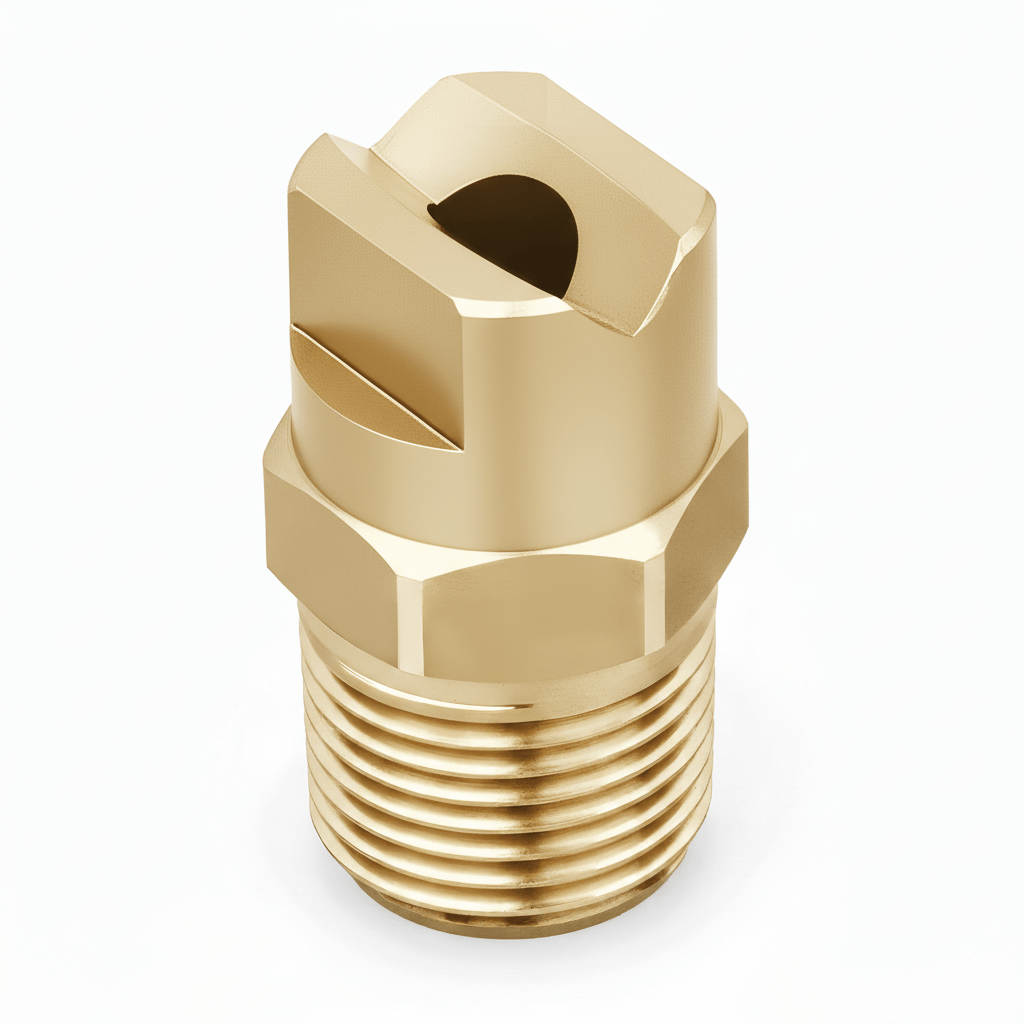

Product Parameters

| Product Family | Flat |

|---|---|

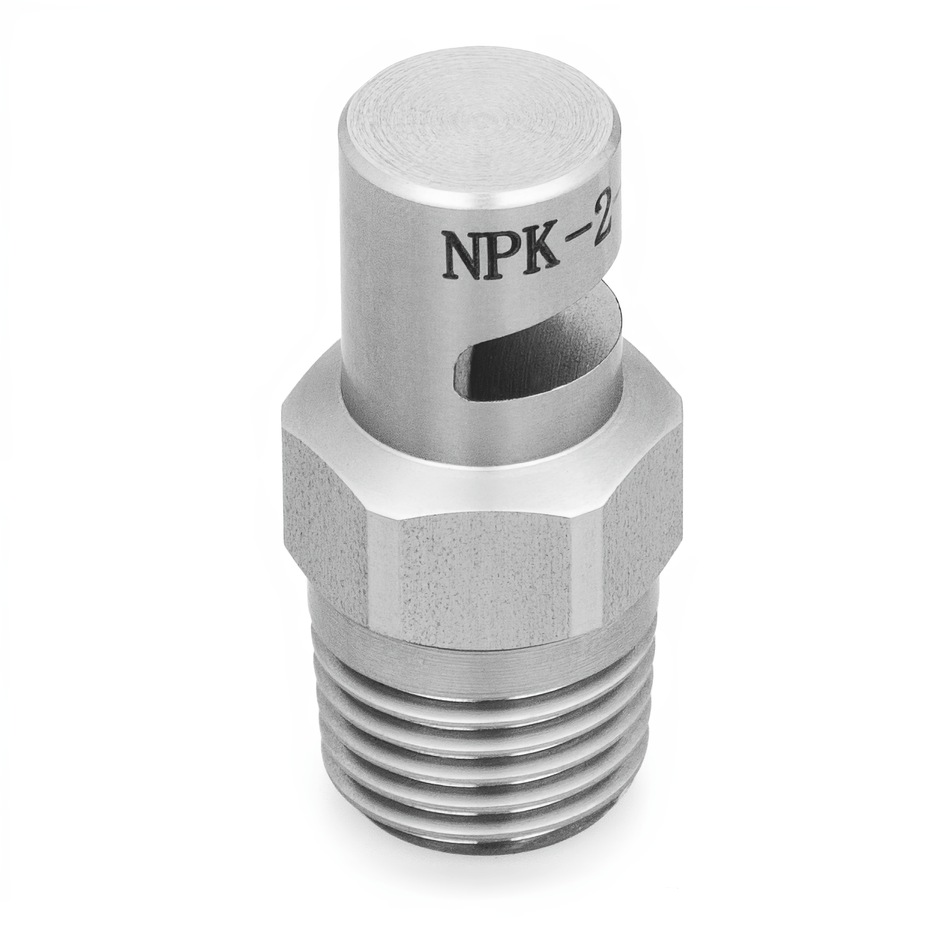

| Product Series | NPHU |

| Capacity Size | 30 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 22 |

| Length (in) | 1.250 |

| Hex Size (mm) | 12.7 |

| Hex Size (in) | 11/16 |

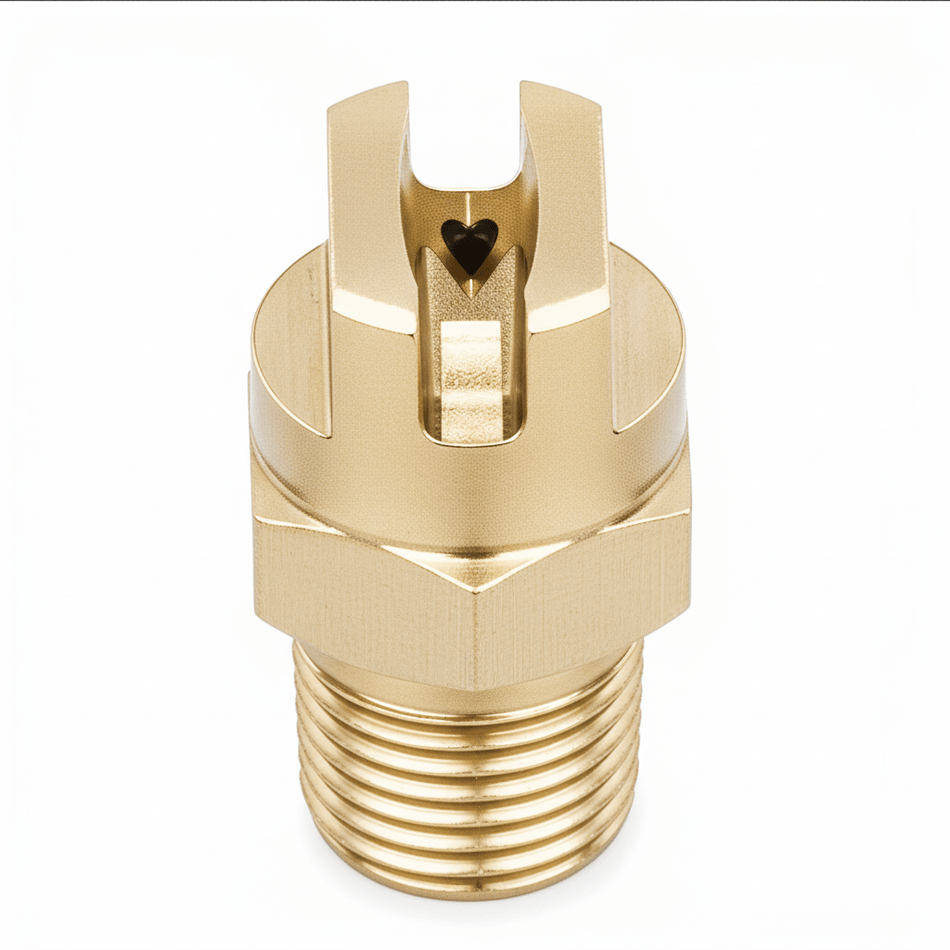

| Equivalent Orifice Diameter (in) | 0.129 |

| Spray Angle at Rated Pressure (PSI) | 80 |

| Equivalent Orifice Diameter (mm) | 3.4 |

Description

Product Overview

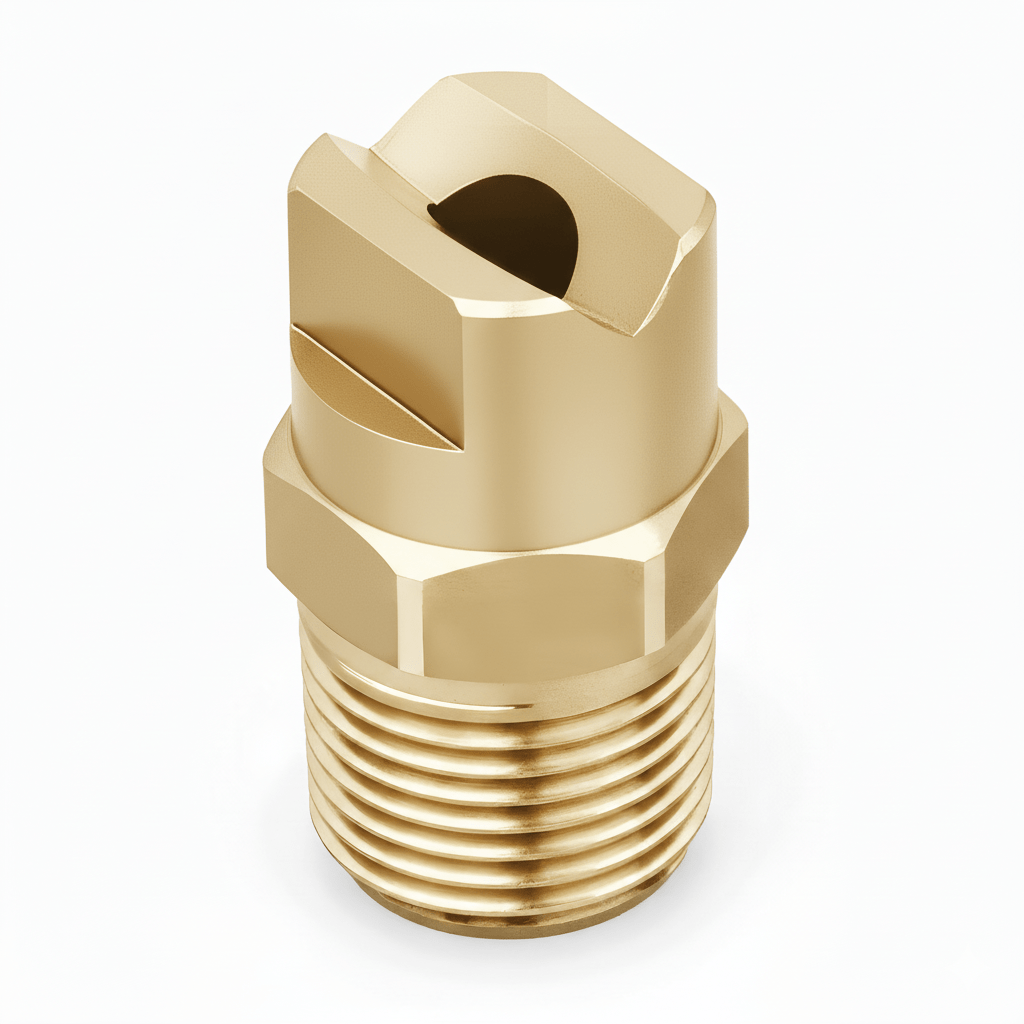

Inside the beverage bottling & packaging line's cooling & quenching stage, a process engineer relies on the NPHU-8030-3/8 to deliver a consistent flat spray that rapidly cools containers without causing distortion. Constructed from brass, the nozzle withstands corrosion from continuous exposure to water and cleaning agents, maintaining reliable performance over time. Operators calibrate flow rates through the 3/8 inlet to optimize spray coverage and ensure uniform temperature control across the production line. This precision nozzle supports efficient process control by minimizing downtime related to spray inconsistencies or material degradation.

Applications

In cleaning & washing operations, the NPHU-8030-3/8 applies a uniform flat spray that improves contaminant removal while reducing water consumption. Its role in cooling & quenching helps maintain product integrity by rapidly dissipating heat, which decreases cycle times and enhances throughput in industrial washing and heat treatment processes.

Industries

This nozzle is favored in sectors such as automotive, steel & metals, and cement, where consistent spray patterns improve surface treatment and dust control outcomes. Additionally, industries like food & beverage, dairy, and breweries & wineries benefit from its corrosion resistance and precise spray distribution, supporting hygiene and process efficiency requirements.