Product Parameters

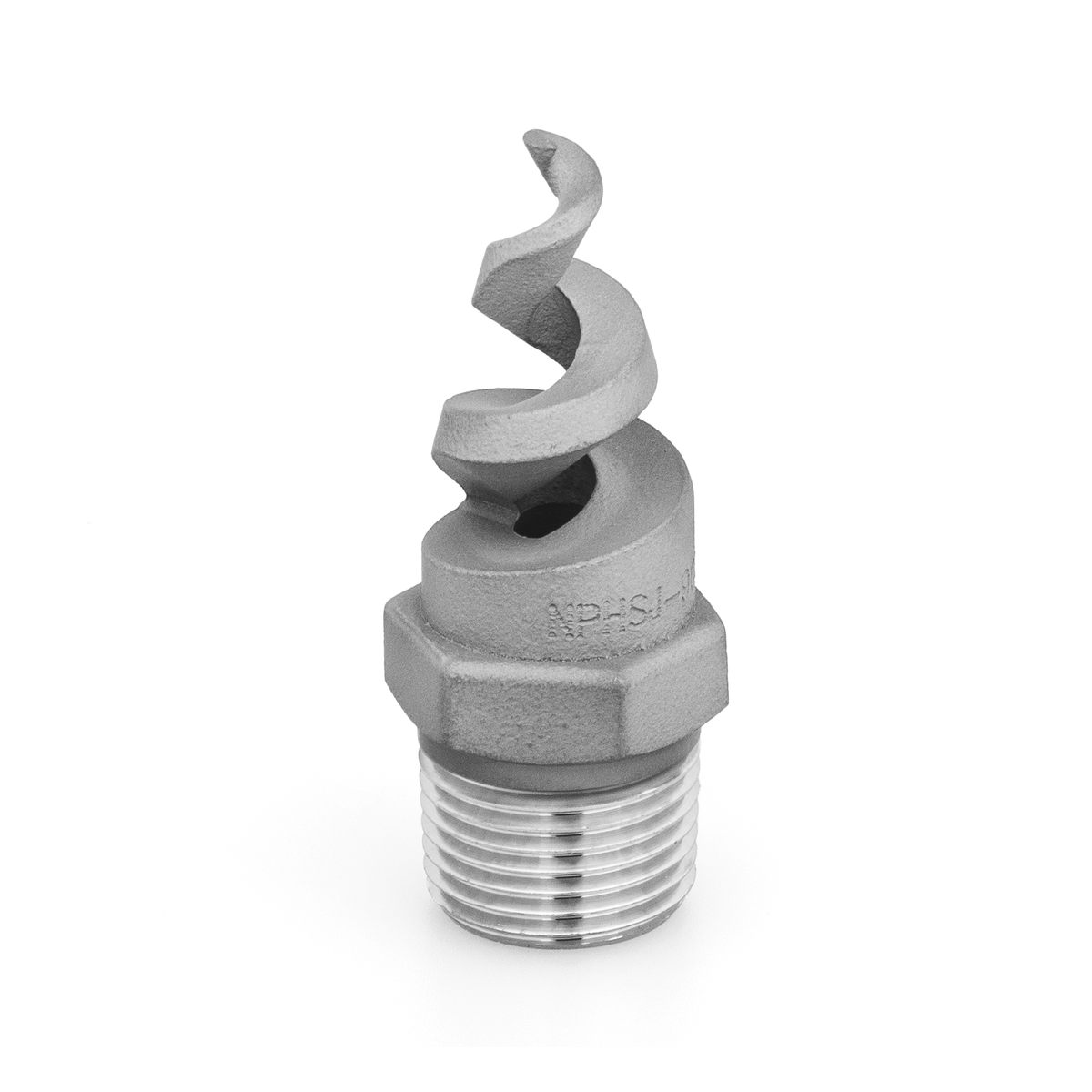

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 30 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4.8 |

| Orifice Diameter. Nom. (in) | 0.188 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 60.3 |

| Length (in) | 1.875 |

| Hex Size (mm) | 17.5 |

| Hex Size (in) | 11/16 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

Inside the cement line's specialty applications stage, a utilities coordinator relies on the NPHSJ-6030-3/8-316 to deliver consistent coverage through its full cone, spiral spray pattern. Constructed from 316L stainless steel, the nozzle resists corrosion caused by abrasive dust and moisture in the plant environment. By maintaining a uniform spray distribution from its 3/8-inch inlet, the nozzle supports efficient dust suppression and process cooling, directly contributing to operational stability and equipment longevity. The coordinator monitors flow rates and spray angles to ensure the nozzle meets precise process parameters.

Applications

In cleaning & washing operations within industrial facilities, the nozzle's uniform full cone spray enhances the removal of particulate buildup and surface contaminants. This consistency also benefits dust & pollution control processes, reducing airborne particulates and improving air quality downstream of the application point.

Industries

The NPHSJ-6030-3/8-316 is commonly deployed across building materials, chemical processing, and Energy sectors where corrosion resistance and reliable spray performance are critical. Additionally, industries such as mining, steel & metals, breweries & wineries, cement, dairy, and manufacturing & assembly depend on this nozzle to maintain process efficiency under harsh operating conditions.