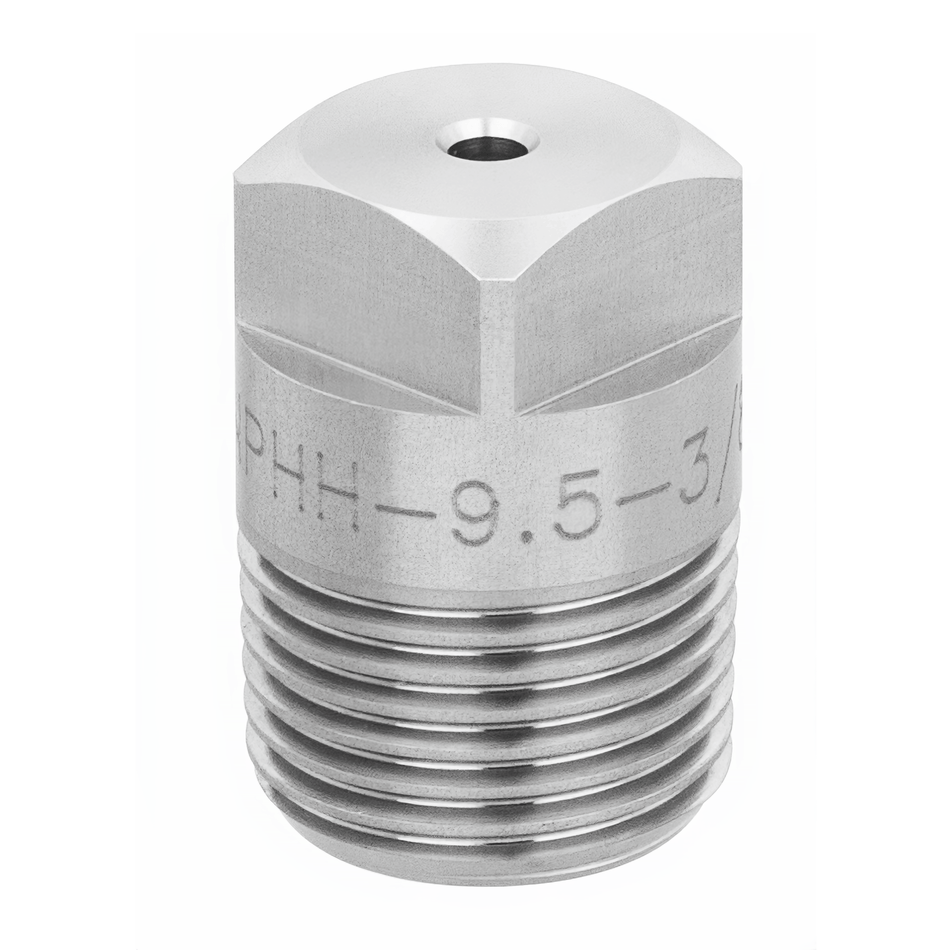

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 170 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

During cooling & quenching on a mining site, maintenance supervisors trust the NPHSJ-170470-1 to deliver consistent and precise spray coverage. This brass nozzle features a full cone, spiral design that ensures uniform fluid distribution over metals being cooled, reducing thermal stress and improving process reliability. Its corrosion-resistant construction extends service life in harsh environments, minimizing downtime associated with nozzle replacement. Operators value its 1-inch inlet fit for easy integration into existing spray systems.

Applications

In cooling & quenching applications, the NPHSJ-170470-1 provides steady, even spray patterns that help maintain optimal temperature control and material integrity. Additionally, its effectiveness in dust & pollution control supports safer working conditions by suppressing airborne particulates near processing areas.

Industries

The NPHSJ-170470-1 is widely utilized across building materials, chemical processing, and steel & metals industries due to its durability and reliable spray performance. Energy, mining, and breweries & wineries sectors also employ this nozzle where controlled fluid application and corrosion resistance are critical to operational efficiency.