Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

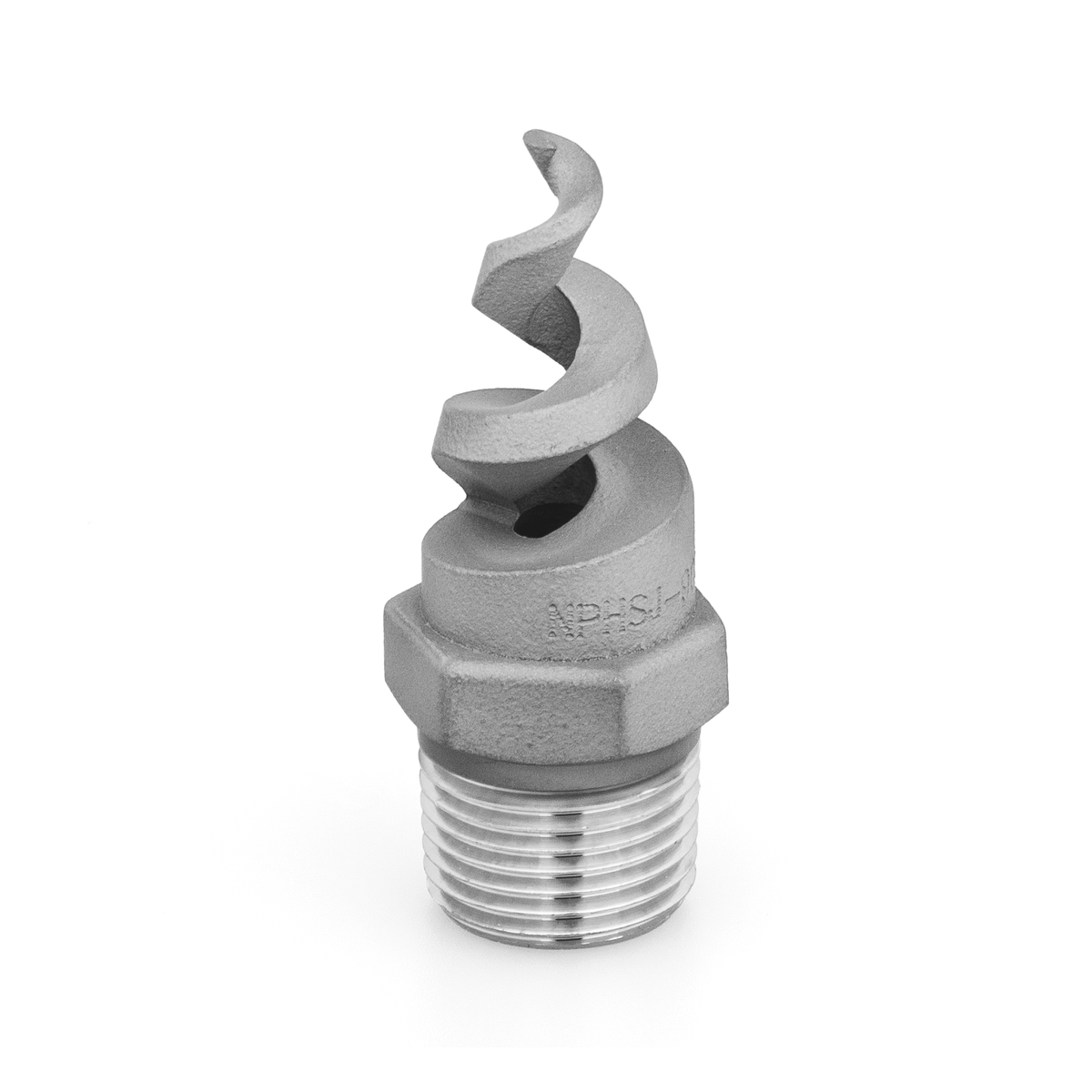

| Product Series | NPHSJ |

| Capacity Size | 1400 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 34.9 |

| Orifice Diameter. Nom. (in) | 1.375 |

| Inlet Connection Size (in.) | 2 |

| Length (mm) | 175 |

| Length (in) | 6.875 |

| Hex Size (mm) | 63.5 |

| Hex Size (in) | 2-1/2 |

| Spray Angle at Rated Pressure (PSI) | 170 |

| Max. Free Passage Dia. (mm) | 11.1 |

Description

Product Overview

A production technician in the manufacturing & assembly facility uses the NPHSJ-1701400-2-316 during fire protection & safety to deliver a consistent full cone spray that enhances coverage and efficiency. The nozzle's 316L stainless steel construction withstands corrosive environments, ensuring long-term reliability in demanding conditions. By adjusting the flow rate through its 2 inlet design, the operator achieves uniform liquid distribution essential for maintaining system integrity and compliance with safety protocols. This precision spiral nozzle supports controlled application, minimizing overspray and optimizing resource use.

Applications

In cleaning & washing operations, the NPHSJ-1701400-2-316 provides even coverage that improves residue removal and reduces downtime for equipment maintenance. Its role in dust & pollution control helps limit particulate emissions by generating a consistent spray pattern that captures airborne contaminants before they disperse.

Industries

Sectors such as building materials, chemical processing, and steel & metals rely on this nozzle for its corrosion resistance and precise spray control under harsh operating conditions. The brewing and dairy industries also benefit from its reliable performance in cleaning and cooling tasks, while mining and cement operations use it to manage dust and cooling processes effectively.