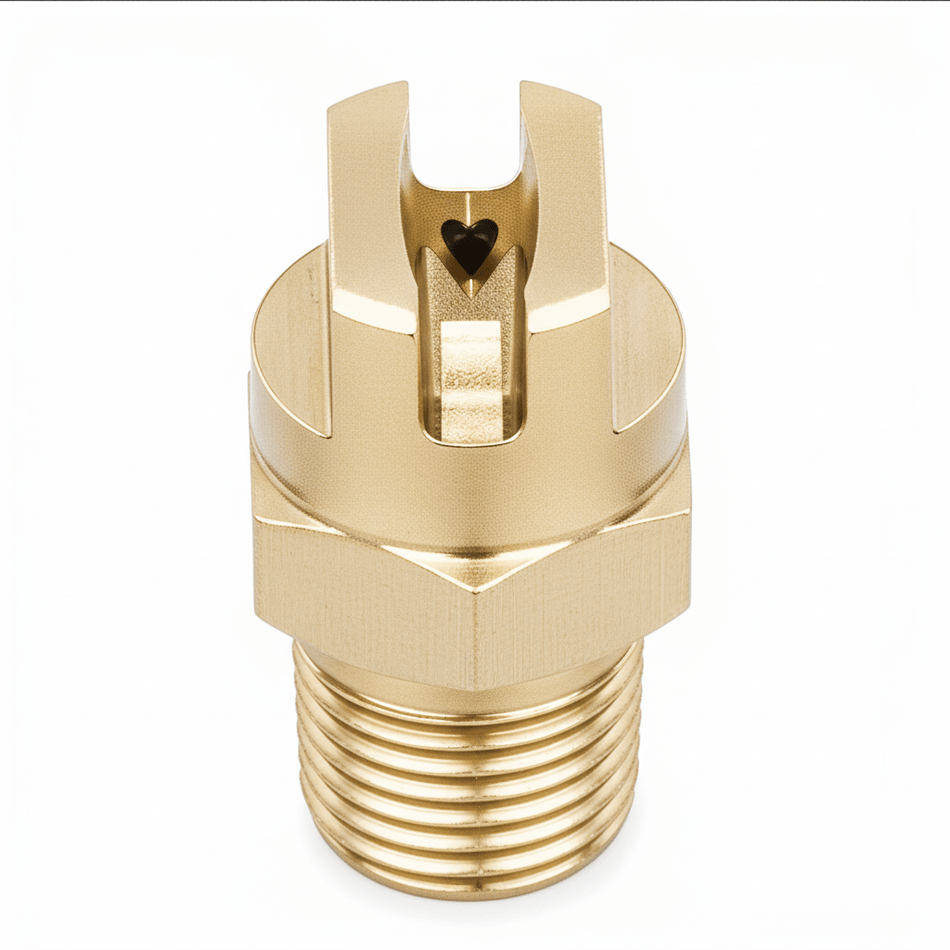

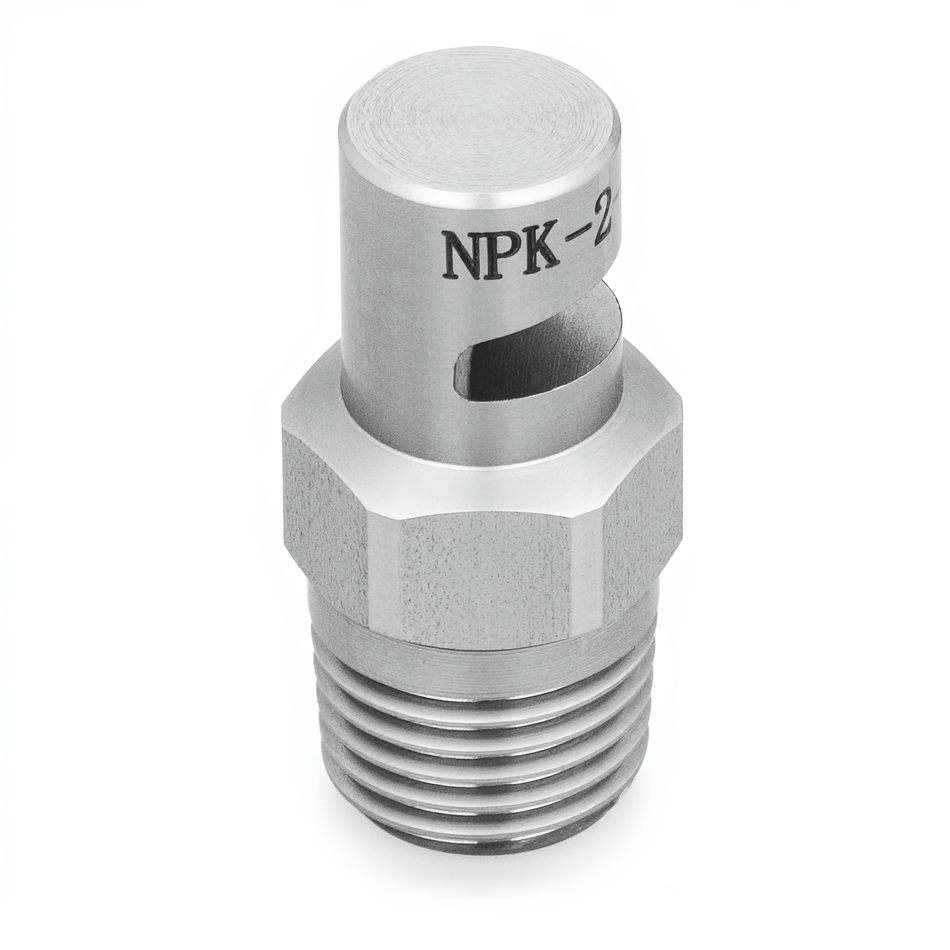

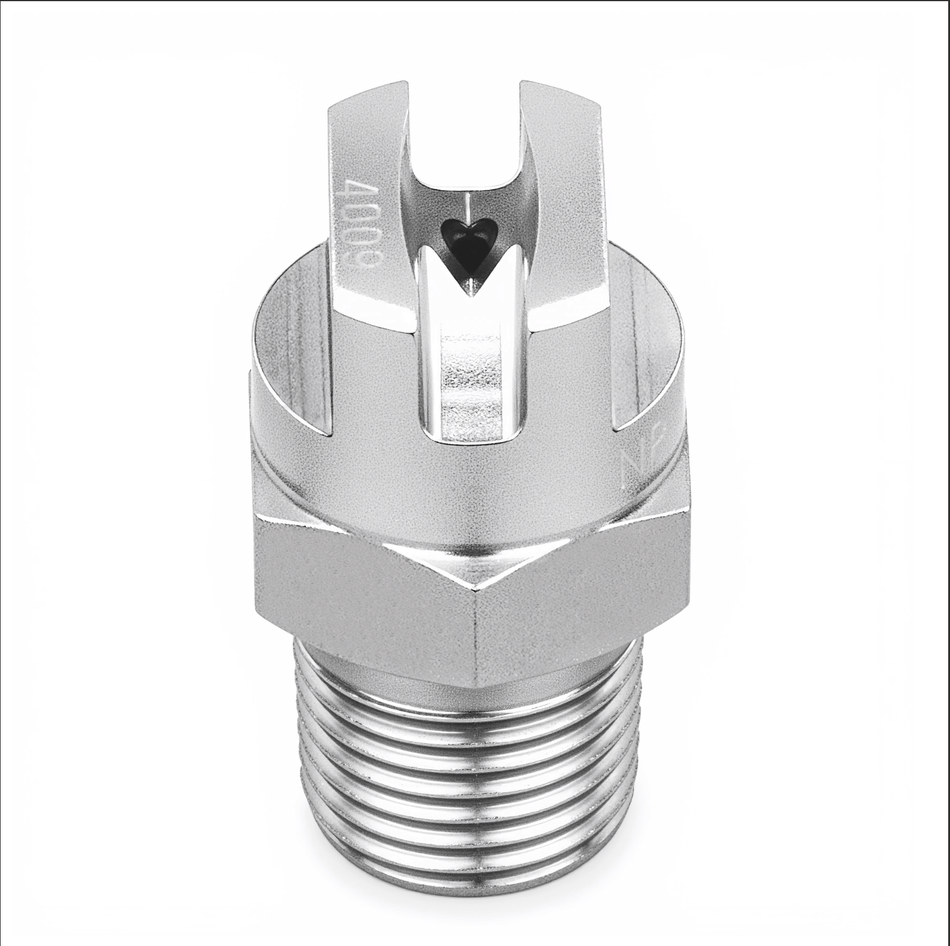

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 4 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.05 |

| Spray Angle at Rated Pressure (PSI) | 25 |

| Equivalent Orifice Diameter (mm) | 1.3 |

Description

Product Overview

When bakery & confectionery crews manage dust & pollution control, the NPHVL-2504-1/8-316 lets each process engineer deploy a reliable solution crafted from 316L stainless steel. The flat spray pattern ensures even coverage across targeted surfaces, reducing airborne particulates effectively. Operators connect the nozzle to a 1/8 inlet line and monitor consistent performance under high-demand conditions, benefiting from the corrosion-resistant material to maintain long service life despite exposure to moisture and cleaning agents. This nozzle supports process stability by delivering uniform flow rates critical to minimizing operational downtime.

Applications

In cleaning & washing processes, the NPHVL-2504-1/8-316 provides consistent flat spray coverage that enhances surface cleanliness and reduces residual buildup. Its precise spray distribution also supports cooling & quenching tasks by delivering uniform liquid application, which helps maintain consistent material properties downstream.

Industries

Sectors such as automotive, mining, and steel & metals rely on this nozzle for its durability and spray uniformity under harsh conditions. Additionally, industries like food & beverage, beverage bottling & packaging, and manufacturing & assembly select the NPHVL-2504-1/8-316 to meet stringent cleanliness and corrosion resistance standards necessary for controlled production environments.