Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 82 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 7.9 |

| Orifice Diameter. Nom. (in) | 0.313 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 60.3 |

| Length (in) | 1.875 |

| Hex Size (mm) | 17.5 |

| Hex Size (in) | 11/16 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

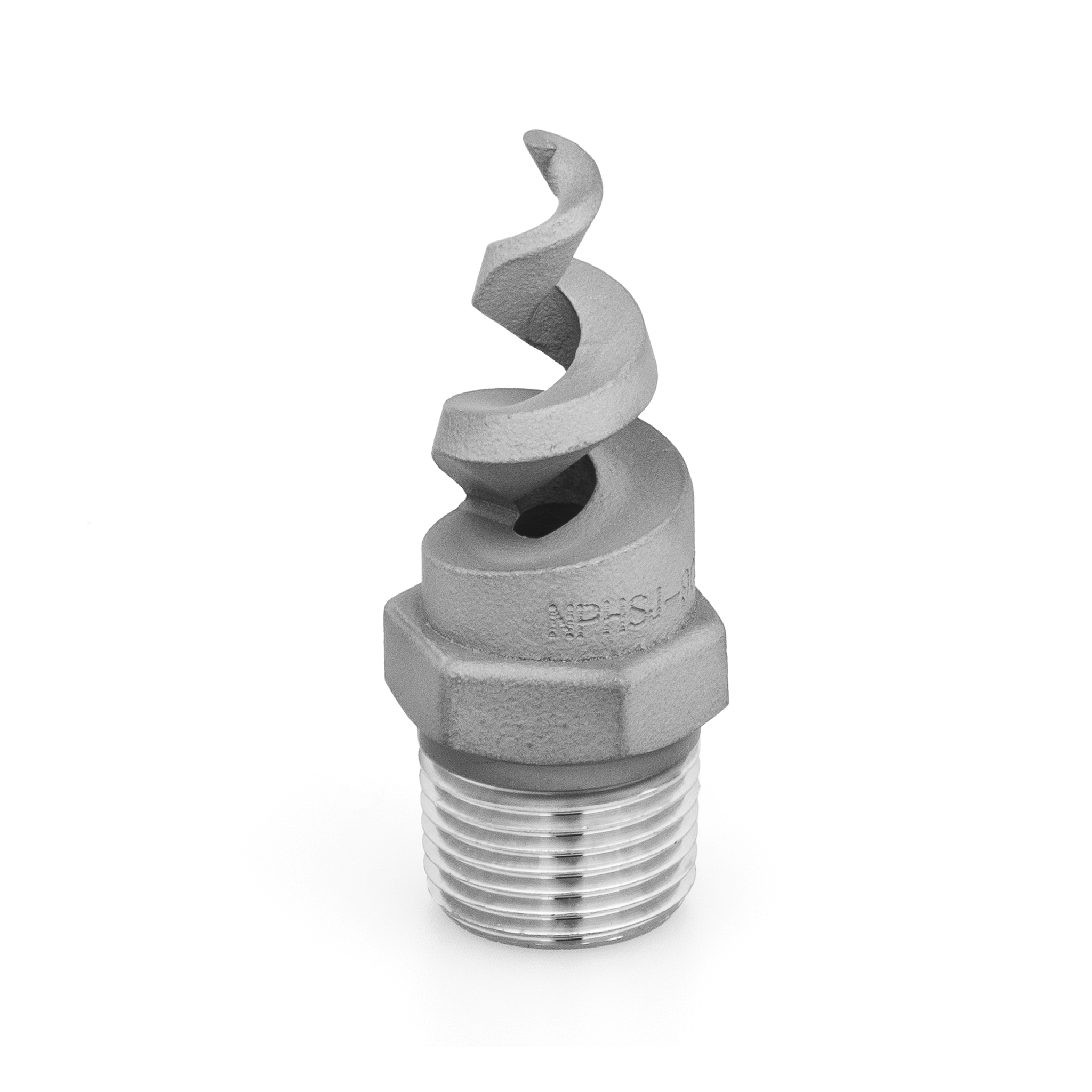

Inside the chemical processing line's cleaning & washing stage, a production technician relies on the NPHSJ-6082-3/8-316 to deliver consistent and controlled fluid distribution. Constructed from 316L stainless steel, this nozzle withstands corrosive environments while maintaining its structural integrity. The full cone, spiral spray pattern ensures an even coverage area, optimizing cleaning efficiency and reducing downtime caused by uneven spray. By precisely applying fluid at a 3/8-inch inlet, operators achieve reliable process outcomes with minimal maintenance.

Applications

In cleaning & washing processes, the uniform spray from this nozzle directly impacts the thorough removal of residues and contaminants, supporting downstream product quality and equipment longevity. Its ability to maintain consistent performance under varying conditions also benefits dust & pollution control systems by effectively suppressing airborne particles.

Industries

Sectors such as building materials, chemical processing, and mining select this nozzle for its corrosion resistance and consistent spray patterns that meet rigorous operational demands. Additionally, industries like steel & metals, breweries & wineries, and cement rely on its durability and precision to support processes ranging from cooling & quenching to specialty applications.