Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Polyvinyl chloride |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 150 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

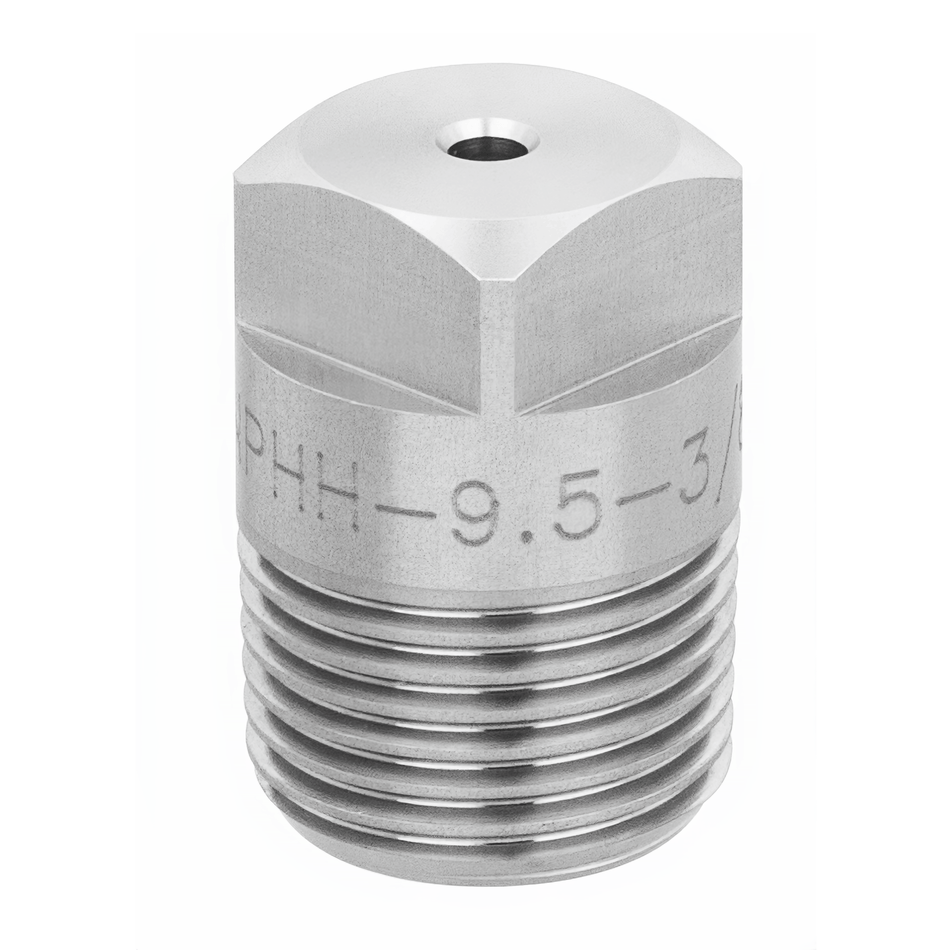

Inside the chemical processing line's specialty applications stage, a maintenance supervisor relies on the NPHSJ-150470-1-PVC to deliver consistent coverage and corrosion resistance. Constructed from polyvinyl chloride, this nozzle features a full cone, spiral spray pattern that ensures uniform distribution of fluids across the target area. When installed, the device maintains stable flow rates through its single inlet design, supporting process reliability. Operators observe improved system efficiency and reduced downtime due to the nozzle's durable material and precise spray control.

Applications

The NPHSJ-150470-1-PVC plays a crucial role in cleaning & washing operations by providing thorough surface contact and minimizing residue build-up. Its uniform spray pattern also enhances dust & pollution control efforts by effectively capturing airborne particles during processing.

Industries

This nozzle is frequently utilized across building materials, chemical processing, Energy, mining, steel & metals, breweries & wineries, cement, dairy, and manufacturing & assembly sectors. Its resistance to corrosion and ability to generate consistent spray patterns make it suitable for the varied demands of these industrial environments.