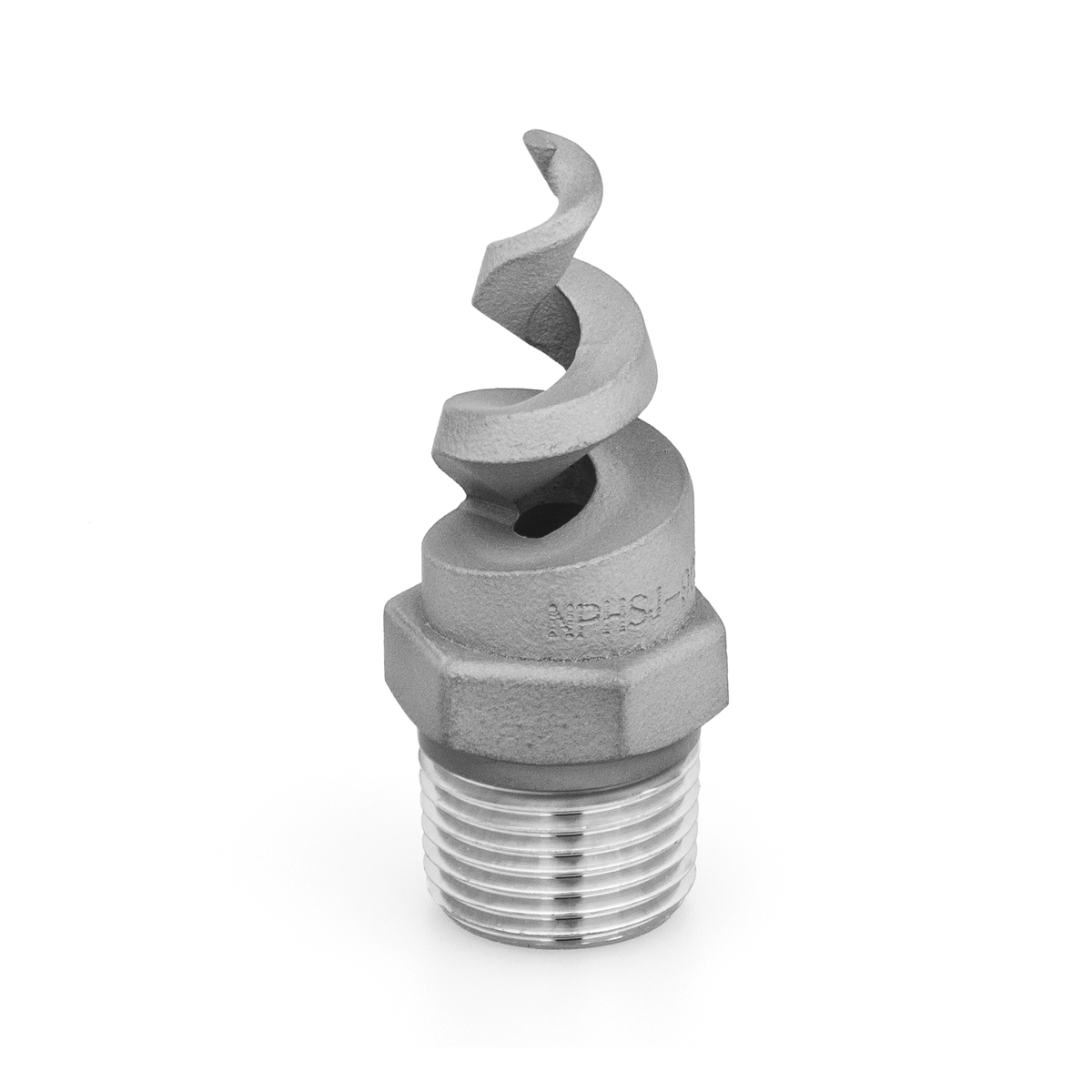

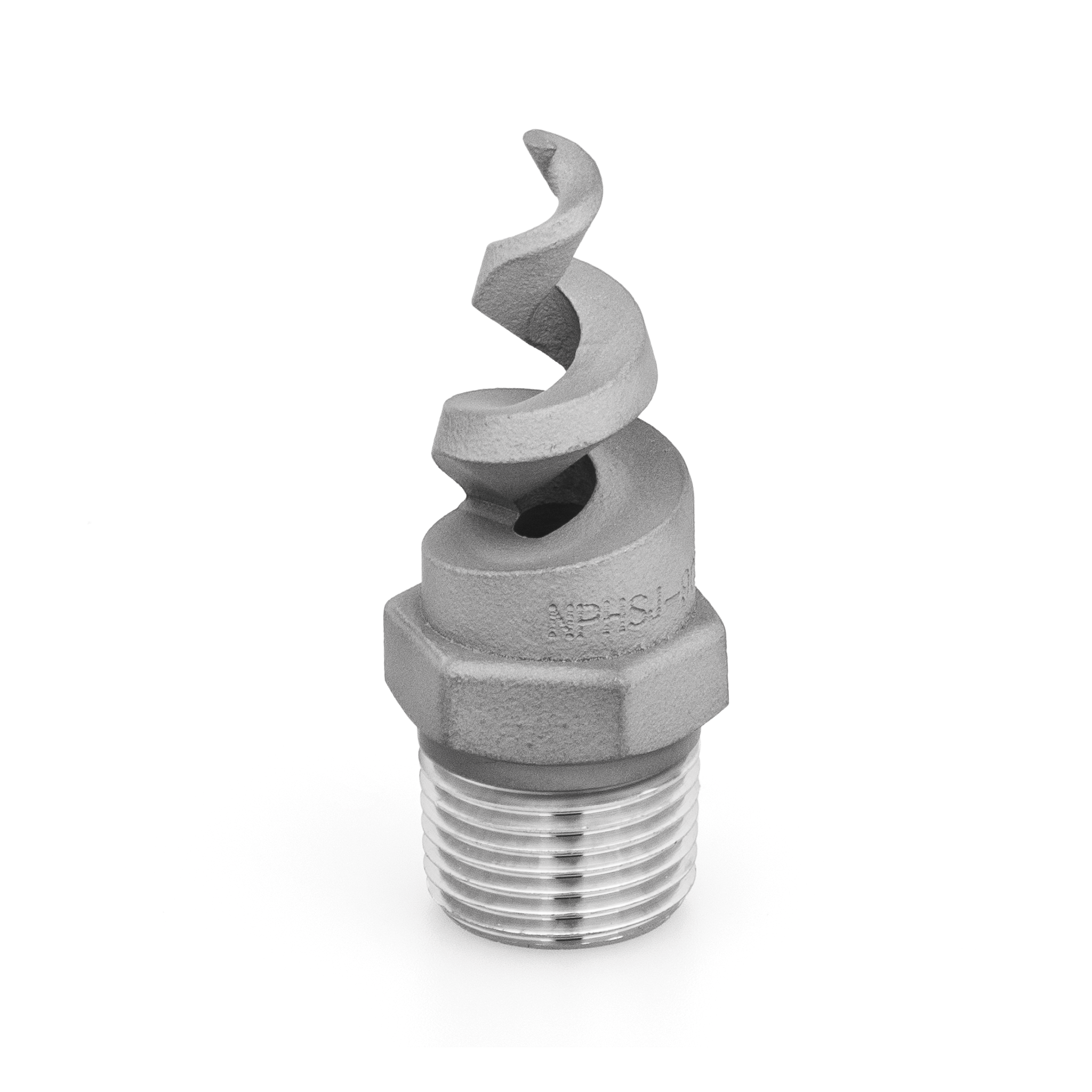

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 120 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 9.5 |

| Orifice Diameter. Nom. (in) | 0.375 |

| Inlet Connection Size (in.) | 1/2 |

| Length (mm) | 79.4 |

| Length (in) | 2.500 |

| Hex Size (mm) | 22.2 |

| Hex Size (in) | 7/8 |

| Spray Angle at Rated Pressure (PSI) | 150 |

| Max. Free Passage Dia. (mm) | 4.8 |

Description

Product Overview

When breweries & wineries crews manage cleaning & washing, the NPHSJ-150120-1/2-316 lets each quality manager achieve consistent sanitation by delivering a uniform full cone spray pattern. Constructed from 316L stainless steel, this nozzle resists corrosion even in aggressive chemical environments. Operators rely on its 1/2 inch inlet to integrate seamlessly into existing piping systems, ensuring steady flow rates and thorough surface coverage. The precise spiral design contributes to efficient liquid distribution, minimizing downtime and verifying compliance with hygiene standards.

Applications

In cleaning & washing processes, the uniform spray of this nozzle enhances removal of residues and reduces water usage through controlled coverage. Additionally, its application in dust & pollution control supports emission reduction efforts by evenly dispersing suppressants over targeted areas.

Industries

The NPHSJ-150120-1/2-316 is favored across building materials, chemical processing, Energy, mining, and steel & metals sectors due to its durability and consistent spray characteristics. Its suitability for breweries & wineries, cement, dairy, and manufacturing & assembly facilities stems from the nozzle's ability to maintain performance under varied operational stresses.