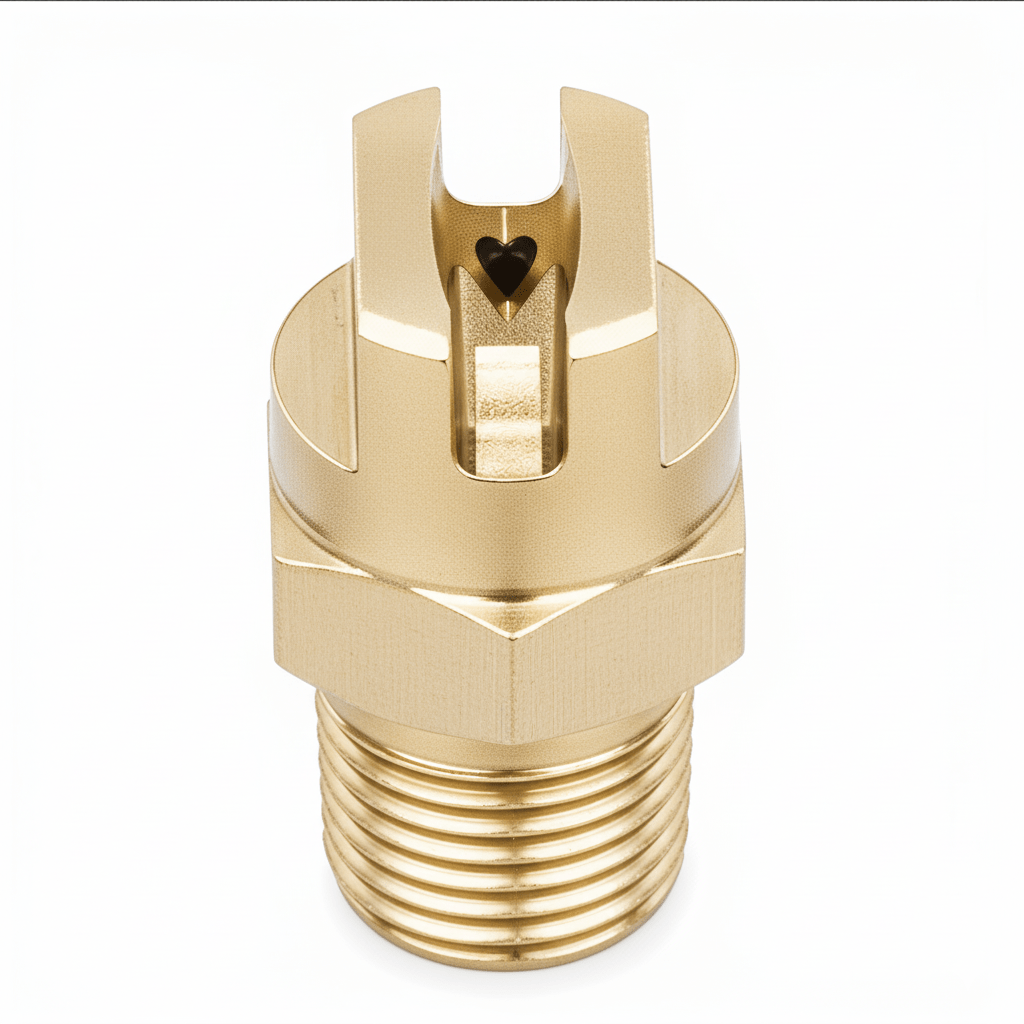

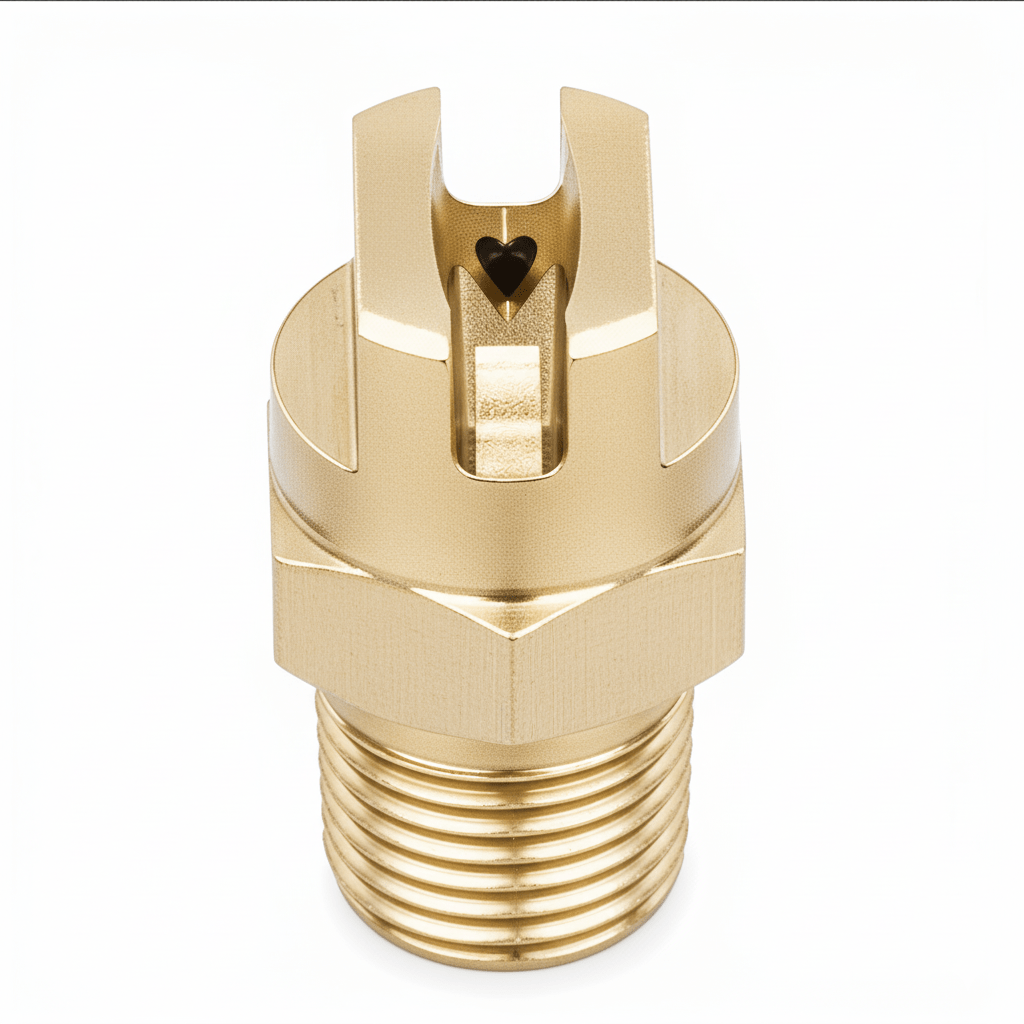

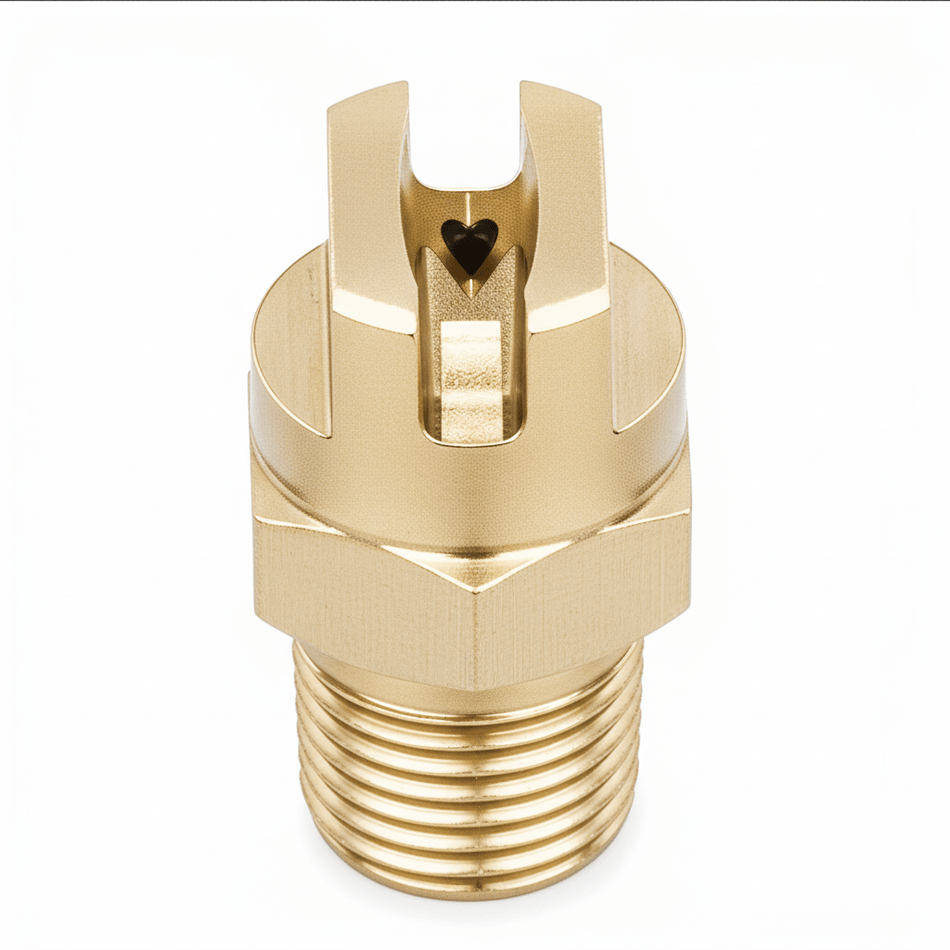

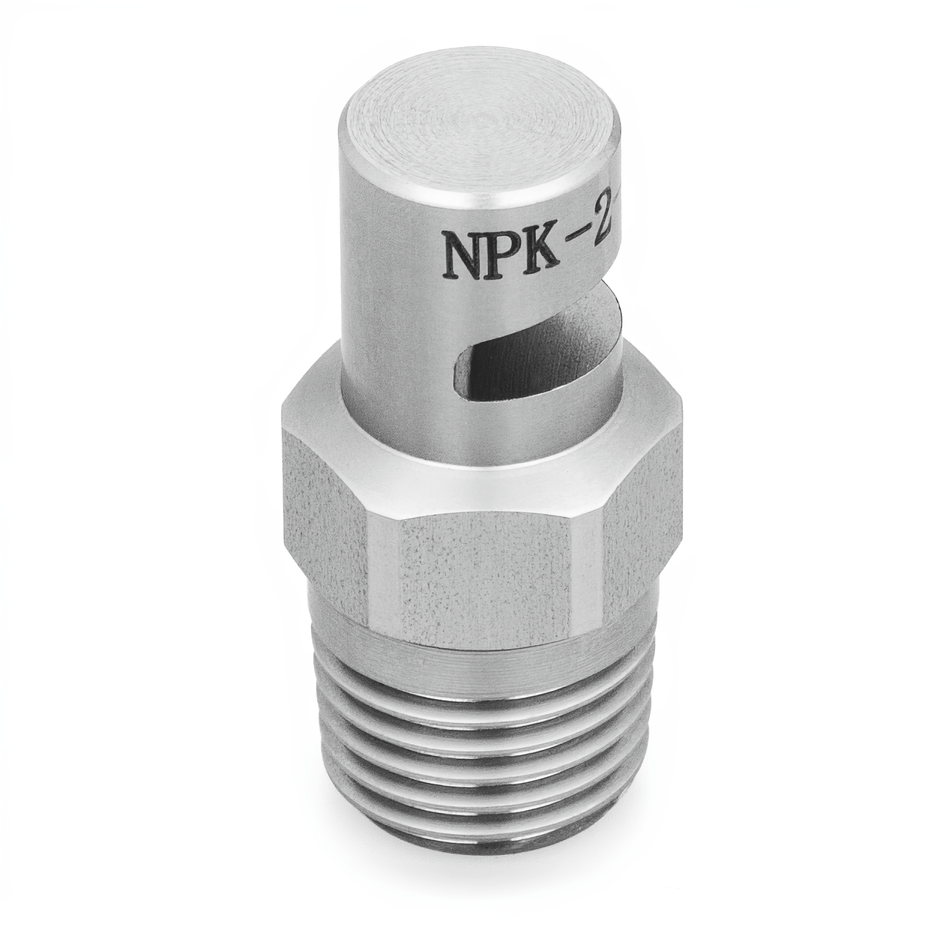

Product Parameters

| Product Family | Flat |

|---|---|

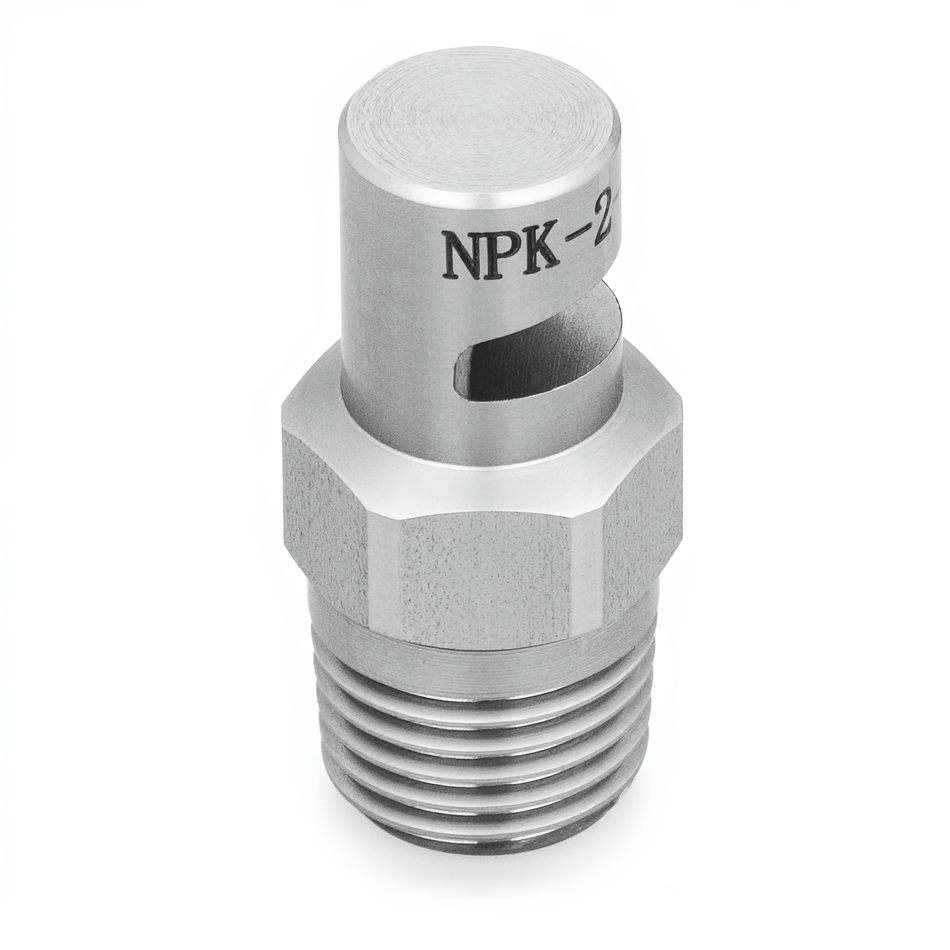

| Product Series | NPHV |

| Capacity Size | 2 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 1/8 |

| Length (mm) | 22 |

| Length (in) | 0.875 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 1/2 |

| Equivalent Orifice Diameter (in) | 0.035 |

| Spray Angle at Rated Pressure (PSI) | 40 |

| Equivalent Orifice Diameter (mm) | 0.89 |

Description

Product Overview

During cooling & quenching on a bakery & confectionery site, quality managers trust the NPHV-4002-1/8 to deliver consistent spray coverage that helps maintain product integrity. Operators install the brass flat nozzle with its 1/8 inlet carefully onto the spray manifold to ensure a uniform distribution of coolant across baking surfaces. The corrosion-resistant material supports long service life despite exposure to moisture and varying temperatures. This precise spray pattern helps reduce waste and improves process reliability in temperature-sensitive production stages.

Applications

In processes involving cooling & quenching, the nozzle's uniform flat spray pattern contributes to effective temperature control, which is essential for product quality and equipment longevity. Cleaning & washing applications downstream also benefit from consistent spray coverage, minimizing residue buildup and reducing downtime.

Industries

Sectors such as automotive, food & beverage, and steel & metals utilize the NPHV-4002-1/8 because the nozzle's durability and uniform spray pattern accommodate highly regulated environments and demanding operational conditions. Additionally, industries like building materials, mining, and breweries & wineries rely on it for consistent fluid application that supports process stability and equipment maintenance.