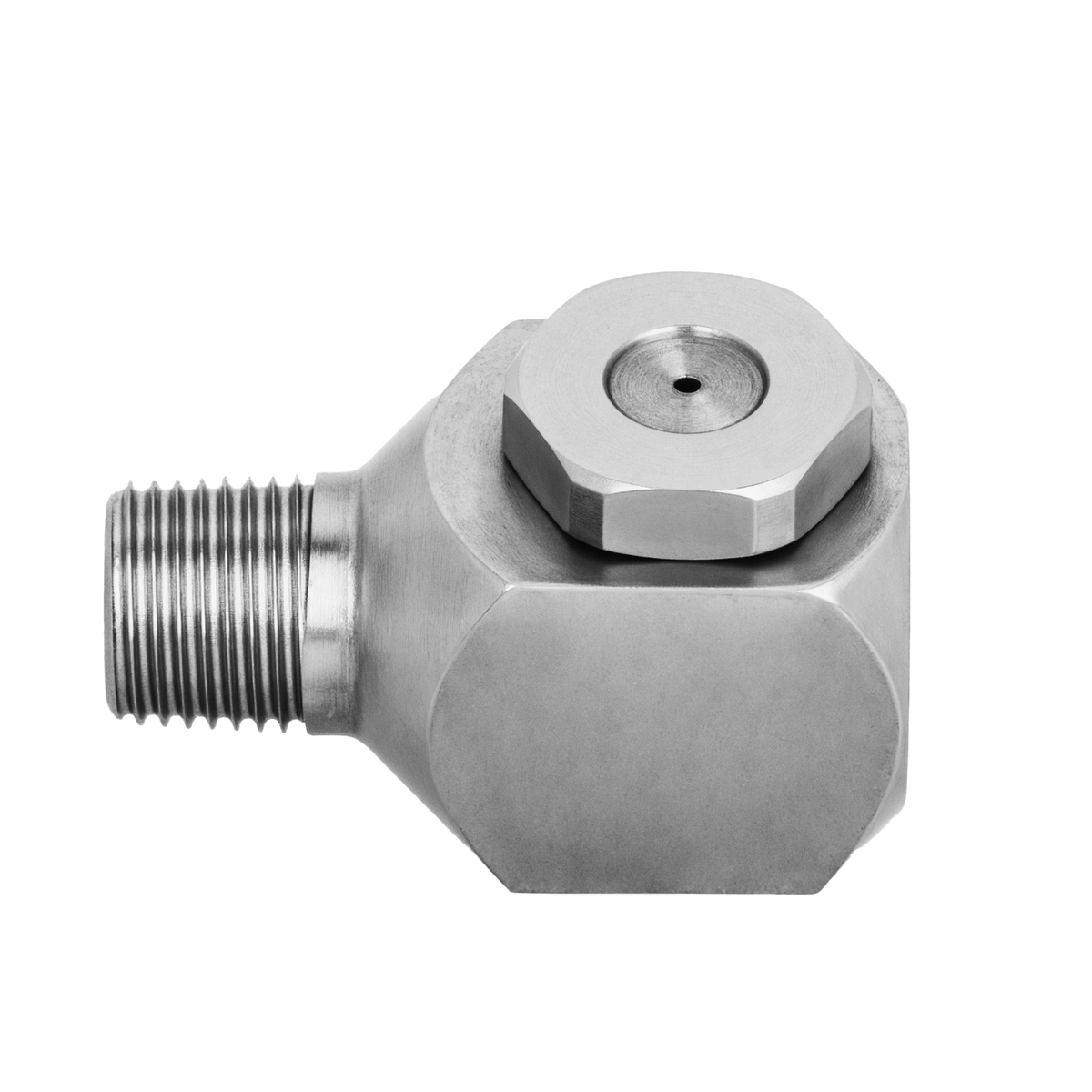

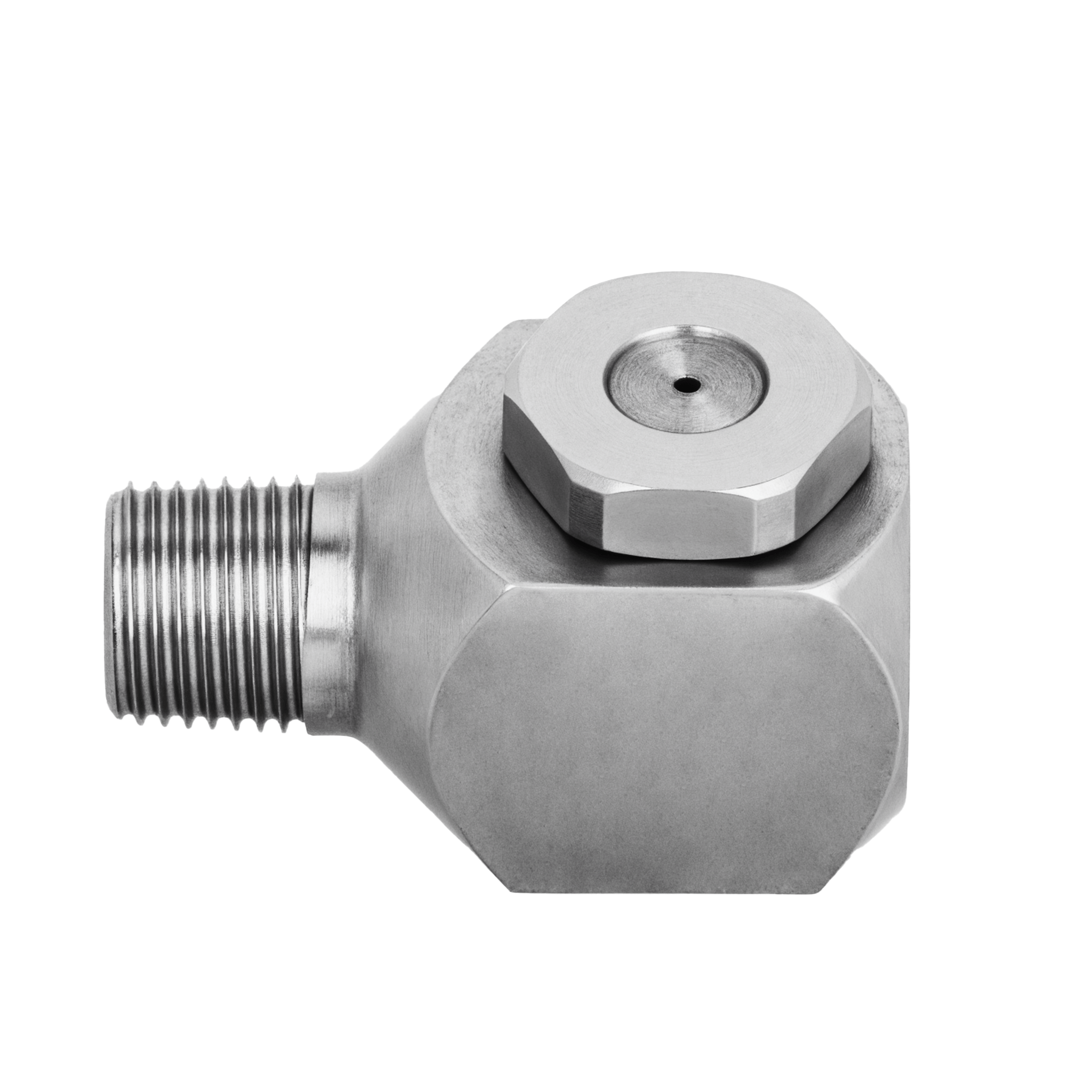

Product Parameters

| Product Family | Hollow Cone |

|---|---|

| Product Series | NPBX |

| Capacity Size | 8-15W |

| Inlet Connection Thread Type | NPT |

| Inlet Connection Gender | MALE (M) |

| Material Composition Filter | 316L stainless steel |

| Orifice Diameter. Nom. (mm) | 4.4 |

| Orifice Diameter. Nom. (in) | 0.219 |

| Inlet Connection Size (in.) | 3/8 |

| Length (mm) | 40 |

| Length (in) | 1.563 |

| Inlet Dia. Nom. (in) | 0.172 |

| Max. Free Passage Dia. (mm) | 5.6 |

Description

Product Overview

When meat & poultry crews manage specialty applications, the NPBX-8-15W-3/8-316 lets each quality manager control spray distribution with consistent, repeatable results. Operators install this precision hollow cone nozzle made from 316L stainless steel onto lines requiring corrosion-resistant components, ensuring long service life in harsh environments. The 3/8 inch inlet facilitates straightforward integration into existing piping, while the uniform spray pattern supports efficient coverage critical to process stability. Using the NPBX-8-15W-3/8-316, teams achieve targeted fluid delivery that reduces waste and maintains operational standards.

Applications

In cooling & quenching processes, the nozzle's consistent hollow cone spray aids in rapid and even temperature reduction, minimizing thermal stress on materials. For dust & pollution control, the controlled spray pattern enables effective particulate suppression, improving workplace safety and compliance.

Industries

The nozzle is favored across automotive, chemical processing, and steel & metals industries due to its corrosion resistance and reliable spray consistency under demanding conditions. Additionally, sectors such as building materials, breweries & wineries, and cement rely on its durability and integration flexibility to maintain continuous operation and product quality.