Product Parameters

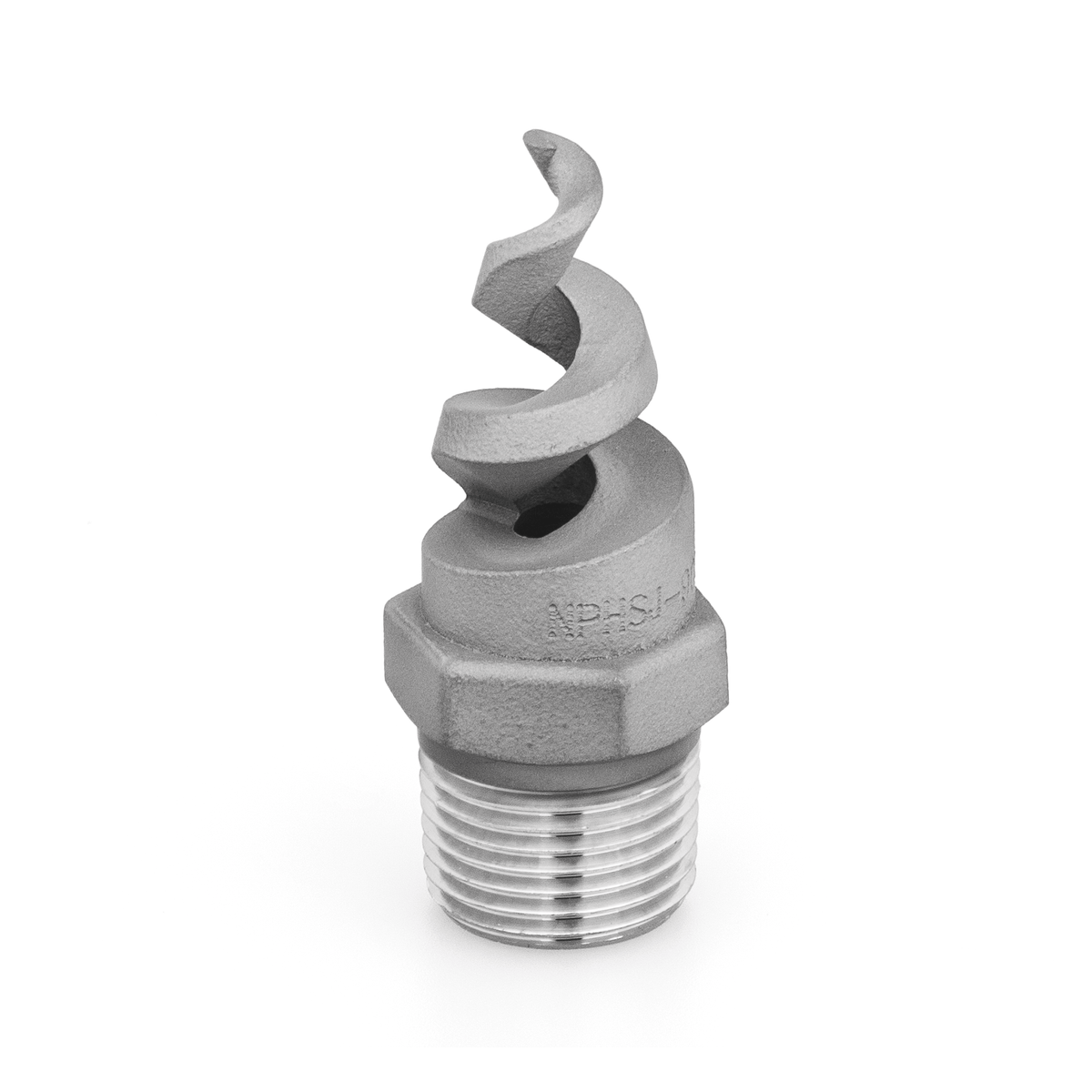

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 120 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 9.5 |

| Orifice Diameter. Nom. (in) | 0.375 |

| Inlet Connection Size (in.) | 1/2 |

| Length (mm) | 79.4 |

| Length (in) | 2.500 |

| Hex Size (mm) | 22.2 |

| Hex Size (in) | 7/8 |

| Spray Angle at Rated Pressure (PSI) | 60 |

| Max. Free Passage Dia. (mm) | 4.8 |

Description

Product Overview

A quality manager in the chemical processing facility uses the NPHSJ-60120-1/2-316 during specialty applications to ensure consistent spray distribution across reactor surfaces. Constructed from 316L stainless steel, this spiral nozzle delivers a precise full cone spray pattern that resists corrosion in harsh chemical environments. By maintaining uniform coverage, it helps optimize reaction efficiency while minimizing downtime caused by nozzle wear or clogging. The 1/2 inch inlet design facilitates easy integration with existing piping systems, supporting reliable process control.

Applications

In cleaning & washing operations, the NPHSJ-60120-1/2-316 provides consistent spray coverage to remove residues without damaging equipment surfaces. Its ability to deliver uniform cooling & quenching also helps stabilize thermal processes, reducing material stress and improving overall product quality.

Industries

The NPHSJ-60120-1/2-316 is favored in industries such as building materials, chemical processing, and Energy due to its corrosion resistance and precision spray control. Mining, steel & metals, breweries & wineries, cement, dairy, and manufacturing & assembly sectors benefit from its durability and consistent performance in demanding production environments.