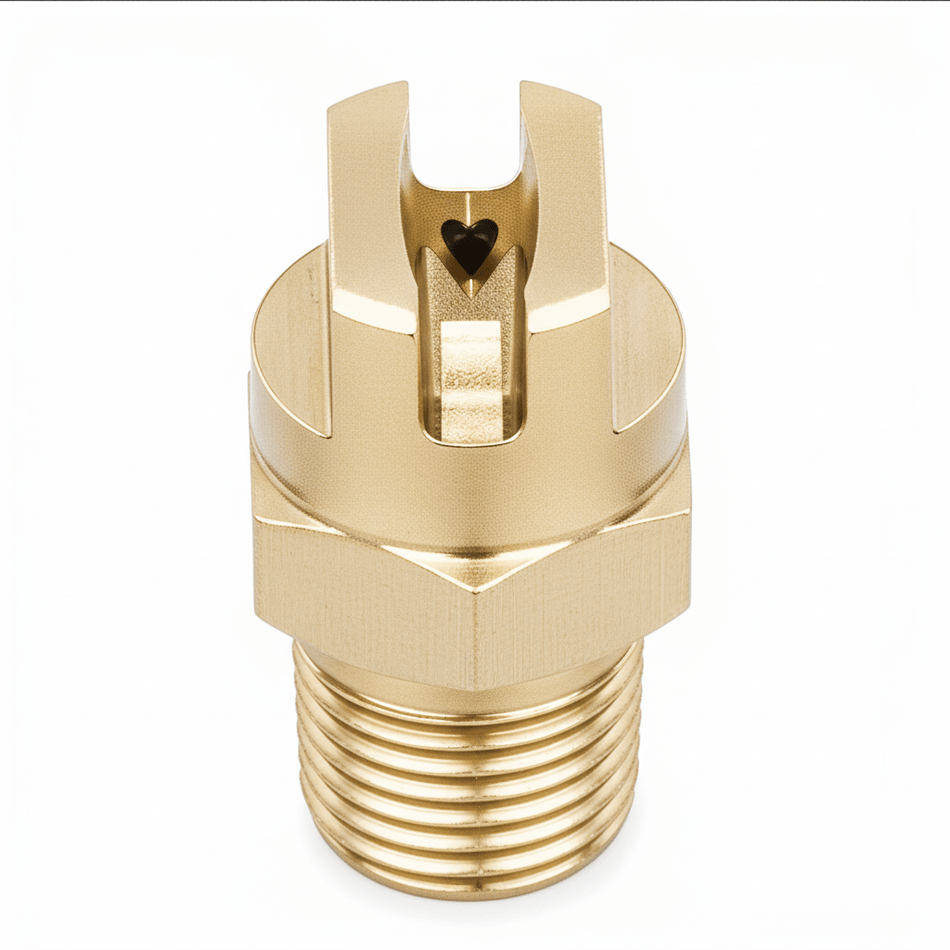

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHVL |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 36 |

| Length (in) | 1.531 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 15 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

When breweries & wineries crews manage dust & pollution control, the NPHVL-1503-1/8 lets each plant operator integrate a brass flat nozzle with a 1/8 inlet to achieve consistent spray coverage. Installing the nozzle on automated spray bars, operators benefit from the uniform flat spray pattern that optimizes surface wetting without excessive overspray. The corrosion-resistant brass construction ensures durability under frequent exposure to cleaning agents and high humidity environments, contributing to reliable performance over time. This precision nozzle delivers measurable improvements in controlling particulate dispersion during routine maintenance cycles.

Applications

In cleaning & washing operations, the NPHVL-1503-1/8 applies fluid uniformly to remove residues and contaminants effectively, reducing downtime between production runs. Its role in dust & pollution control helps maintain regulatory compliance by minimizing airborne particles, which supports safer working conditions and improved product quality.

Industries

Sectors such as automotive, food & beverage, and steel & metals rely on the NPHVL-1503-1/8 due to its ability to deliver consistent spray patterns needed for coating & surface treatment and cooling & quenching tasks. Additionally, industries like building materials and mining select this nozzle for its resistance to corrosion and abrasion in harsh manufacturing environments.