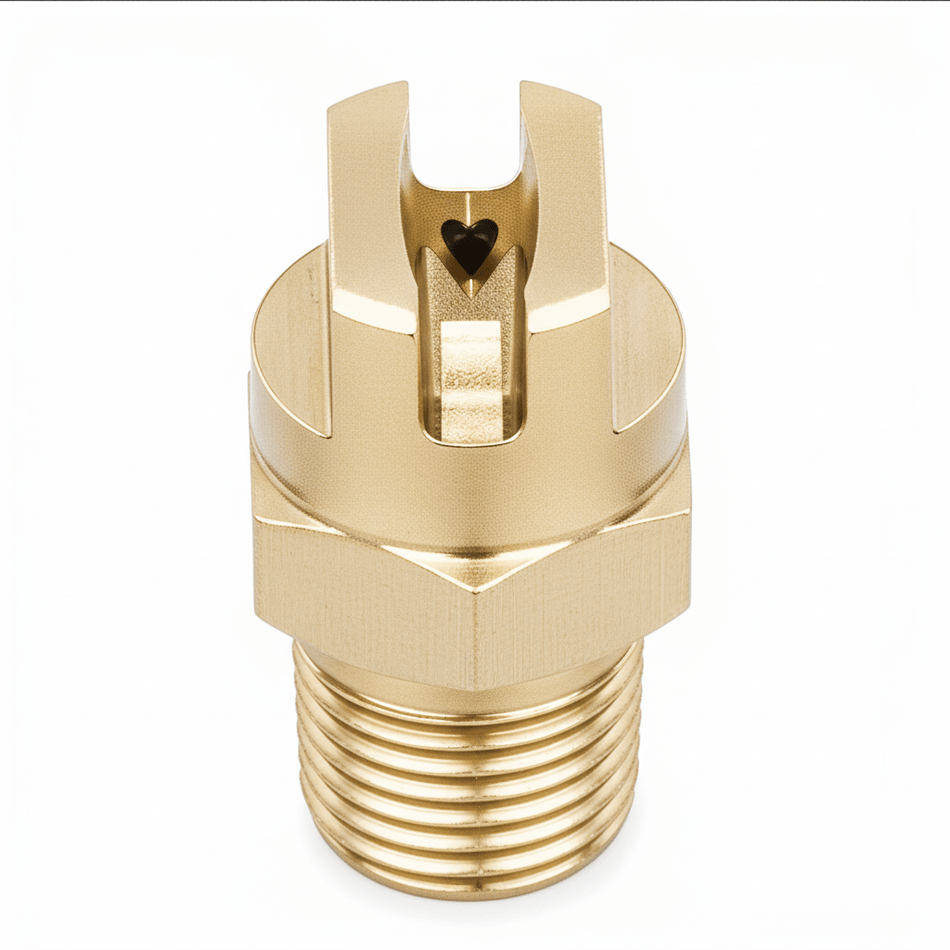

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 40 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

Inside the food & beverage line's cooling & quenching stage, a process engineer relies on the NPHVL-4003-1/8 to deliver consistent fluid coverage while maintaining system efficiency. Constructed from brass, the nozzle's flat spray pattern ensures uniform application across product surfaces, reducing thermal hotspots and preserving quality. The corrosion-resistant material extends service life in demanding environments where moisture and chemicals are present. By integrating this nozzle, operators achieve reliable performance metrics in heat dissipation and surface cleanliness.

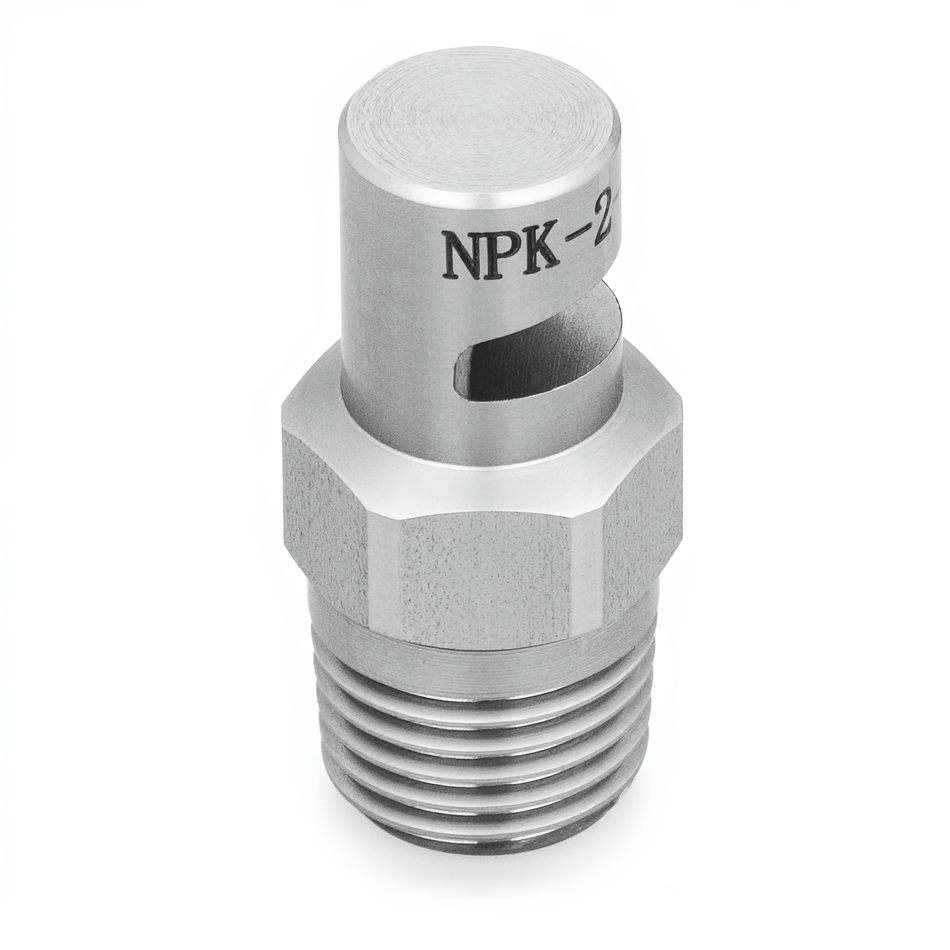

Applications

The uniform spray provided by the nozzle supports cleaning & washing operations by effectively removing residues without damaging delicate components. In cooling & quenching processes, the controlled flat spray helps regulate temperature quickly and evenly, minimizing downtime and improving throughput.

Industries

Sectors such as automotive, manufacturing & assembly, and steel & metals utilize this nozzle for its durability and spray consistency, essential for precise coating and surface treatment tasks. Additionally, food & beverage, cement, and energy industries benefit from the nozzle's resistance to corrosion and its ability to perform under continuous operation in harsh conditions.