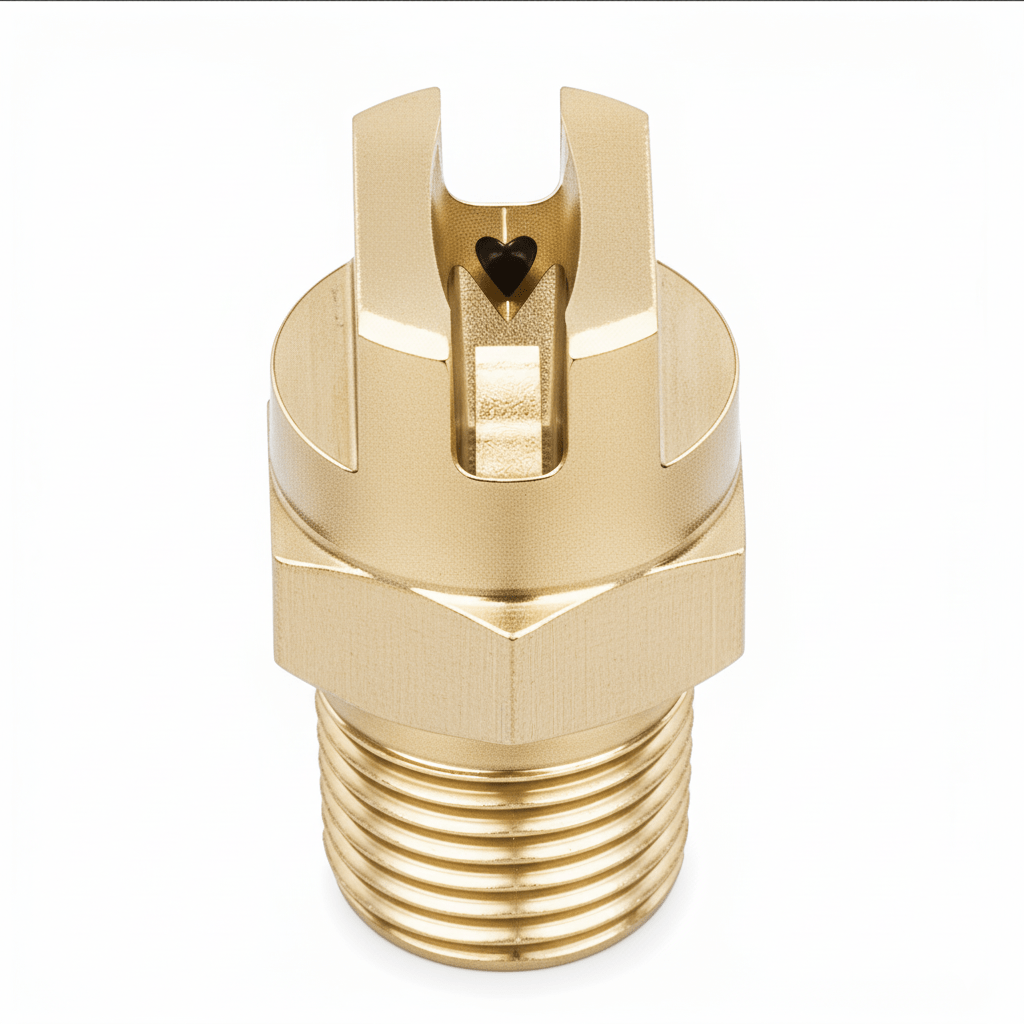

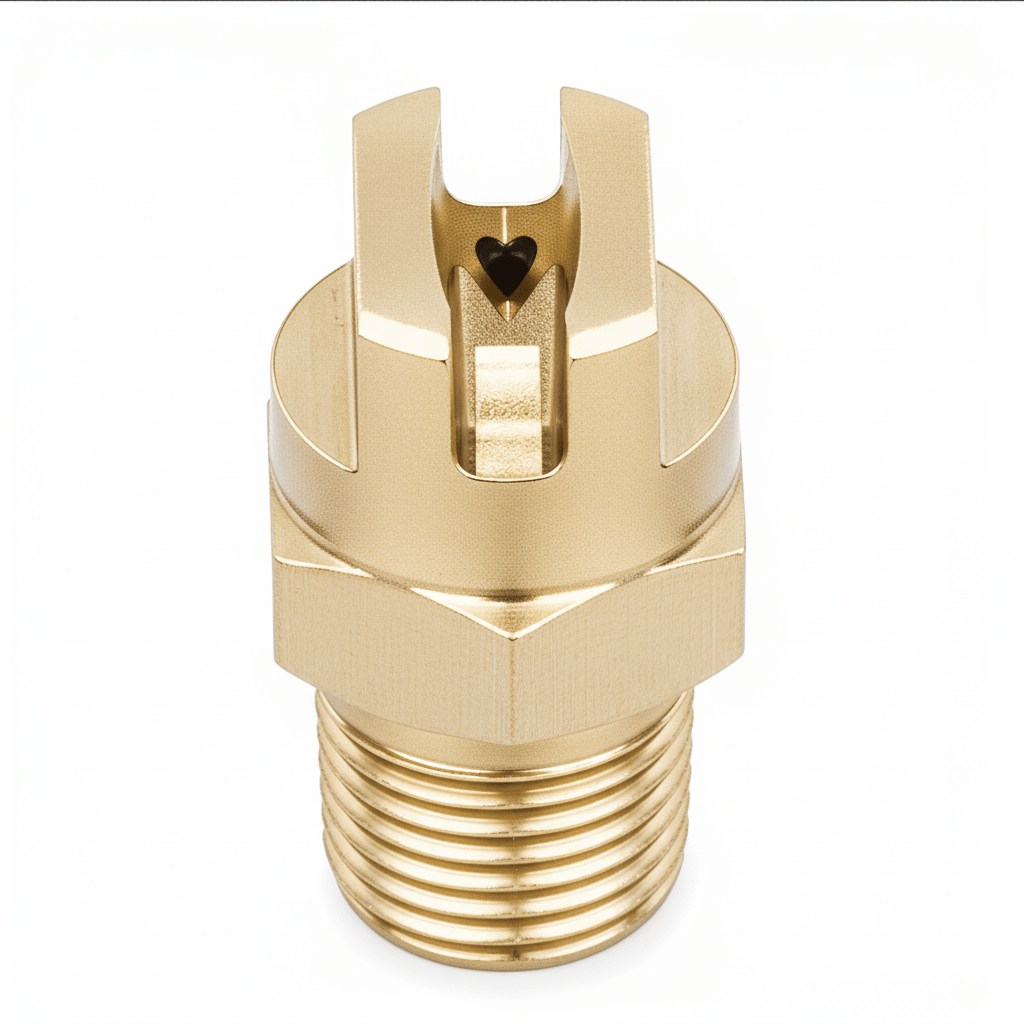

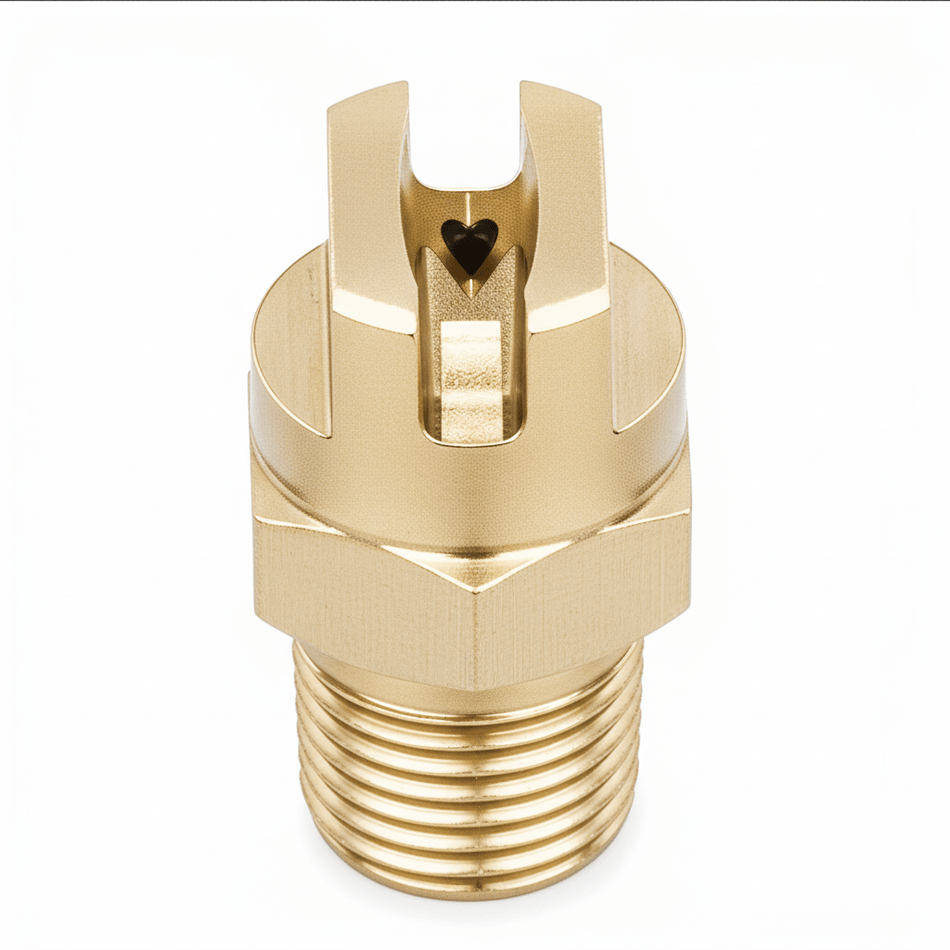

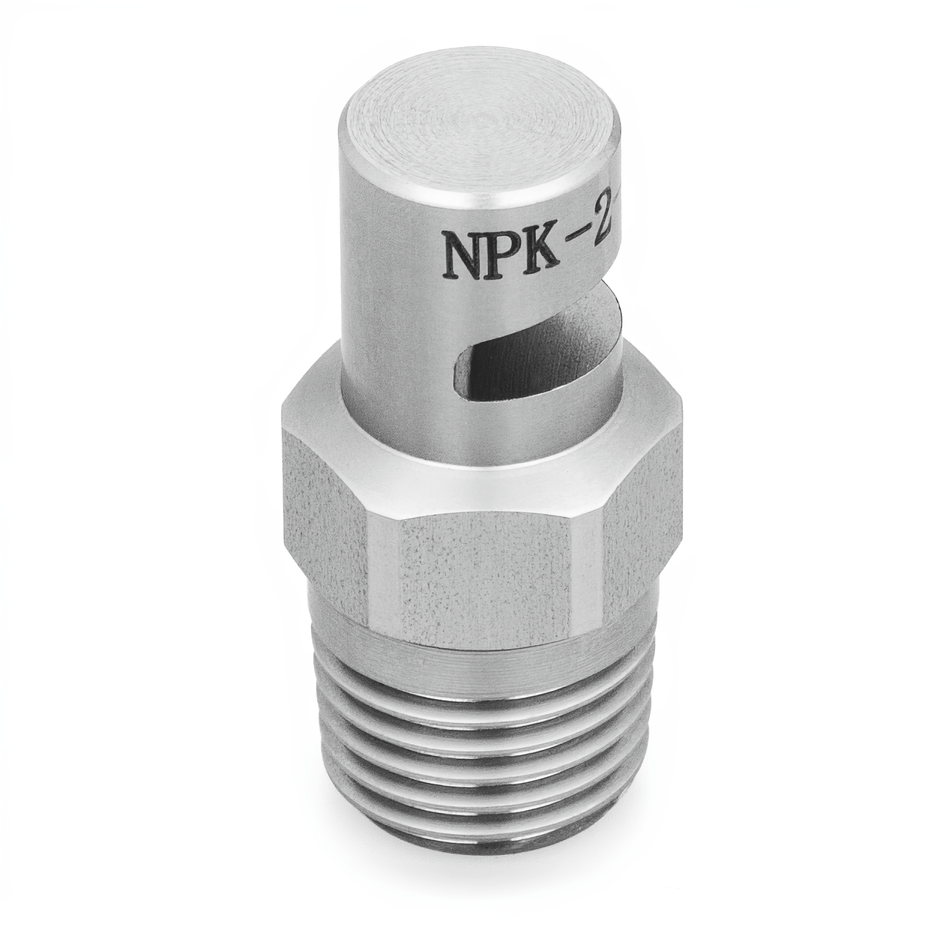

Product Parameters

| Product Family | Flat |

|---|---|

| Product Series | NPHV |

| Capacity Size | 3 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 22 |

| Length (in) | 0.875 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.043 |

| Spray Angle at Rated Pressure (PSI) | 65 |

| Equivalent Orifice Diameter (mm) | 1.1 |

Description

Product Overview

Inside the roofing line's cooling & quenching stage, a plant operator relies on the NPHV-6503-1/8 to deliver consistent flat spray coverage that maintains product integrity during rapid temperature changes. Constructed from brass, the nozzle withstands corrosive environments common in quenching baths, ensuring longevity and minimal downtime. Its 1/8-inch inlet provides controlled flow rates critical for uniform cooling, reducing thermal stress on roofing materials. By maintaining precise spray patterns, the operator can optimize cycle times and quality control metrics effectively.

Applications

This nozzle plays a crucial role in cooling & quenching operations by providing stable and even fluid distribution, which helps prevent material deformation and improves throughput consistency. Additionally, its resistance to corrosion supports cleaning & washing processes, allowing operators to maintain equipment cleanliness without frequent nozzle replacement.

Industries

Sectors such as automotive, steel & metals, and manufacturing & assembly frequently utilize this nozzle for processes requiring reliable spray patterns and durability under harsh conditions. The food & beverage and beverage bottling & packaging industries also depend on its corrosion resistance and precise flow control for specialty applications and hygiene-critical operations.