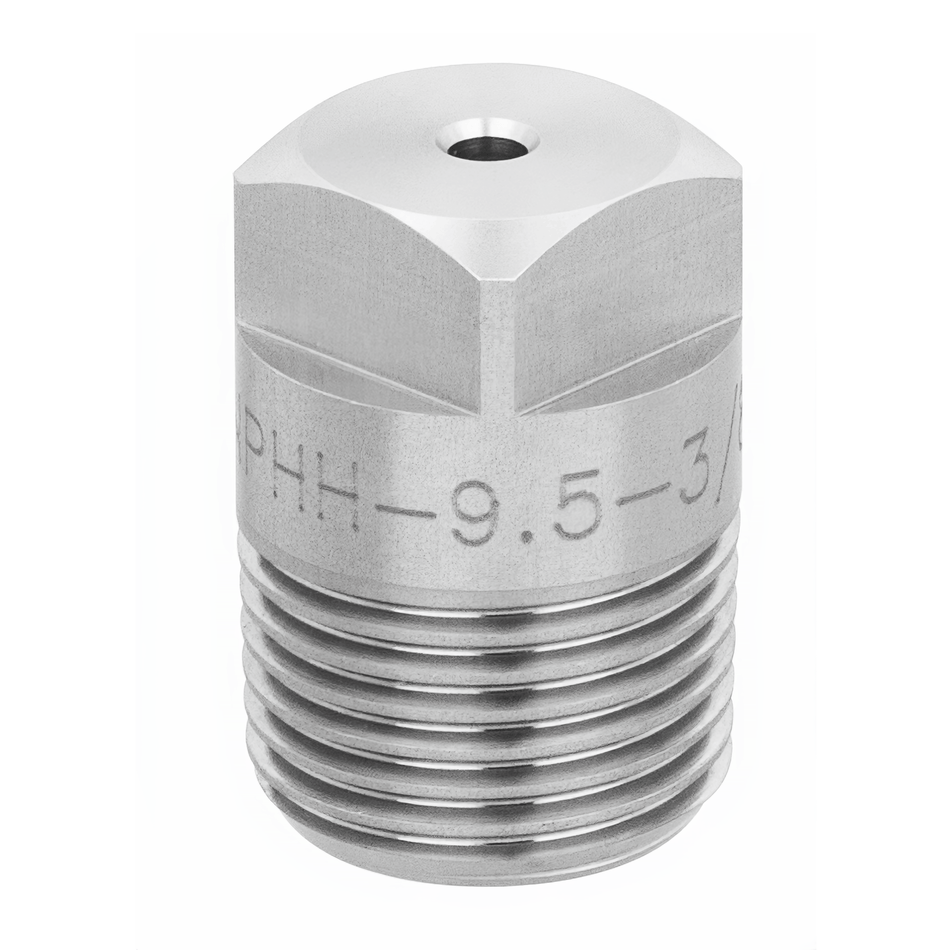

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 90 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

Inside the steel & metals line's cooling & quenching stage, a production technician relies on the NPHSJ-90470-1 to deliver a consistent full cone spray essential for even temperature reduction. Constructed from brass, this spiral nozzle maintains its corrosion resistance despite harsh operating conditions, ensuring longevity and reliable performance. The technician calibrates the nozzle's 1 inlet to achieve uniform coverage, which directly impacts the quality and structural integrity of the metal being processed. The precise spray pattern supports controlled cooling rates that are critical to the metallurgical outcomes.

Applications

The NPHSJ-90470-1 is utilized for cooling & quenching operations where maintaining precise thermal control reduces defects and improves material properties downstream. Additionally, it supports cleaning & washing processes by providing uniform spray distribution necessary for effective removal of contaminants without damaging delicate surfaces.

Industries

This nozzle is favored in industries such as building materials, chemical processing, and Energy due to its resilience in corrosive environments and ability to maintain consistent spray patterns under varied flow conditions. Mining, breweries & wineries, and manufacturing & assembly sectors also benefit from its durability and performance in demanding cleaning and cooling tasks.