Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 640 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 22.2 |

| Orifice Diameter. Nom. (in) | 0.875 |

| Inlet Connection Size (in.) | 1-1/2 |

| Length (mm) | 171 |

| Length (in) | 4.375 |

| Hex Size (mm) | 50.8 |

| Hex Size (in) | 2 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 7.9 |

Description

Product Overview

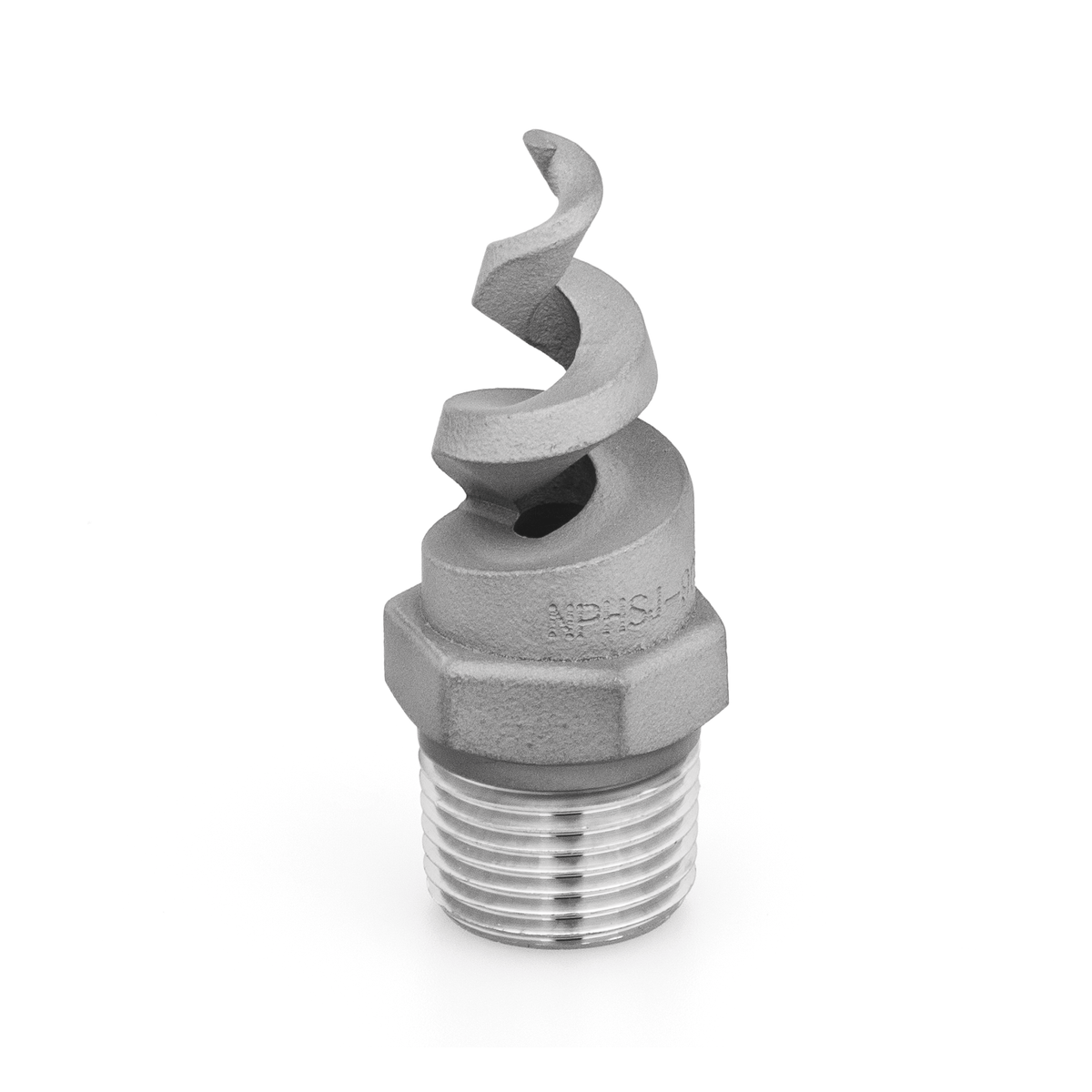

When breweries & wineries crews manage specialty applications, the NPHSJ-60640-1-1/2-316 lets each production technician achieve consistent fluid distribution through its precision full cone, spiral design. Fabricated from 316L stainless steel, this nozzle resists corrosion in harsh environments, ensuring durability during extended operation. Operators rely on the 1-1/2 inch inlet for easy integration with existing piping systems, optimizing spray coverage and minimizing downtime. The uniform spray pattern contributes to precise application rates, improving process efficiency and product quality.

Applications

In cooling & quenching scenarios, the NPHSJ-60640-1-1/2-316 maintains stable temperature control by delivering a finely atomized, uniform spray. Its role in dust & pollution control helps reduce airborne particulates, supporting compliance with environmental regulations and enhancing workplace safety.

Industries

Building materials, chemical processing, and steel & metals sectors frequently select this nozzle for its corrosion resistance and consistent spray characteristics. Energy, mining, and manufacturing & assembly operations also depend on the NPHSJ-60640-1-1/2-316 for reliable performance in both routine cleaning & washing and specialized production phases.