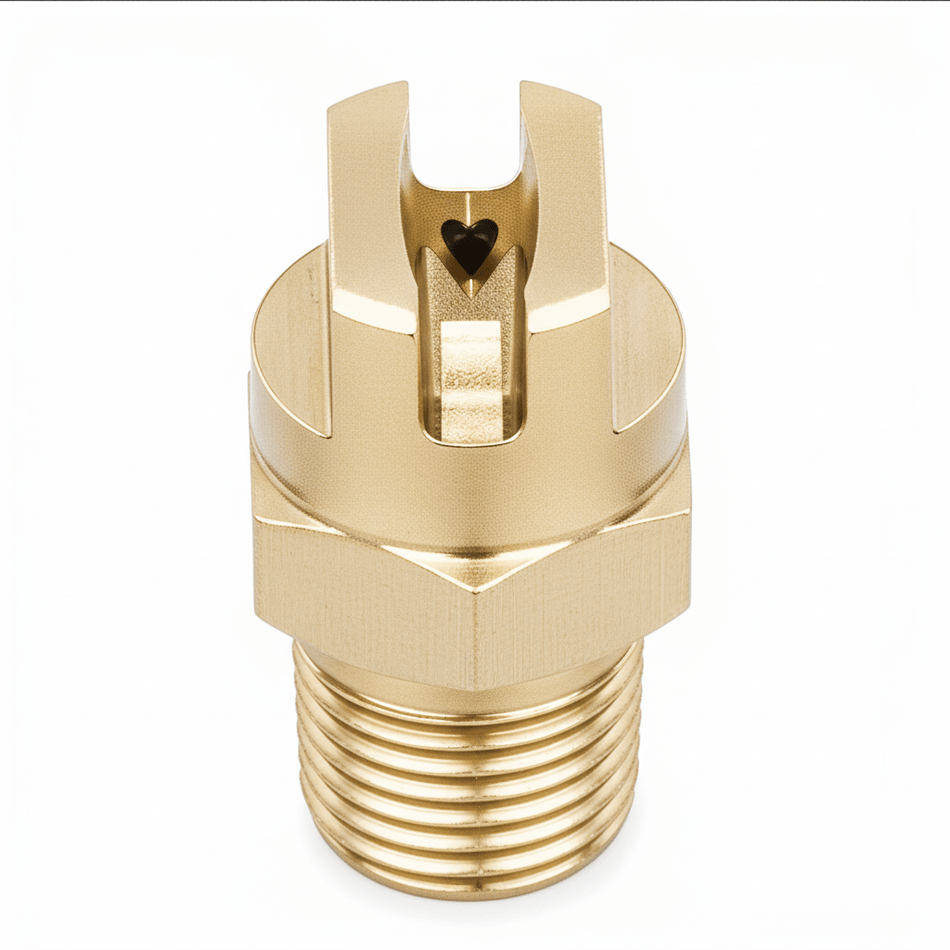

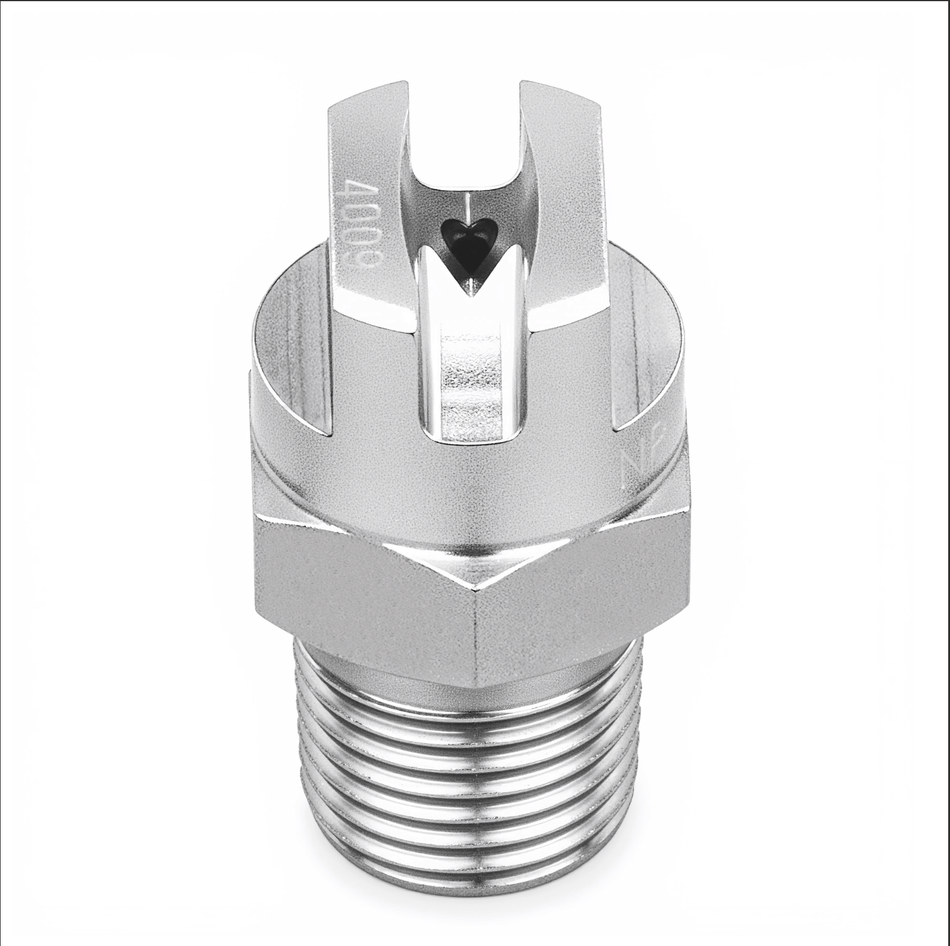

Product Parameters

| Product Family | Flat |

|---|---|

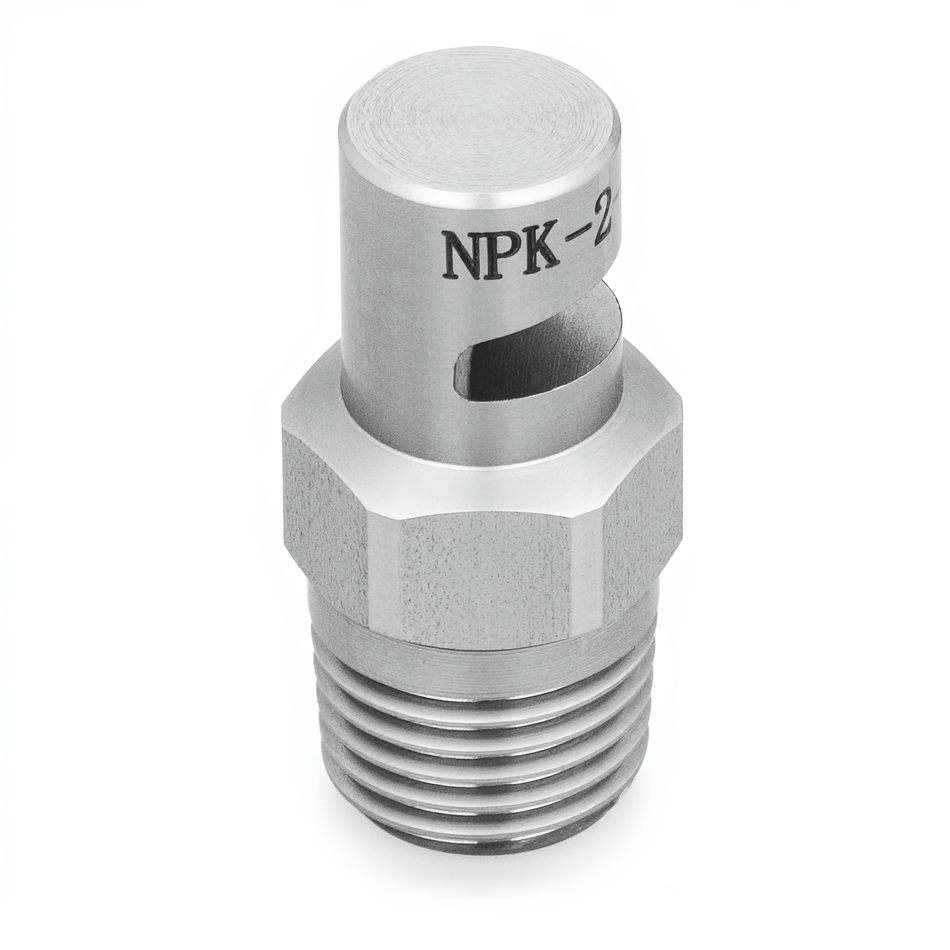

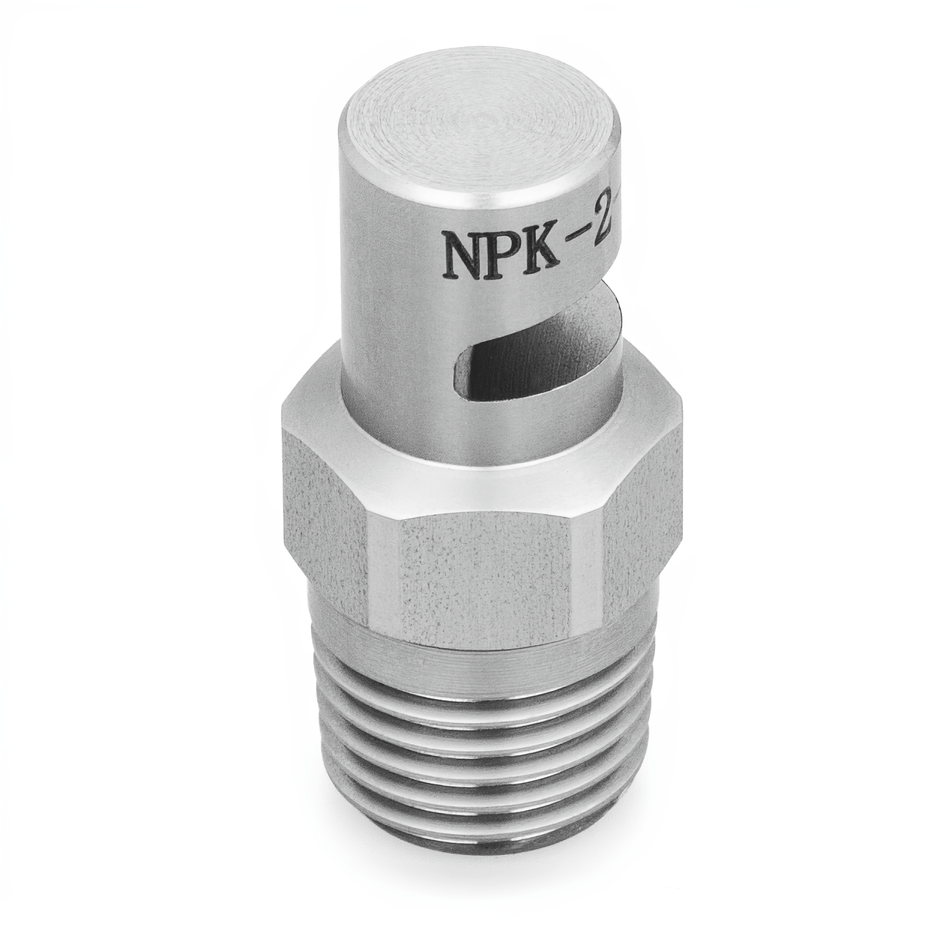

| Product Series | NPHVL |

| Capacity Size | 5 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 303/304 stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.056 |

| Spray Angle at Rated Pressure (PSI) | 40 |

| Equivalent Orifice Diameter (mm) | 1.4 |

Description

Product Overview

During cooling & quenching on a cement site, process engineers trust the NPHVL-4005-1/8-SS to deliver consistent flat spray coverage that enhances thermal management. Constructed from 303/304 stainless steel, the nozzle withstands harsh chemical exposure and abrasive conditions typical of industrial environments. Operators install the nozzle using the 1/8 inlet interface, ensuring a secure fit that minimizes downtime. The uniform spray pattern helps maintain precise temperature control, reducing material stress and improving overall process stability.

Applications

In cleaning & washing operations, the nozzle's flat spray pattern enables effective removal of particulate matter and residues, optimizing equipment maintenance routines. Additionally, its role in cooling & quenching supports rapid temperature reduction, which directly impacts product quality and cycle efficiency in downstream processes.

Industries

Sectors such as automotive, steel & metals, and Energy prioritize the NPHVL-4005-1/8-SS for its corrosion resistance and reliable spray distribution under demanding conditions. The nozzle is also favored in food & beverage and building materials industries where consistent application and material compatibility are critical for operational reliability.