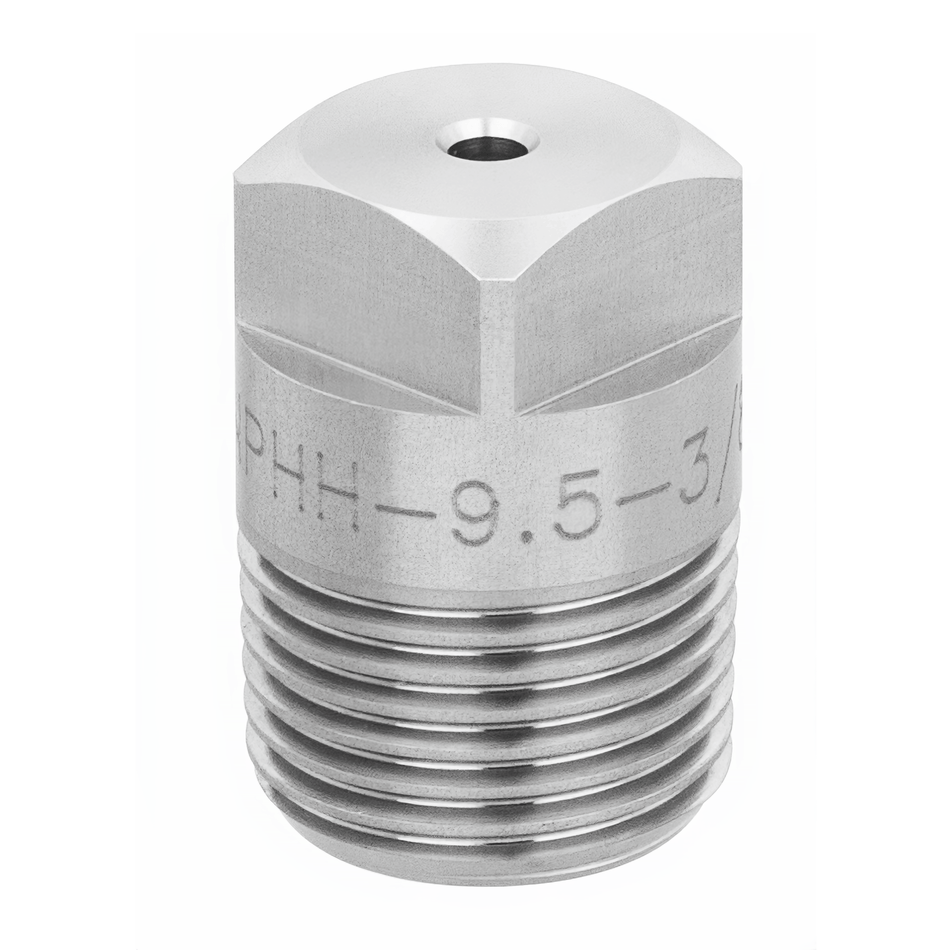

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Polypropylene |

| Orifice Diameter. Nom. (mm) | 15.9 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 170 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

During cooling & quenching on a breweries & wineries site, quality managers trust the NPHSJ-170340-1-PP to deliver consistent full cone coverage critical for process stability. Constructed from polypropylene, this nozzle resists corrosion from acidic cleaning agents commonly used in the facility. Its spiral design produces a uniform spray pattern that enhances cooling efficiency while minimizing overspray. Operators rely on the NPHSJ-170340-1-PP to maintain precise flow rates, ensuring predictable downstream results in temperature control.

Applications

In cleaning & washing operations, the nozzle's full cone spray pattern effectively removes residues without damaging sensitive surfaces. Its role in dust & pollution control supports compliance with environmental standards by suppressing airborne particulates during material handling.

Industries

Sectors such as chemical processing, cement production, and steel & metals benefit from the NPHSJ-170340-1-PP's corrosion resistance and spray uniformity under demanding conditions. Additionally, manufacturing & assembly plants and mining operations favor this nozzle for its durability and consistent performance during cooling and washing cycles.