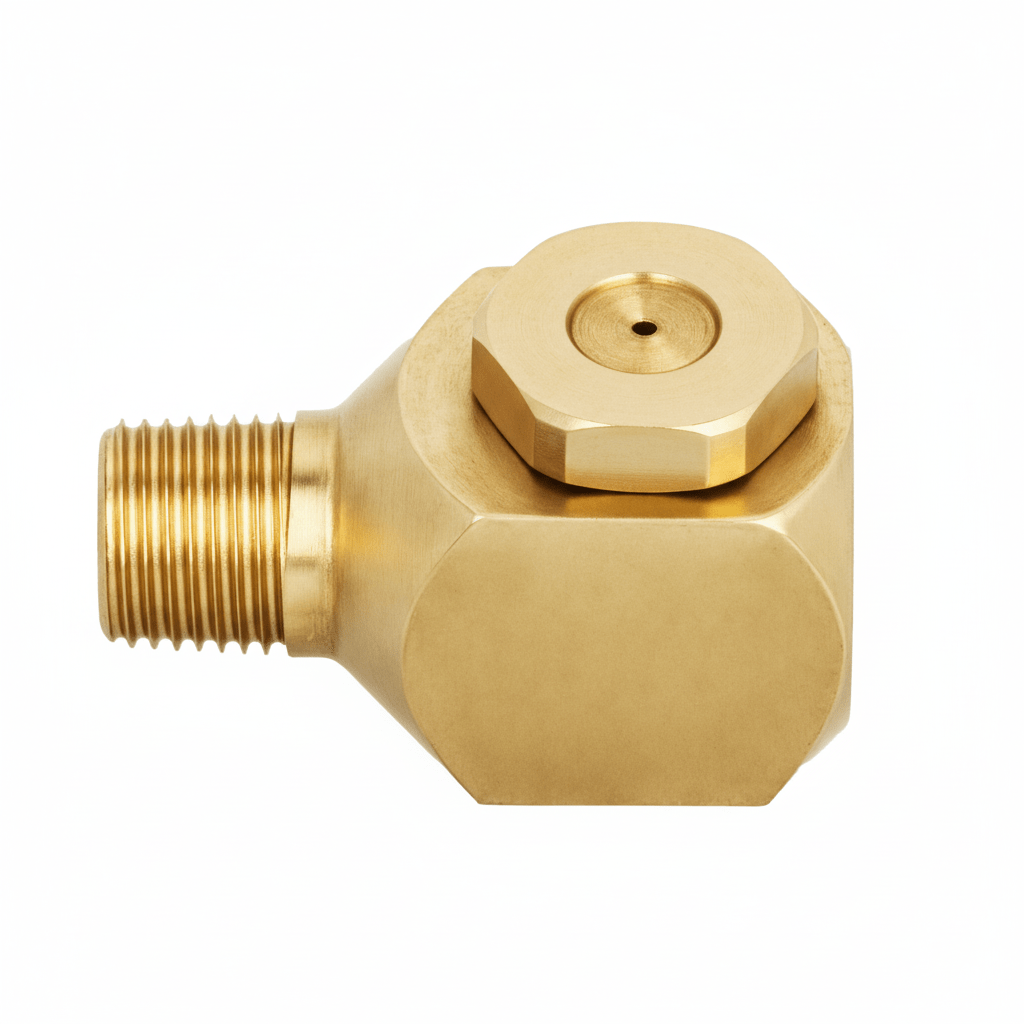

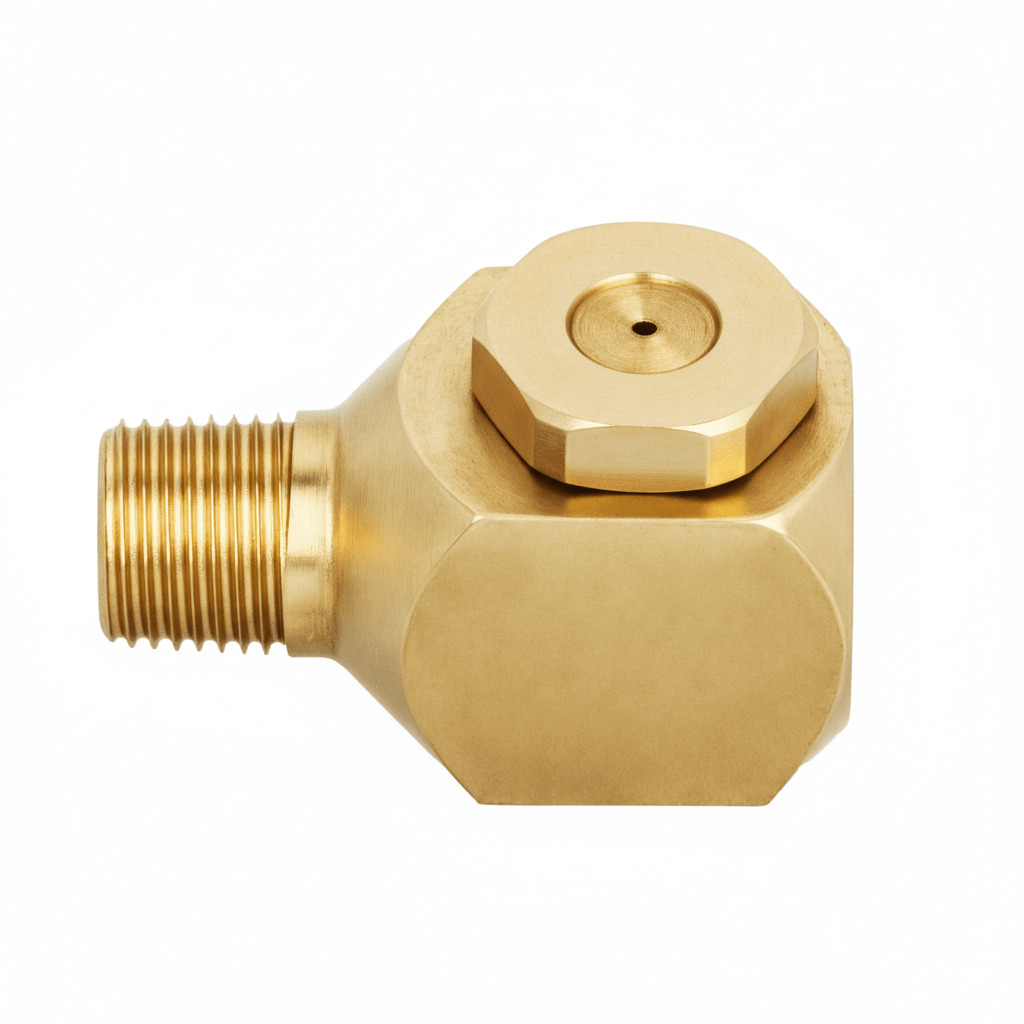

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 8-25W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | Brass |

| Orifice Diameter. Nom. (mm) | 4.4 |

| Orifice Diameter. Nom. (in) | 0.297 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.172 |

| Max. Free Passage Dia. (mm) | 7.5 |

Description

Product Overview

When cement crews manage dust & pollution control, the NPBX-8-25W-3/8 lets each plant operator achieve consistent spray coverage across large surface areas. Constructed from brass, this nozzle delivers a hollow cone spray pattern that ensures uniform droplet distribution and reliable corrosion resistance under harsh operating conditions. Operators integrate the NPBX-8-25W-3/8 easily into existing 3/8-inch inlet piping systems, enabling precise control over spray intensity and minimizing waste. This precision contributes to improved environmental compliance and optimized water usage during routine dust suppression tasks.

Applications

In cooling & quenching processes, the uniform spray pattern of the nozzle helps regulate temperatures effectively, reducing thermal stresses on metal components. Similarly, in humidification & conditioning systems, controlled droplet sizes promote stable air quality and moisture levels, which are critical to maintaining product consistency and worker safety.

Industries

The nozzle's durability and consistent spray performance make it suitable for sectors such as automotive, building materials, chemical processing, and Energy, where process reliability is essential. Additionally, steel & metals, breweries & wineries, cement, manufacturing & assembly, and meat & poultry industries rely on this nozzle for its ability to withstand corrosive environments while maintaining precise spray control.