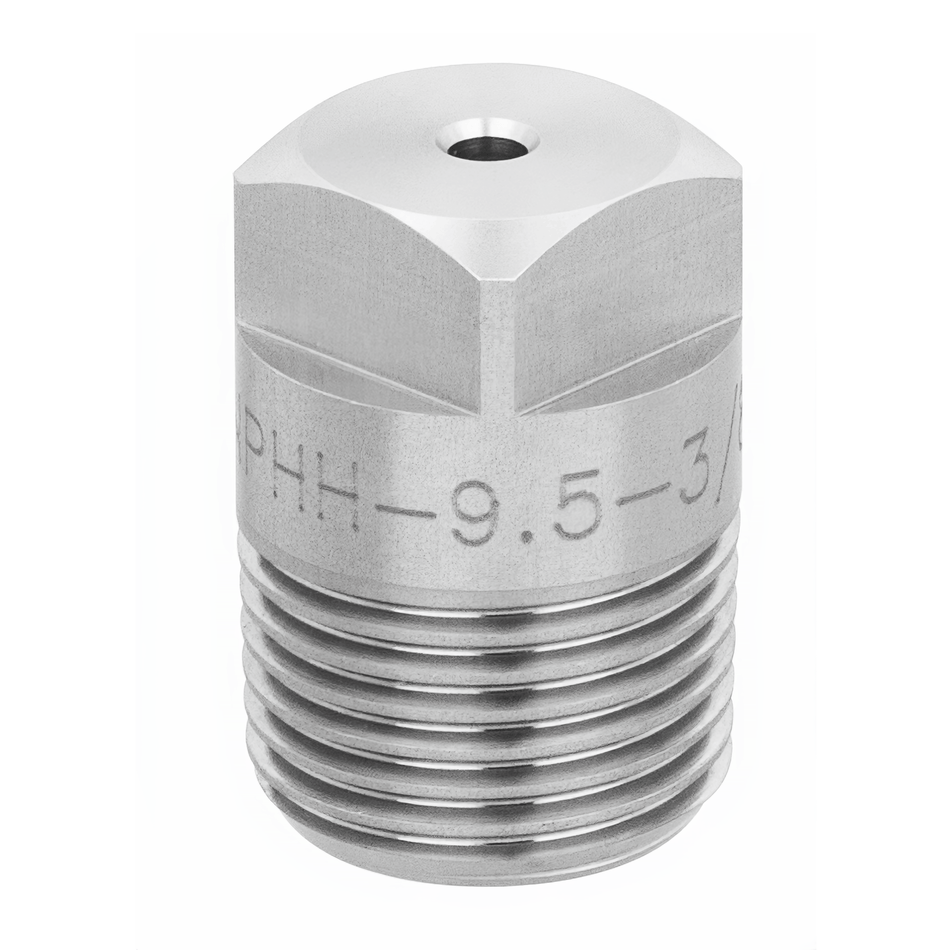

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 470 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.75 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 150 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

A plant operator in the cement facility uses the NPHSJ-150470-1 during cleaning & washing to maintain equipment surfaces by applying a consistent full cone spray pattern. Constructed from brass, the nozzle resists corrosion from harsh chemicals and abrasive particles encountered on-site. The uniform distribution of the spiral spray ensures minimal downtime by effectively removing dust and residues without damaging sensitive components. This controlled spray improves overall operational efficiency and extends the lifespan of processing machinery.

Applications

In cleaning & washing operations, the NPHSJ-150470-1 delivers uniform coverage that reduces buildup and contamination on critical surfaces, supporting smoother process flows. Additionally, its precise spray characteristics contribute to dust & pollution control by suppressing airborne particulates, enhancing workplace safety and compliance with environmental regulations.

Industries

The nozzle is widely utilized across building materials, chemical processing, Energy, mining, steel & metals, breweries & wineries, cement, dairy, and manufacturing & assembly sectors due to its durability and consistent spray performance. These industries benefit from the nozzle's ability to withstand corrosive environments while providing reliable fluid distribution necessary for their varied process requirements.