Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Teflon |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 90 |

| Max. Free Passage Dia. (mm) | 6.4 |

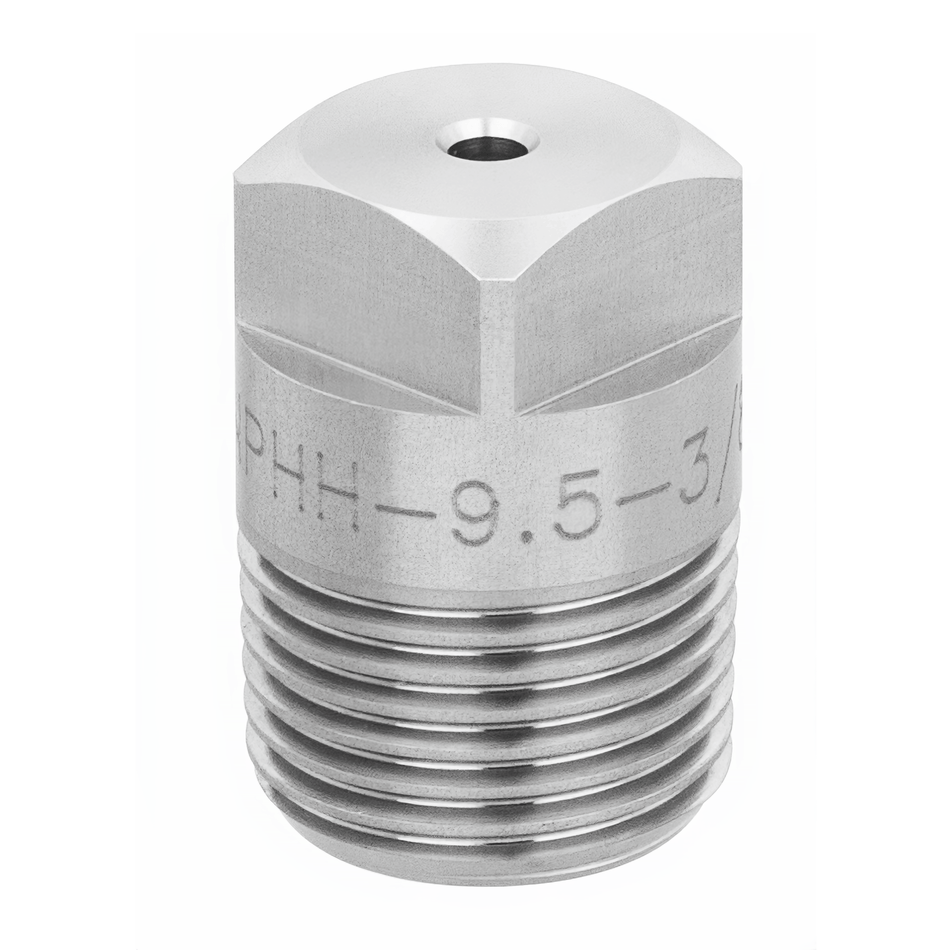

Description

Product Overview

A plant operator in the cement facility uses the NPHSJ-90340-1-TEF during cooling & quenching to maintain consistent temperature control of heated materials. Constructed from corrosion-resistant Teflon, this full cone, spiral nozzle provides a uniform spray pattern that enhances heat dissipation while minimizing chemical wear. The single inlet design allows for straightforward integration into existing piping systems, ensuring reliable operation under demanding conditions. By delivering precise fluid coverage, the nozzle helps improve process stability and extends equipment life.

Applications

In cooling & quenching operations, the NPHSJ-90340-1-TEF supports effective temperature regulation, reducing thermal stress on equipment and materials. Additionally, its performance in cleaning & washing tasks contributes to maintaining plant hygiene and operational efficiency by removing residues and preventing buildup.

Industries

This nozzle is favored in industries such as building materials, chemical processing, and Energy for its resistance to corrosive substances and ability to provide consistent spray coverage. Mining, steel & metals, and dairy sectors also rely on its durability and uniform application to meet their rigorous process requirements.