Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Teflon |

| Orifice Diameter. Nom. (mm) | 19.1 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 150 |

| Max. Free Passage Dia. (mm) | 6.4 |

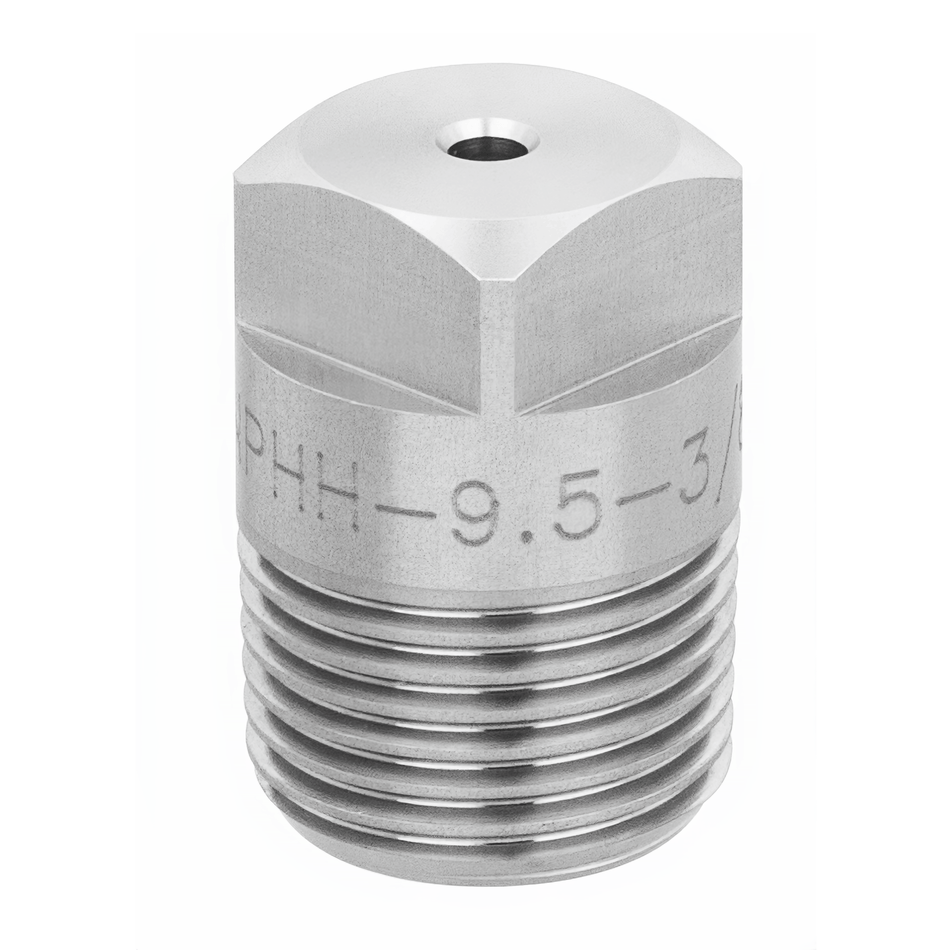

Description

Product Overview

Inside the breweries & wineries line's specialty applications stage, a quality manager relies on the NPHSJ-150340-1-TEF to deliver consistent and uniform spray coverage during critical cleaning cycles. Constructed from Teflon, the nozzle withstands aggressive chemicals, ensuring long-term corrosion resistance in harsh environments. Its full cone, spiral spray pattern optimizes fluid distribution, which enhances process reliability and reduces downtime. Operators measure the nozzle's performance through flow consistency and spray uniformity, directly impacting product quality and equipment maintenance schedules.

Applications

The NPHSJ-150340-1-TEF is frequently employed in cleaning & washing processes where precise fluid application is necessary to remove residues without damaging sensitive surfaces. Additionally, its uniform spray aids cooling & quenching operations by providing controlled temperature reduction, which improves material properties and operational safety.

Industries

This nozzle is favored across diverse sectors such as building materials, chemical processing, and mining, where corrosion resistance and spray precision are critical. Energy, steel & metals, breweries & wineries, cement, dairy, and manufacturing & assembly industries rely on the NPHSJ-150340-1-TEF to maintain consistent process conditions and extend service intervals under demanding conditions.