Product Parameters

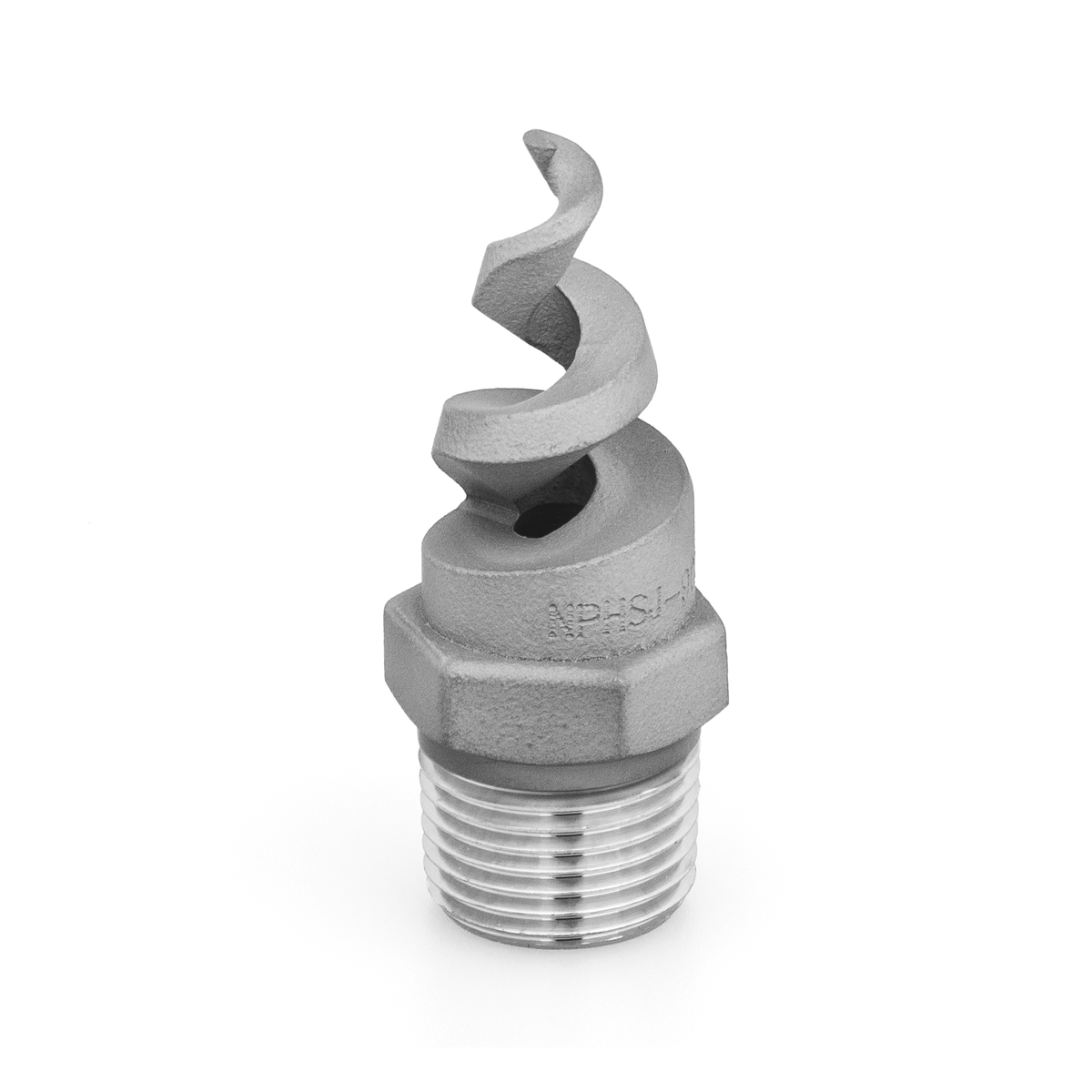

| Product Family | Full Cone Spiral |

|---|---|

| Product Series | NPHSJ |

| Capacity Size | 2560 |

| Inlet Connection Thread Type | NPT |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 44.5 |

| Orifice Diameter. Nom. (in) | 1.75 |

| Inlet Connection Size (in.) | 3 |

| Length (mm) | 302 |

| Length (in) | 8.000 |

| Hex Size (mm) | 95.3 |

| Hex Size (in) | 3-3/4 |

| Spray Angle at Rated Pressure (PSI) | 120 |

| Max. Free Passage Dia. (mm) | 14.3 |

Description

Product Overview

During cooling & quenching on a building materials site, utilities coordinators trust the NPHSJ-1202560-3-316 to deliver consistent full cone coverage with minimal variation. Constructed from 316L stainless steel, this spiral nozzle resists corrosion even under high-temperature and chemically aggressive environments. The three-inlet design ensures balanced fluid distribution, helping operators maintain uniform spray patterns essential for effective heat dissipation. Its precise flow characteristics reduce downtime by optimizing quenching efficiency and extending equipment life.

Applications

In cleaning & washing processes, the NPHSJ-1202560-3-316 enables thorough surface treatment while minimizing water and chemical usage, improving operational costs. Its role in dust & pollution control also supports regulatory compliance by generating uniform sprays that trap particulates effectively within industrial exhaust systems.

Industries

Sectors such as building materials, chemical processing, and mining favor this nozzle for its durability under harsh conditions and reliable performance in continuous operation. Additionally, steel & metals, breweries & wineries, and manufacturing & assembly facilities benefit from its corrosion-resistant properties and consistent spray distribution.