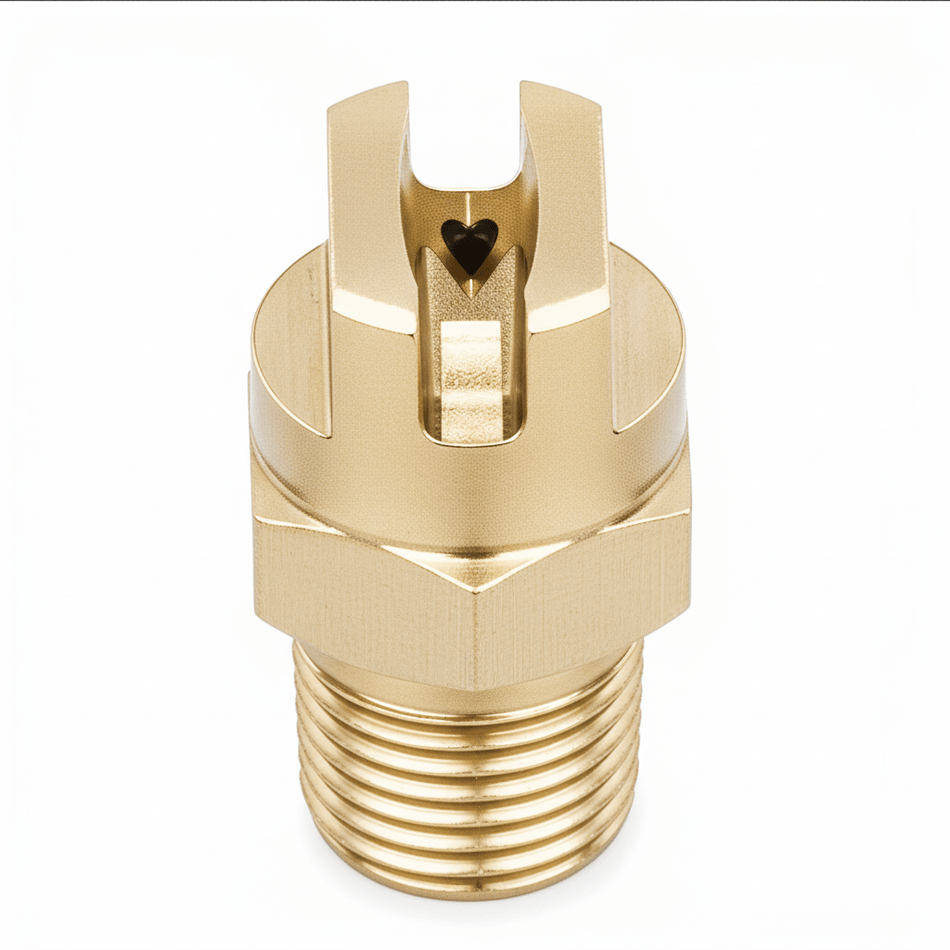

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 25 |

| Equivalent Orifice Diameter (mm) | 1.1 |

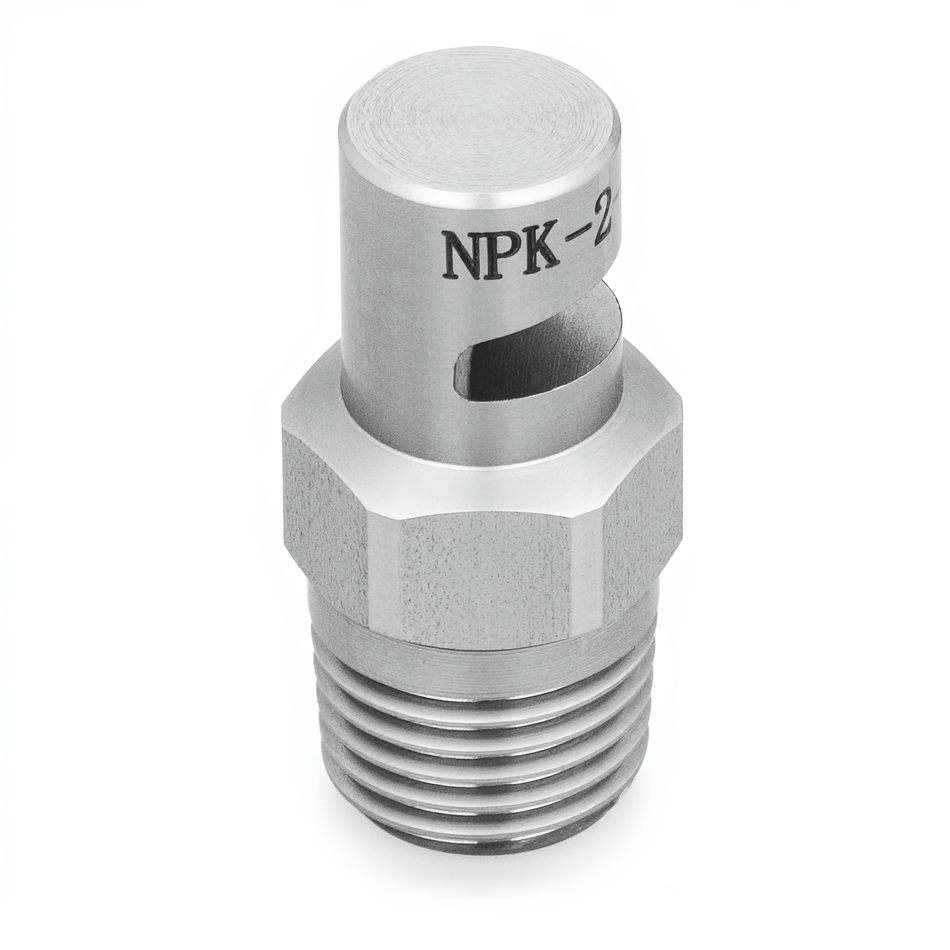

Description

Product Overview

When cement crews manage cleaning & washing, the NPHVL-2503-1/8-316 lets each production technician rely on a durable 316L stainless steel construction to withstand abrasive environments. The flat spray pattern delivers consistent coverage, optimizing surface preparation and residue removal. Installing the NPHVL-2503-1/8-316 with its 1/8 inlet ensures compatibility with existing piping systems while maintaining corrosion resistance that extends service intervals. Operators benefit from predictable nozzle performance that contributes to maintaining process efficiency in harsh conditions.

