Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Polyvinyl chloride |

| Orifice Diameter. Nom. (mm) | 15.9 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 90 |

| Max. Free Passage Dia. (mm) | 6.4 |

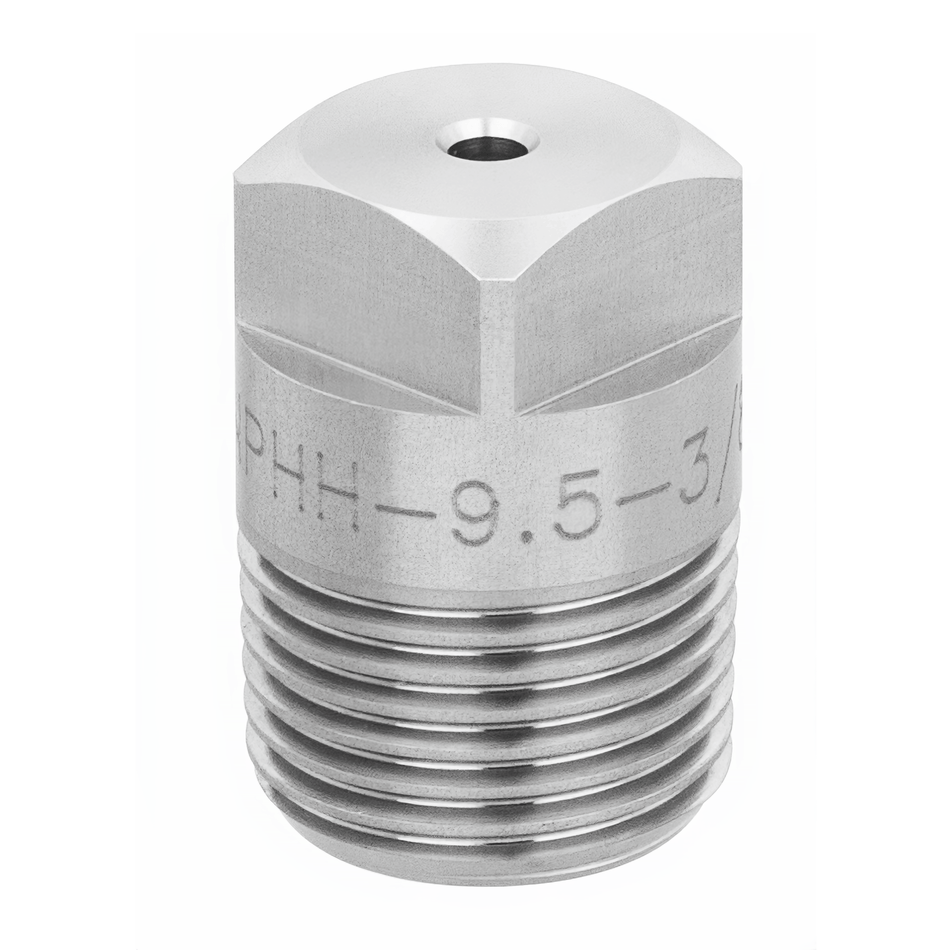

Description

Product Overview

Inside the mining line's cooling & quenching stage, a maintenance supervisor relies on the NPHSJ-90340-1-PVC to deliver consistent fluid distribution that protects critical components from thermal stress. Constructed from polyvinyl chloride, this nozzle withstands corrosive environments common in mineral processing. Its precision full cone, spiral spray pattern ensures even coverage, reducing the risk of hotspots and equipment wear. By maintaining uniform spray, operators achieve stable cooling rates that support continuous production cycles.

Applications

This nozzle supports cleaning & washing operations by uniformly applying fluids that remove residues without damaging surfaces. In cooling & quenching scenarios, it helps regulate temperature effectively, which minimizes thermal deformation and extends equipment lifespan.

Industries

Sectors such as building materials, chemical processing, Energy, mining, steel & metals, and breweries & wineries utilize the NPHSJ-90340-1-PVC due to its corrosion resistance and consistent spray performance. These industries depend on reliable nozzles to maintain process stability and product quality under harsh operating conditions.