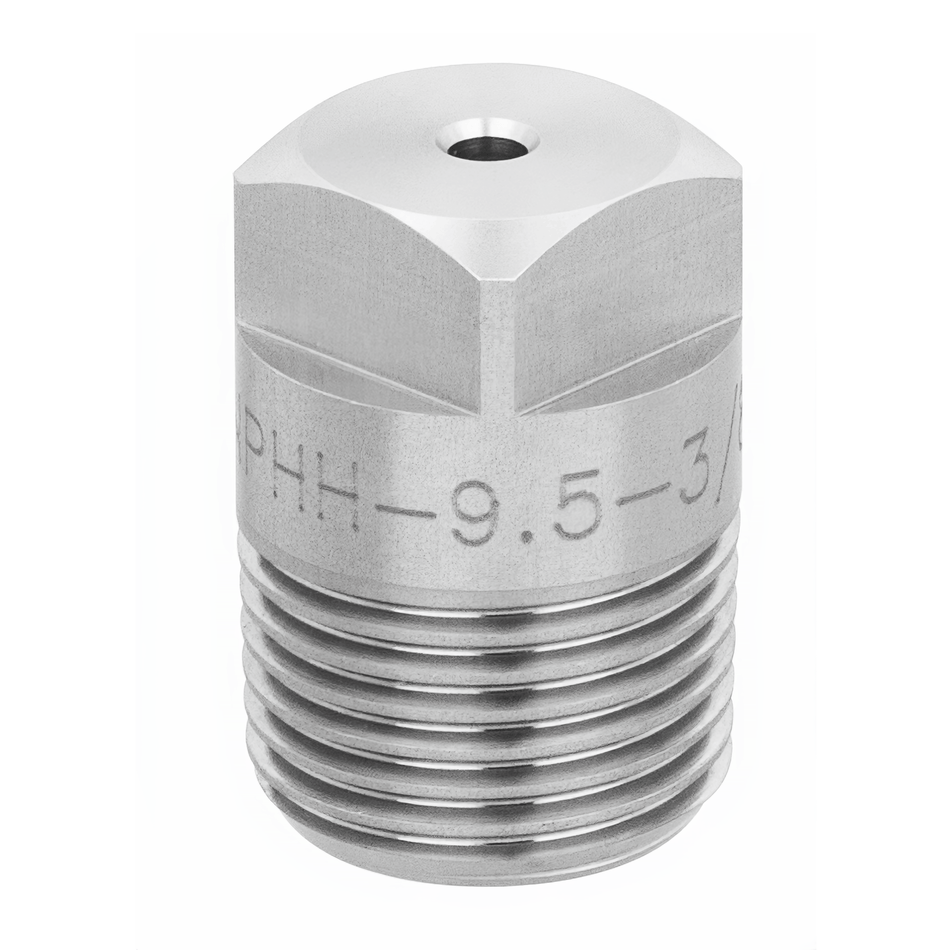

Product Parameters

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 340 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 15.9 |

| Orifice Diameter. Nom. (in) | 0.625 |

| Inlet Connection Size (in.) | 1 |

| Length (mm) | 116 |

| Length (in) | 3.625 |

| Hex Size (mm) | 34.9 |

| Hex Size (in) | 1-3/8 |

| Spray Angle at Rated Pressure (PSI) | 120 |

| Max. Free Passage Dia. (mm) | 6.4 |

Description

Product Overview

Inside the mining line's specialty applications stage, a production technician relies on the NPHSJ-120340-1 to deliver consistent coverage through its precision full cone, spiral spray pattern. Constructed from brass, the nozzle resists corrosion in harsh environments, ensuring reliable operation over extended cycles. The uniform spray distribution helps maintain controlled dust suppression and cooling, directly impacting process efficiency and safety metrics on the line. This nozzle's 1-inch inlet allows straightforward integration with existing piping systems, simplifying maintenance and replacement tasks.

Applications

In dust & pollution control, the NPHSJ-120340-1 plays a critical role by providing even spray coverage that minimizes particulate matter dispersion in mining and manufacturing settings. Its use in cleaning & washing processes further supports equipment longevity by effectively removing residues without damaging sensitive components.

Industries

Sectors such as building materials, chemical processing, and steel & metals incorporate this nozzle for its durability and spray consistency under demanding production conditions. Additionally, breweries & wineries and the dairy industry benefit from the corrosion resistance and precise liquid distribution required for their controlled processing environments.