Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

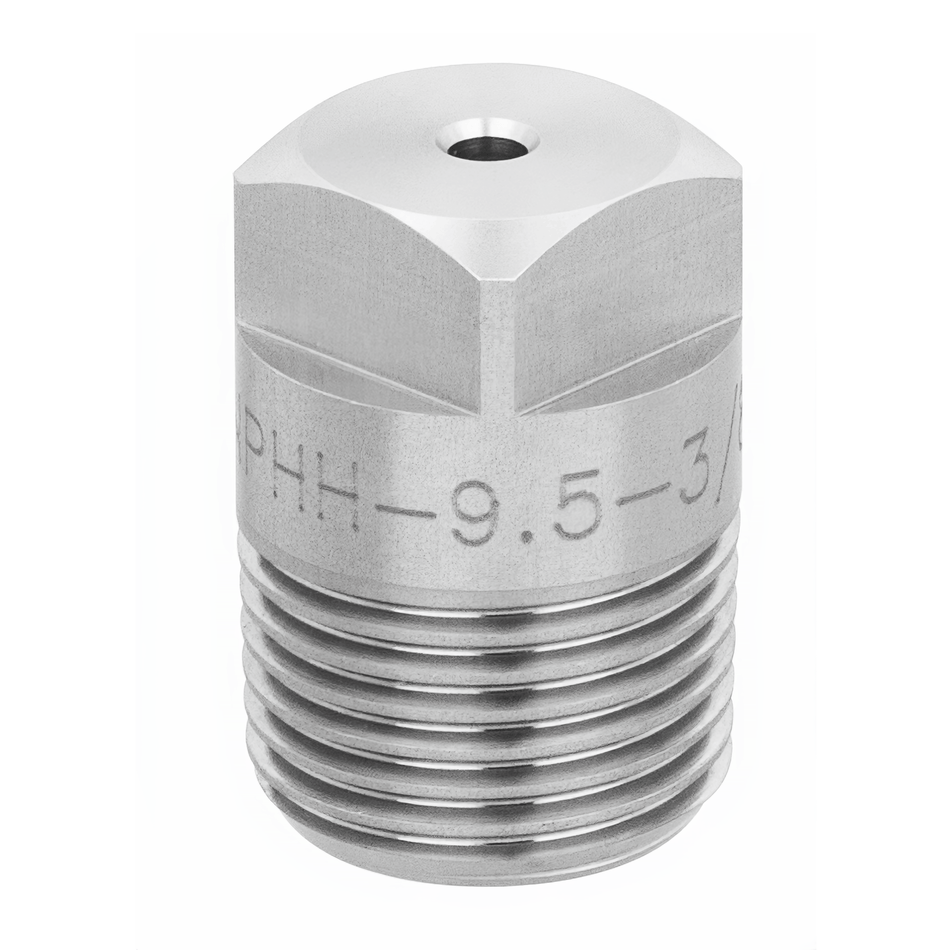

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Polyvinyl chloride |

| Orifice Diameter. Nom. (mm) | 15.9 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

Inside the building materials line's fire protection & safety stage, a quality manager relies on the NPHSJ-60340-1-PVC to deliver consistent full cone spray coverage. Constructed from polyvinyl chloride, this nozzle resists corrosion in harsh chemical environments while maintaining precise spiral atomization. Operators calibrate the nozzle to ensure uniform droplets are distributed across critical areas, improving system reliability and reducing downtime associated with uneven spray patterns. The durable design supports long service intervals even under continuous operation.

Applications

In fire protection & safety systems, the uniform spray generated by the NPHSJ-60340-1-PVC contributes to dependable flame suppression and temperature control. Additionally, its corrosion-resistant properties make it suitable for dust & pollution control applications where chemical exposure and particulate buildup are common challenges.

Industries

Sectors such as building materials, chemical processing, mining, and steel & metals rely on this nozzle for its balance of durability and spray precision. Breweries & wineries and dairy operations also benefit from its corrosion resistance and consistent coverage during manufacturing & assembly processes where contamination control is essential.