Product Parameters

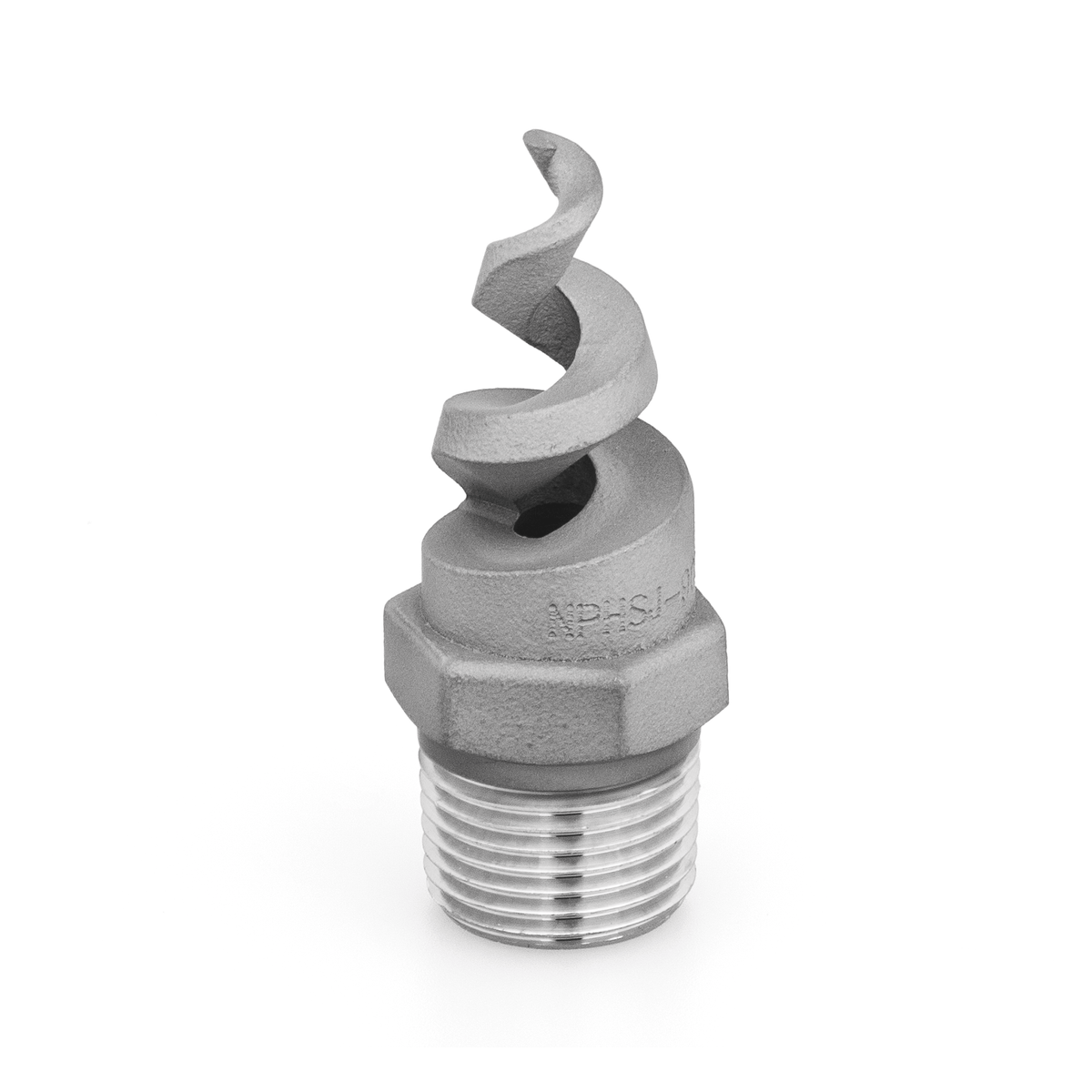

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 53 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 6.4 |

| Orifice Diameter. Nom. (in) | 0.25 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 60.3 |

| Length (in) | 1.875 |

| Hex Size (mm) | 17.5 |

| Hex Size (in) | 11/16 |

| Spray Angle at Rated Pressure (PSI) | 120 |

| Max. Free Passage Dia. (mm) | 3.2 |

Description

Product Overview

Inside the mining line's car wash stage, a quality manager relies on the NPHSJ-12053-3/8-316 to deliver consistent and uniform spray coverage critical for removing heavy debris. Constructed from 316L stainless steel, the nozzle withstands corrosive environments while maintaining its full cone, spiral spray pattern. This durability ensures reliable operation over extended service intervals and contributes to reduced maintenance downtime. The precision design of the NPHSJ-12053-3/8-316 supports efficient fluid distribution, optimizing water usage during cleaning cycles.

Applications

In the car wash process, cleaning & washing operations benefit from the nozzle's ability to provide even spray distribution, which enhances surface cleanliness and reduces residue buildup. Additionally, its performance supports dust & pollution control measures downstream by minimizing particulate emissions during wash sequences.

Industries

Sectors such as mining, building materials, and chemical processing utilize this nozzle because of its resistance to harsh chemical exposure and abrasive conditions. Energy, breweries & wineries, and steel & metals industries also depend on its reliability for processes requiring consistent spray patterns and corrosion resistance.