Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Teflon |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 170 |

| Max. Free Passage Dia. (mm) | 6.4 |

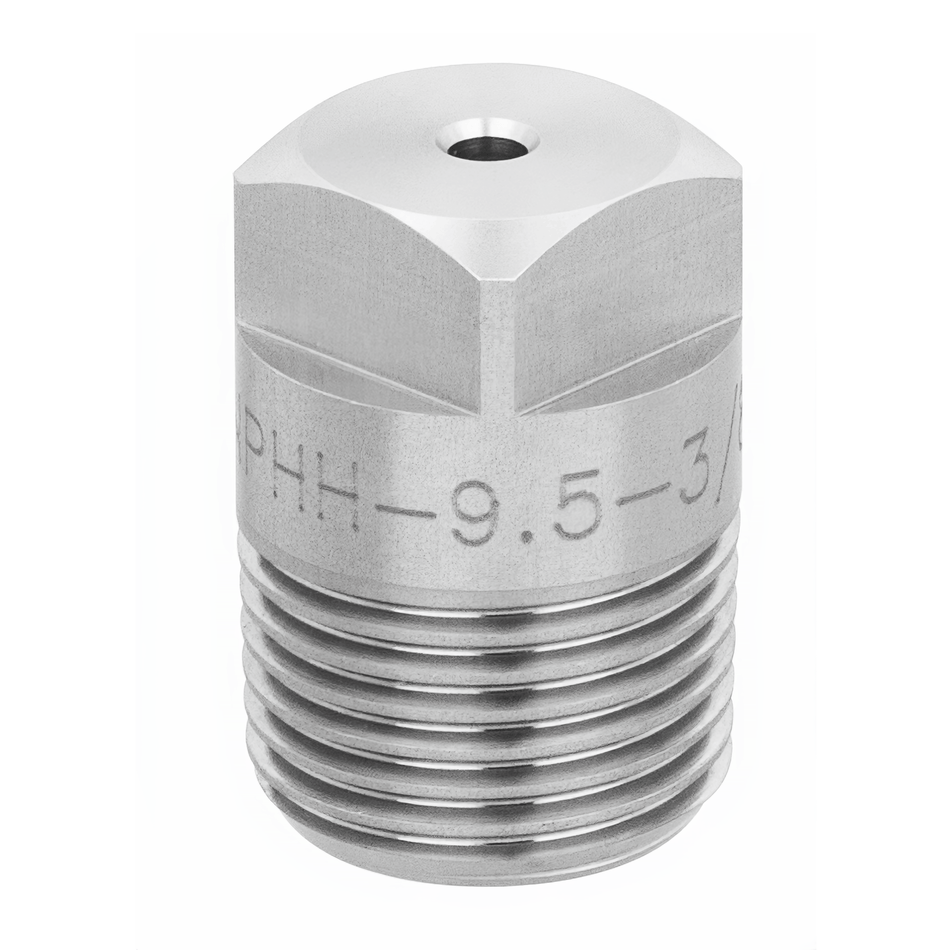

Description

Product Overview

During specialty applications on a mining site, maintenance supervisors trust the NPHSJ-170340-1-TEF to deliver consistent spray coverage critical for dust suppression and equipment cooling. Constructed from corrosion-resistant teflon, this nozzle withstands harsh chemicals and abrasive environments while maintaining a full cone, spiral spray pattern. Operators rely on the uniform distribution to reduce downtime and extend the life of surrounding components. The NPHSJ-170340-1-TEF's precise flow control ensures efficient fluid use without sacrificing performance.

Applications

In dust & pollution control scenarios, this nozzle provides an even spray that effectively captures and settles airborne particles, improving air quality and safety conditions on site. Its use in cooling & quenching processes supports thermal regulation of machinery, enabling reliable operation under continuous load.

Industries

The NPHSJ-170340-1-TEF finds application across building materials, chemical processing, and mining industries where resistance to corrosive substances and durable spray patterns are essential. Sectors such as steel & metals, breweries & wineries, and cement also leverage this nozzle to maintain consistent process control and minimize maintenance challenges.