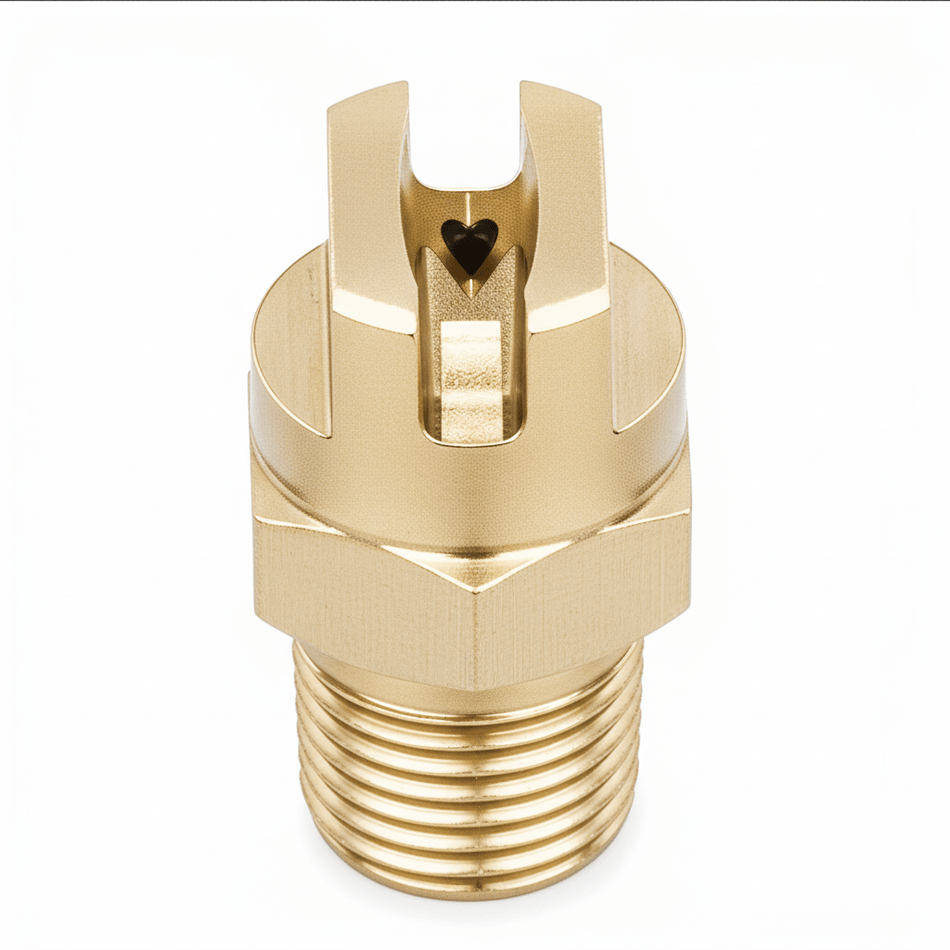

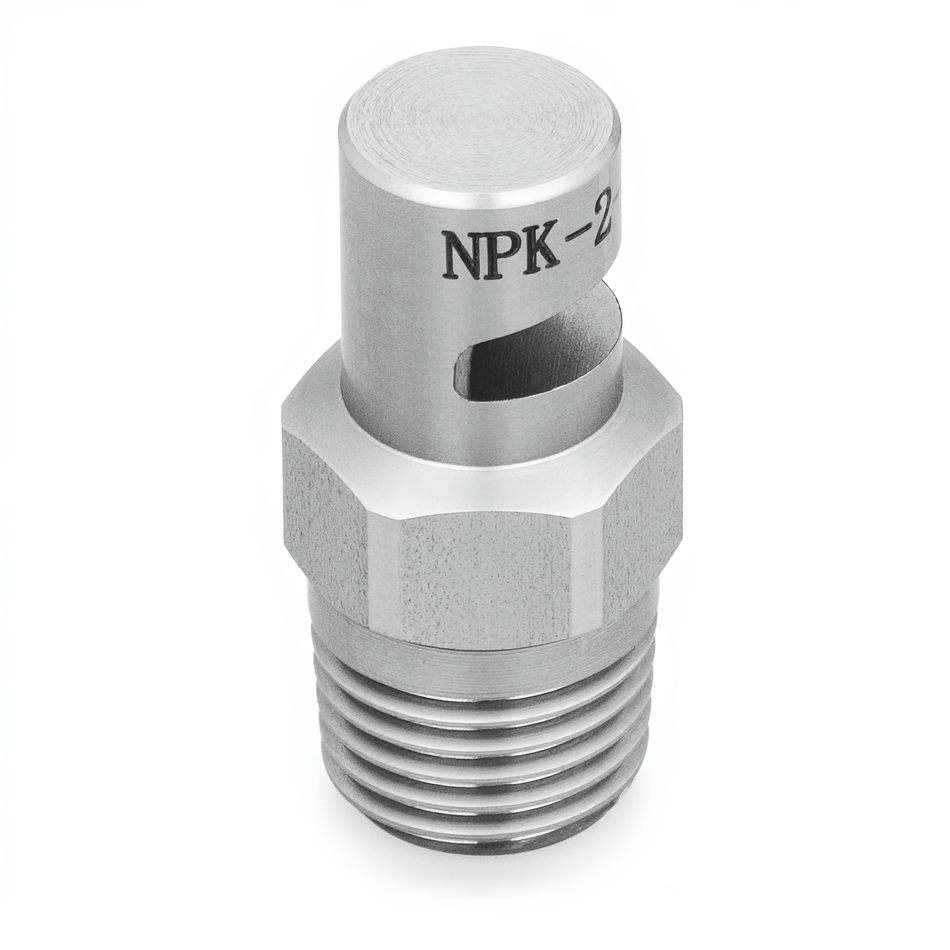

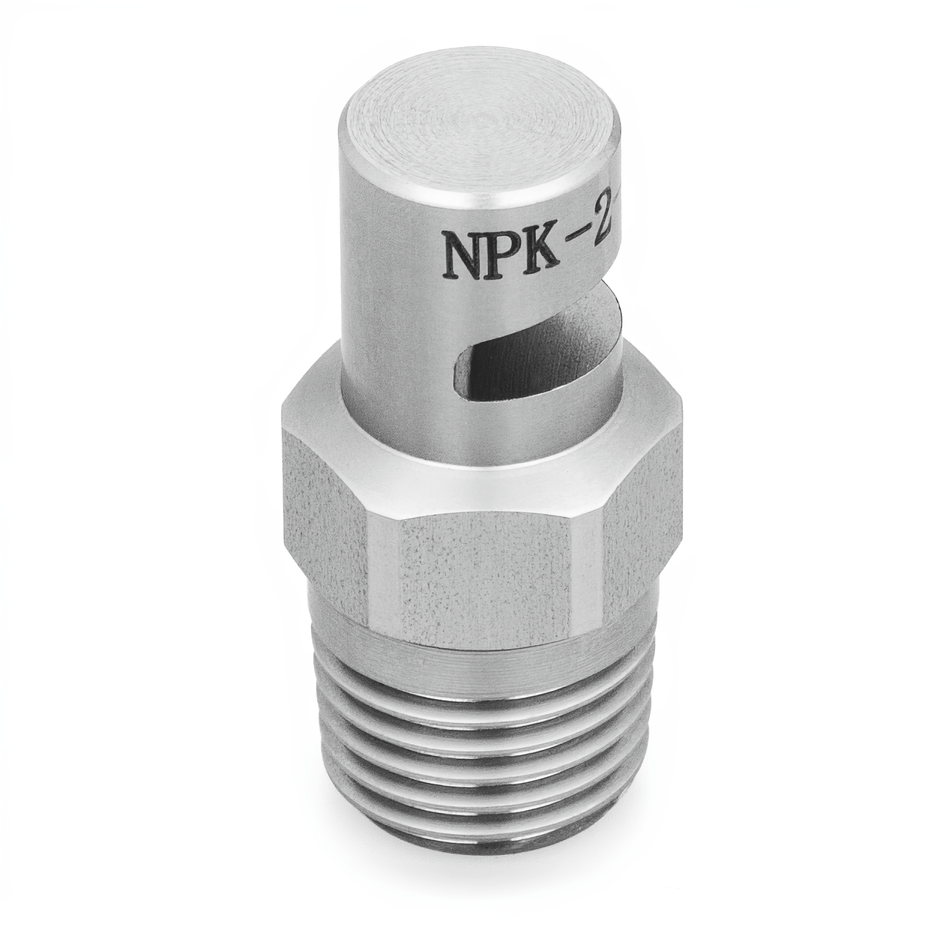

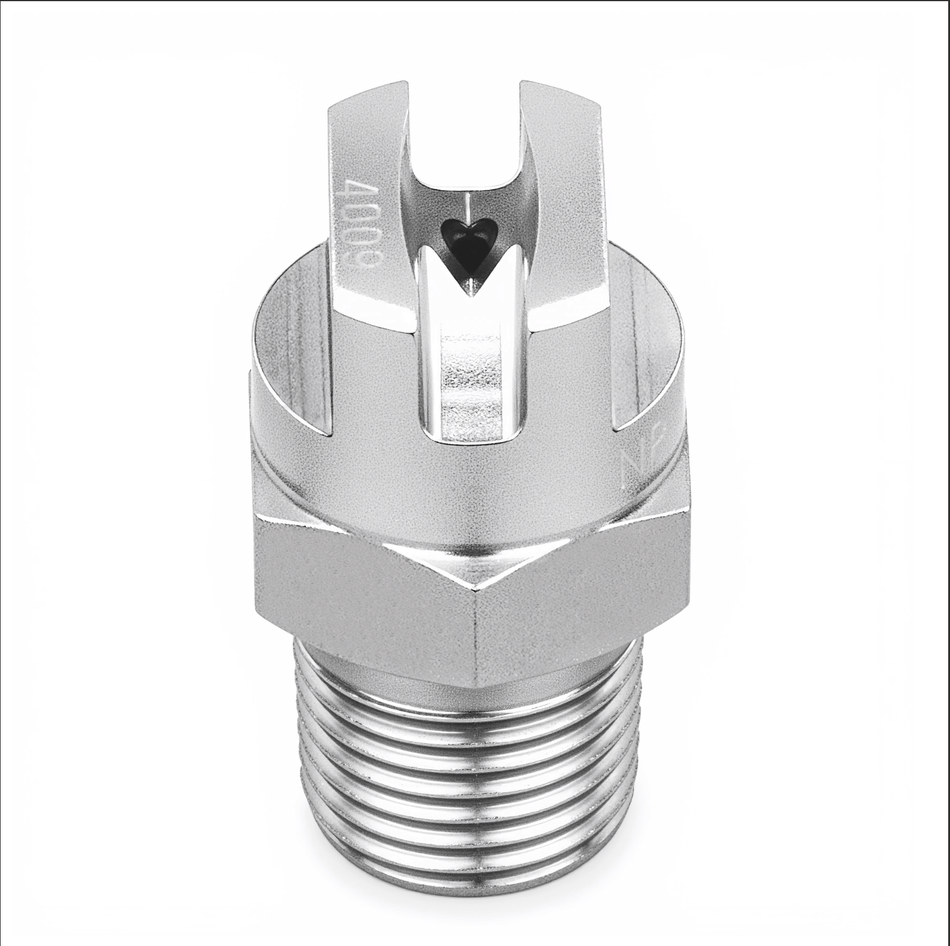

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 2 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.035 |

| Spray Angle at Rated Pressure (PSI) | 25 |

| Equivalent Orifice Diameter (mm) | 0.89 |

Description

Product Overview

Inside the steel & metals line's cooling & quenching stage, a process engineer relies on the NPHVL-2502-1/8-316 to deliver consistent flat spray coverage essential for uniform temperature control. Constructed from 316L stainless steel, this nozzle resists corrosion over extended cycles in harsh environments. With its 1/8 inch inlet, the nozzle integrates seamlessly into existing piping systems, enabling precise fluid distribution. Operators monitor spray uniformity and flow rate to ensure optimal cooling performance and reduce material stress.

Applications

In cooling & quenching operations, the NPHVL-2502-1/8-316 promotes even thermal regulation, which directly impacts product quality and cycle time. Additionally, it supports cleaning & washing processes by providing targeted spray coverage that enhances residue removal without excess water usage.

Industries

This nozzle is favored in automotive, mining, and steel & metals sectors due to its durability and reliable spray pattern under demanding conditions. Food & beverage and building materials industries also utilize the nozzle where corrosion resistance and precise fluid delivery are critical to maintaining product integrity and process efficiency.