Applications

In cleaning & washing scenarios, this nozzle achieves uniform spray distribution critical for thorough surface treatment and contamination removal. Additionally, its role in cooling & quenching processes helps manage temperature control, reducing thermal stress on materials and equipment downstream.

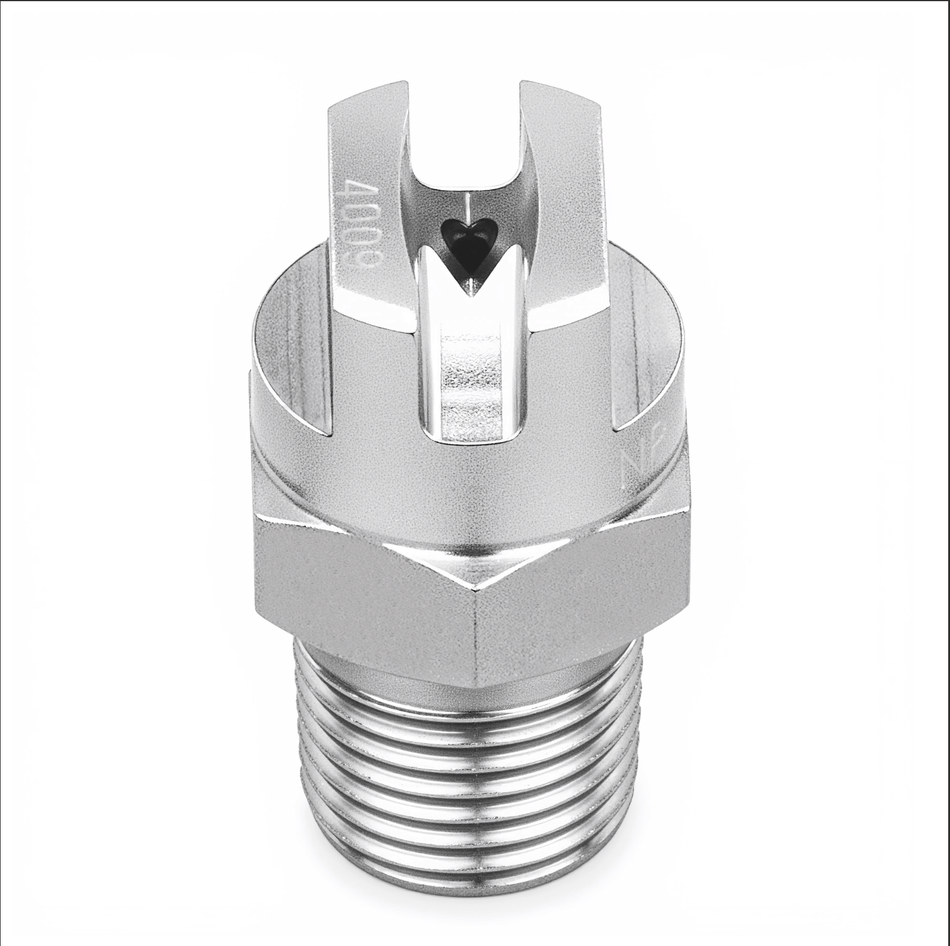

Industries

The NPHVL-2503-1/8-316 is frequently utilized in automotive, steel & metals, and mining sectors where corrosion resistance and spray consistency are essential. These industries, along with building materials and food & beverage processing, rely on this nozzle to meet stringent operational standards and enhance process reliability.