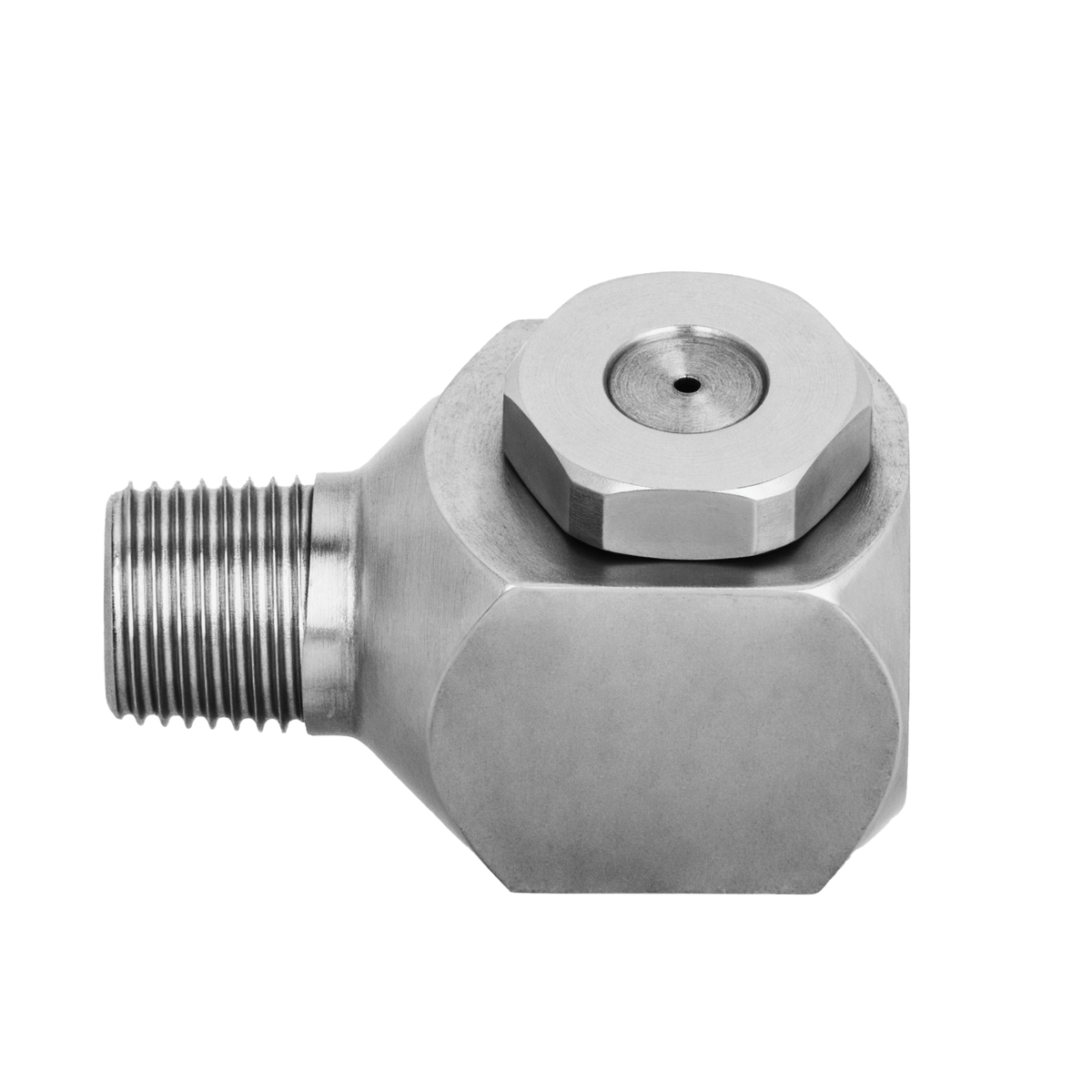

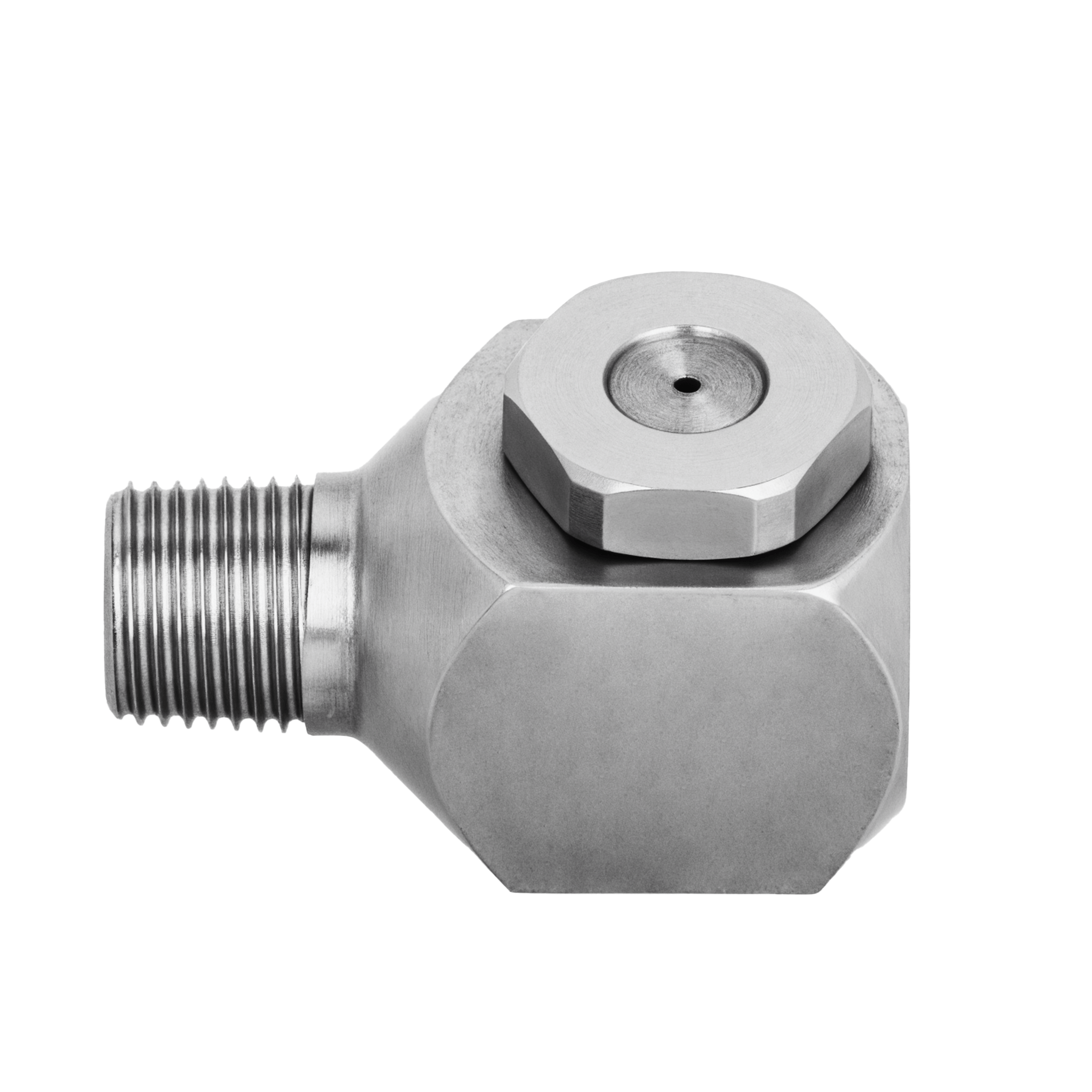

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 8-25W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 303/304 stainless steel |

| Orifice Diameter. Nom. (mm) | 4.4 |

| Orifice Diameter. Nom. (in) | 0.297 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.172 |

| Max. Free Passage Dia. (mm) | 7.5 |

Description

Product Overview

Inside the cement line's dust & pollution control stage, a plant operator relies on the NPBX-8-25W-3/8-SS to deliver a consistent hollow cone spray that minimizes airborne particulates. Constructed from 303/304 stainless steel, the nozzle withstands corrosive environments while maintaining structural integrity. Its 3/8-inch inlet allows integration with existing fluid systems, ensuring uniform coverage and reducing maintenance downtime. The operator observes improved filtration efficiency and extended equipment life due to effective mist distribution.

Applications

This nozzle plays a critical role in dust & pollution control by evenly dispersing spray to capture fine particles, thereby enhancing air quality around the processing area. Additionally, it supports cooling & quenching processes, where controlled liquid application prevents overheating and material degradation downstream.

Industries

Sectors such as automotive, building materials, and chemical processing utilize the NPBX-8-25W-3/8-SS for its corrosion resistance and reliable spray patterns, essential for maintaining operational stability. Energy, steel & metals, breweries & wineries, cement, manufacturing & assembly, and meat & poultry industries also depend on this nozzle to address specific fluid delivery challenges within their production environments.