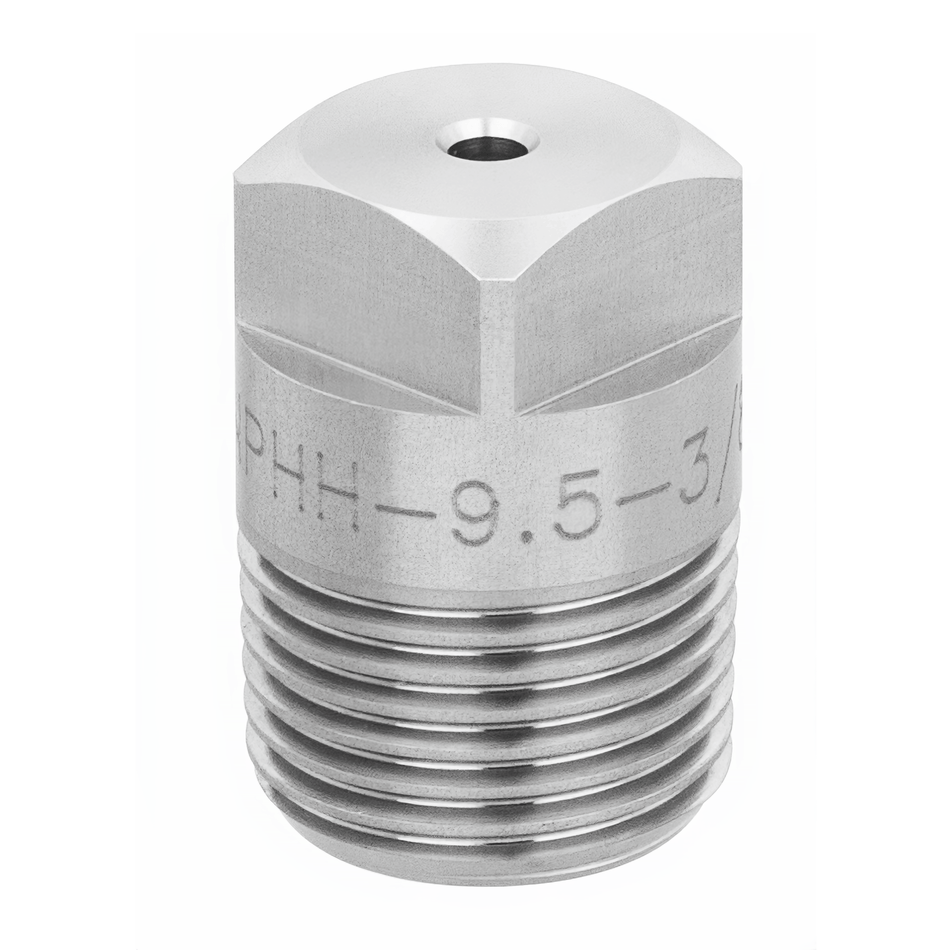

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 90 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

Inside the mining line's specialty applications stage, a production technician relies on the NPHSJ-90470-1-PP to deliver consistent fluid distribution through its full cone spiral spray pattern. Constructed from polypropylene, the nozzle withstands harsh, corrosive environments typically encountered in industrial processing. By maintaining uniform spray coverage, the operator ensures efficient material handling and dust suppression while reducing downtime caused by nozzle wear. This precision component supports optimizing flow rates and minimizing waste in critical process steps.

Applications

In cleaning & washing operations, the uniform spray pattern of the nozzle enables thorough coverage of surfaces, contributing to effective removal of residues and contaminants. Additionally, in dust & pollution control, the nozzle helps suppress airborne particles, improving environmental conditions around the process area and downstream equipment.

Industries

Sectors such as building materials, chemical processing, Energy, and mining utilize the NPHSJ-90470-1-PP for its chemical resistance and spray consistency. These features are essential for applications in steel & metals, breweries & wineries, and cement industries, where precise fluid handling and equipment protection are critical to maintaining production quality.