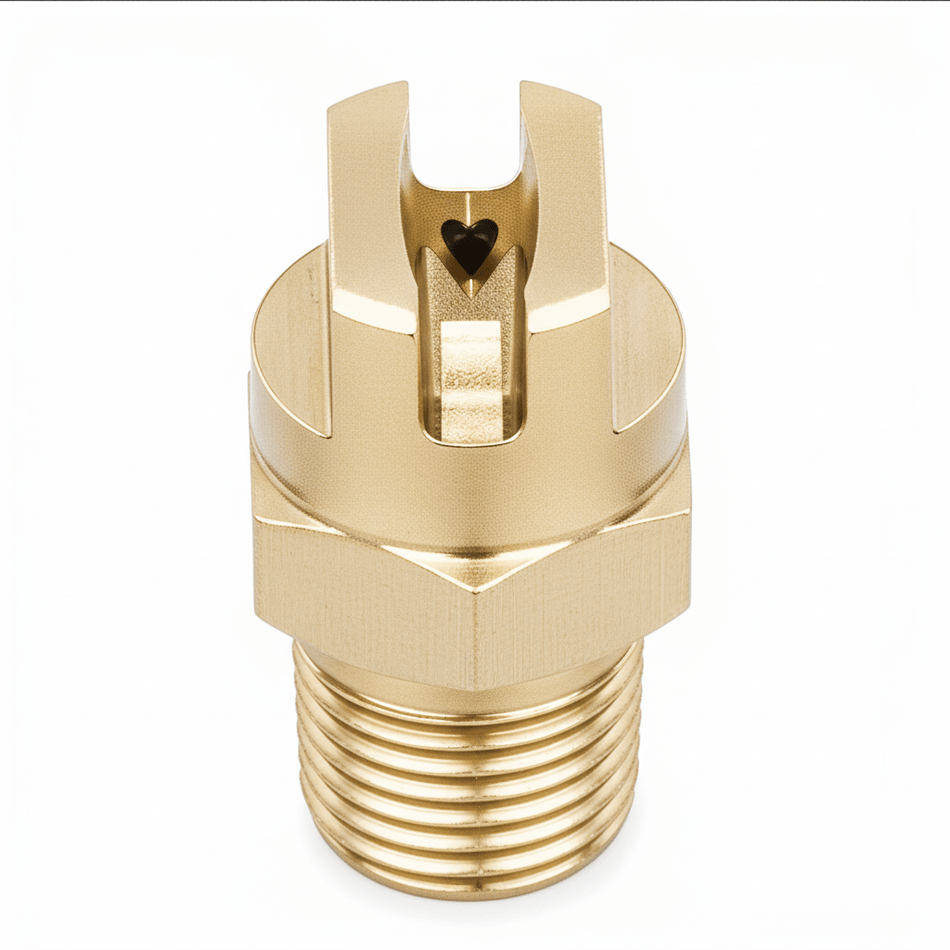

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 25 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

A plant operator in the roofing facility uses the NPHVL-2503-1/8 during dust & pollution control to deliver a consistent flat spray pattern that covers large surface areas efficiently. Constructed from durable brass, the nozzle withstands exposure to corrosive elements commonly encountered in industrial environments. By maintaining uniform spray distribution, the operator ensures effective suppression of airborne particulates while minimizing water consumption and equipment wear. This precise control contributes to meeting environmental compliance standards and maintaining clean work conditions.

Applications

This nozzle is well-suited for cleaning & washing tasks where even coverage and corrosion resistance are critical for long service life. In cooling & quenching processes, its flat spray pattern helps achieve consistent temperature control, improving material quality and throughput.

Industries

The NPHVL-2503-1/8 is favored in automotive, building materials, and Energy sectors for its reliability in harsh conditions and consistent spray characteristics. Additionally, industries such as food & beverage, steel & metals, and manufacturing & assembly utilize this nozzle to support processes requiring precise liquid distribution and resistance to wear.