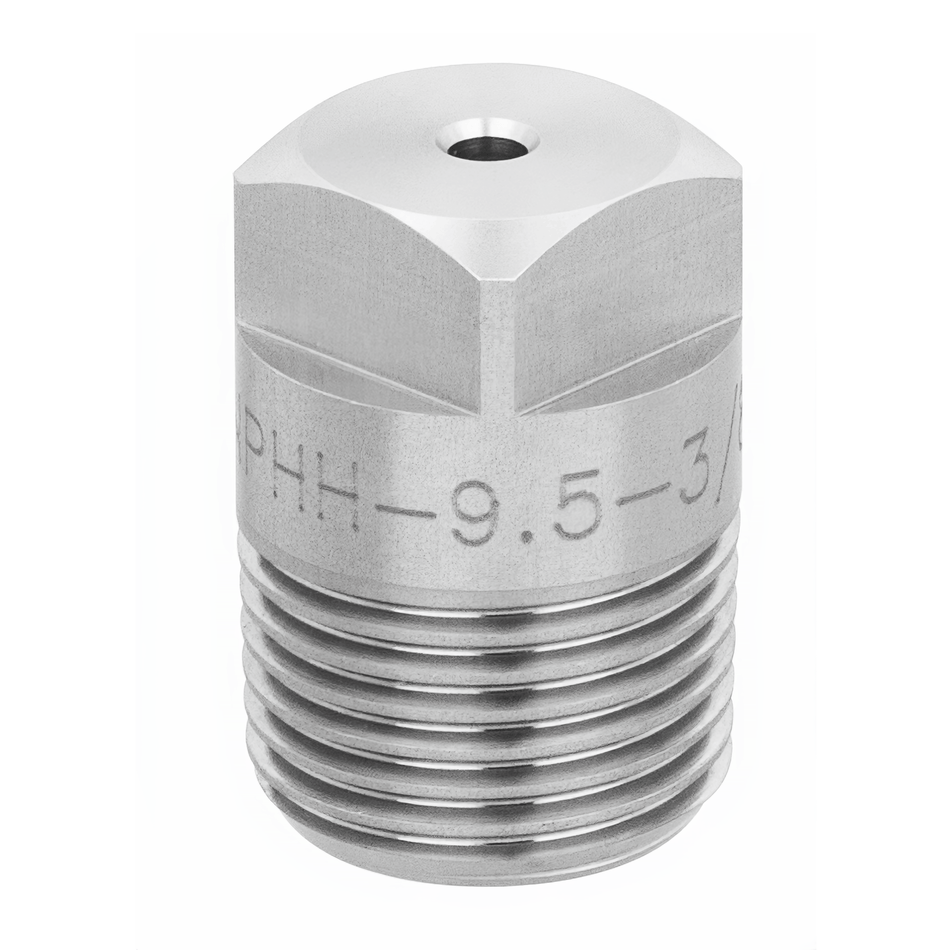

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Teflon |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 90 |

Description

Product Overview

Inside the breweries & wineries line's dust & pollution control stage, a plant operator relies on the NPHSJ-90470-1-TEF to deliver a consistent and uniform spray pattern essential for effective particulate suppression. Constructed from teflon, this full cone spiral nozzle withstands corrosive cleaning agents, enabling extended service life under continuous operation. The operator calibrates the nozzle's 1-inch inlet to achieve precise flow rates, ensuring optimal coverage while minimizing downtime caused by wear or clogging. By maintaining stable spray distribution, the NPHSJ-90470-1-TEF supports regulatory compliance and improves overall environmental management within the facility.

Applications

In dust & pollution control processes, the nozzle's ability to maintain a full cone spray pattern allows for efficient capture and reduction of airborne contaminants. Additionally, its performance in cleaning & washing applications contributes to equipment reliability and reduces the risk of cross-contamination in sensitive production environments.

Industries

Sectors such as building materials, chemical processing, and mining benefit from the NPHSJ-90470-1-TEF's corrosion resistance and consistent spray output, which are critical for operations exposed to harsh chemicals and abrasive materials. Similarly, steel & metals, breweries & wineries, and cement industries utilize this nozzle